Coal gasification catalyst completely methanated by synthesis gas and preparation and application thereof

A complete methanation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbon production from carbon oxides, etc., to achieve good hydrothermal stability and improve hydrothermal stability performance and improve long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 catalyst preparation method

[0044] 393.574g Zr(NO 3 ) 4 ·3H 2 O was dispersed in 800ml of deionized water, heated to 75-80°C with stirring to dissolve it completely, and the solution was cooled to 1000ml to obtain Zr(NO 3 ) 4 solution.

[0045] Weigh 40.71g Ni(NO 3 ) 2 .6H 2 O, 39.16g (NH 4 ) 2 Ce(NO 3 ) 2 , 7.95gLa(NO 3 ) 3 .6H 2 O, 1M Zr(NO 3 ) 4 Solution 71.4ml, urea 60g, add deionized water to dissolve to 2000mL; slowly heat the above mixed solution to 90°C in a water bath, the mixture gradually becomes turbid and starts to react, keep the reaction for 40 hours, the pH value rises from 2.3 to about 7.

[0046] The above precipitate was filtered, and the filter cake was washed twice with 1000 mL of deionized water and filtered again. The obtained filter cake was dried at 110°C for 12 hours; the dried sample was placed in a muffle furnace, and the temperature increase rate was 2.5°C / min, and it was roasted at 500°C for 2 hours; the obta...

Embodiment 2

[0047] Embodiment 2 Catalyst evaluation method

[0048] The prepared catalyst samples were tested and evaluated for the methanation reaction performance of synthesis gas in a fixed-bed reactor. According to the multi-stage methanation process for preparing synthetic natural gas from coal-based syngas methanation described in the present invention, the following reaction evaluation conditions are set:

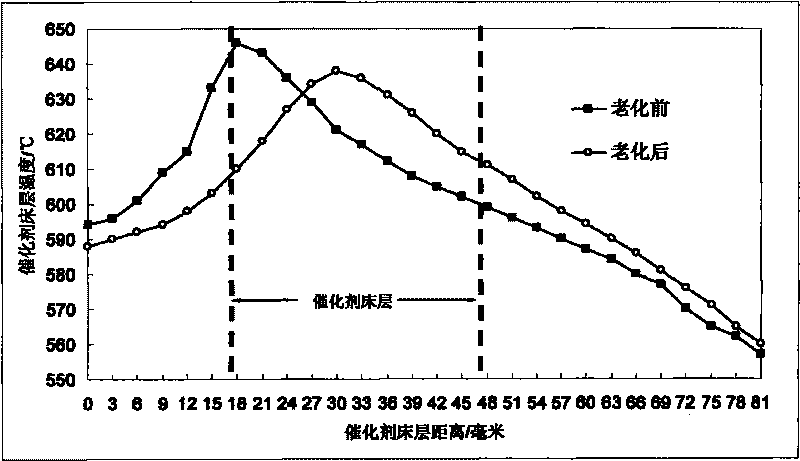

[0049] (1) One stage methanation reaction

[0050] Raw gas composition: 34.0%H 2 , 9.0% CO, 2.0% CO 2 , 39% CH 4 , 16.0%H 2 O (mole percent);

[0051] Raw material gas GHSV: 20000hr -1 (dry airspeed);

[0052] Pressure: 3.5MPa;

[0053] Catalyst bed inlet temperature: 300°C;

[0054] Catalyst bed hot spot temperature: 650°C;

[0055] Catalyst particle size: 40-60 mesh;

[0056] Catalyst bed height: 30mm.

[0057] (2) Two-stage methanation reaction

[0058] Raw gas composition: 24.0% H 2 , 2.0% CO, 5.0% CO 2 , 46.0% CH 4 , 23.0%H 2 O (mole percent);

[0059] Raw...

Embodiment 3

[0080] Example 3CeO 2 The role of the base complex oxide

[0081] What this embodiment attempts to illustrate is that CeO in the present invention 2 The influence of base composite oxide as catalyst carrier on the methanation performance of the catalyst of the present invention. Adopt the method for preparing catalyst described in embodiment 1 to prepare Al 2 o 3 -ZrO 2 Composite oxide is as the catalyst comparison example (comparison sample 1) of carrier, and the composition of comparison sample 1 is 30%NiO-36%Al 2 o 3 -24% ZrO 2 -10%La 2 o 3 .

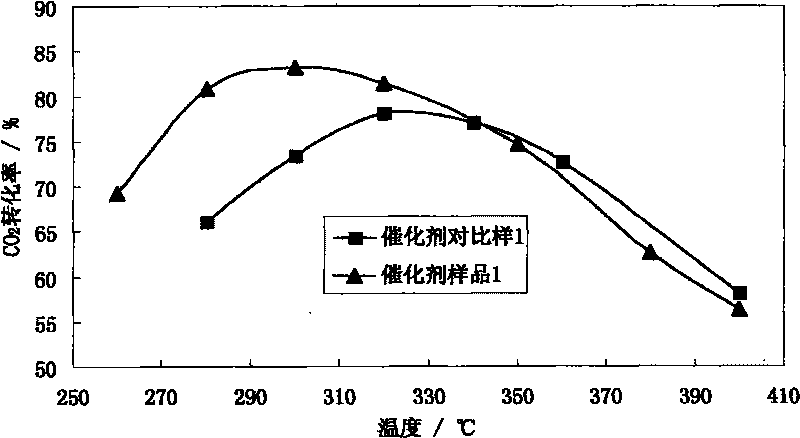

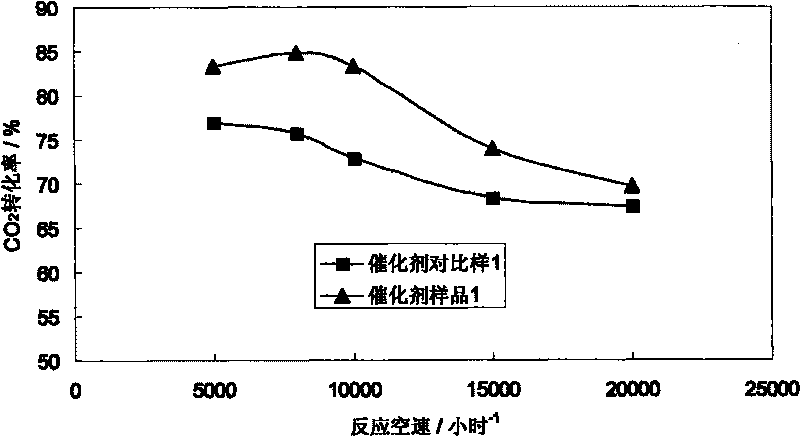

[0082] The above-mentioned catalyst sample 1 and comparative sample 1 were tested for methanation performance by adopting the processing conditions of the third stage methanation reaction, the results are shown in figure 1 and figure 2 . Depend on figure 1 Visible, with Al 2 o 3 -ZrO 2 Composite oxides as supported methanation catalysts compared to CeO 2 The catalyst of the present invention based on composite oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com