Micro-arc oxidation-electrodeposition preparation method of magnesium-based bioactive coating

A technology of micro-arc oxidation and active coating, applied in the direction of coating, anodic oxidation, electrolytic inorganic material coating, etc., to achieve the effect of matching mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

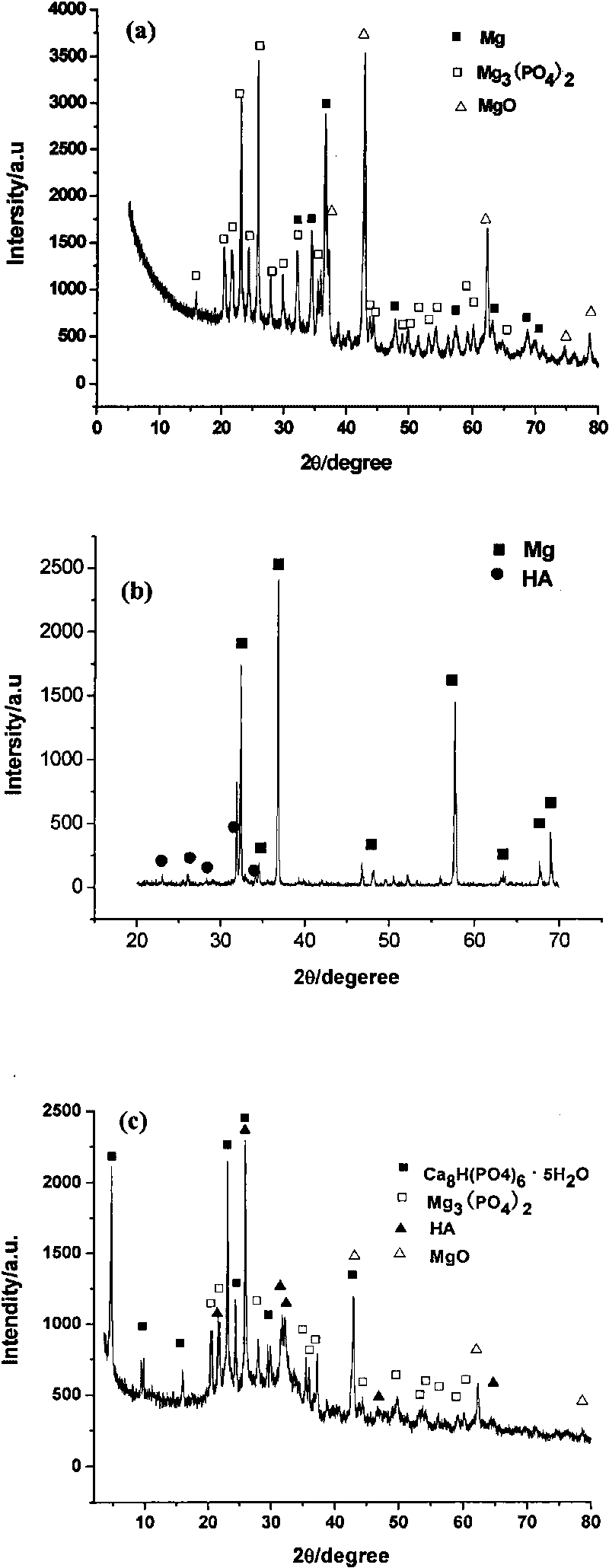

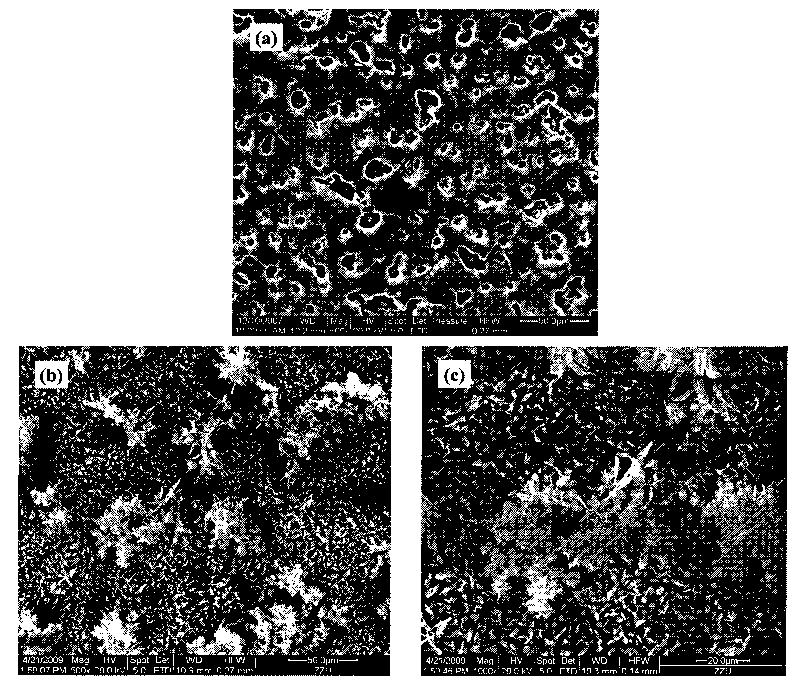

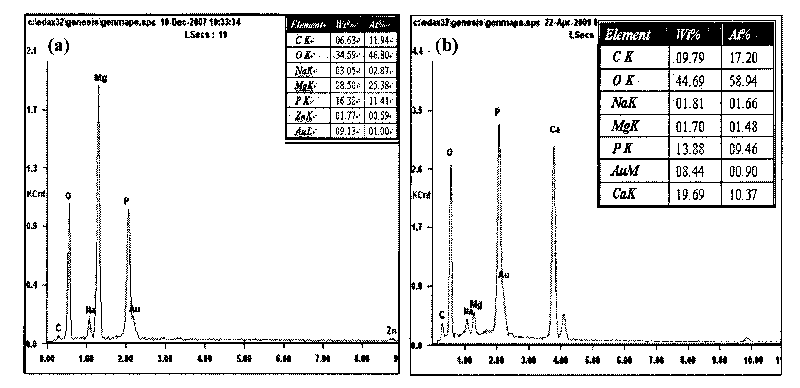

Embodiment 1

[0044] The method for preparing a biologically active coating by micro-arc oxidation-electrodeposition on the surface of Mg-2wt%Zn alloy comprises the following steps:

[0045] (1) Pretreatment base material: use 100 # 、200 # 、400 # 、600 # , 800 # 、1000 # After polishing the base material in turn with SiC metallographic sandpaper, place the base material in an acetone / absolute ethanol mixed solution with a volume ratio of 1:1 and ultrasonically clean it for 10 minutes to remove impurities and grease on the base material, and then dry it naturally at room temperature spare;

[0046] (2) Preparation of micro-arc oxidation electrolyte: micro-arc oxidation electrolyte is an aqueous solution composed of the following components: Na 3 PO 4 0.1mol / L, NaOH 0.05mol / L;

[0047] (3) Micro-arc oxidation: the magnesium-based base material processed in step (1) is used as the anode, and the stainless steel sheet is used as the cathode, and the anode and the cathode are immersed in t...

Embodiment 2

[0059] The method for preparing a bioactive coating by micro-arc oxidation-electrodeposition on the surface of Mg-3wt%Al alloy comprises the following steps:

[0060] (1) Pretreatment base material: use 100 # 、200 # 、400 # 、600 # , 800 # 、1000 # After polishing the base material with SiC metallographic sandpaper in sequence, place the base material in an acetone / absolute ethanol mixed solution with a volume ratio of 1:1 and ultrasonically clean it for 5 minutes to remove impurities and grease on the base material, and then dry it naturally at room temperature spare;

[0061] (2) Preparation of micro-arc oxidation electrolyte: micro-arc oxidation electrolyte is an aqueous solution composed of the following components: Na 3 PO 4 0.06mol / L, NaOH 0.025mol / L;

[0062] (3) micro-arc oxidation: take the magnesium-based base material processed in step (1) as the anode, and the stainless steel sheet as the cathode, and the anode and the cathode are immersed in the electrolyte p...

Embodiment 3

[0067] The method for preparing a biologically active coating by micro-arc oxidation-electrodeposition on the surface of pure magnesium (99.99wt%) alloy comprises the following steps:

[0068] (1) Pretreatment base material: use 100 # 、200 # 、400 # 、600 # , 800 # 、1000 # After polishing the base material with SiC metallographic sandpaper in sequence, place the base material in an acetone / absolute ethanol mixed solution with a volume ratio of 1:1 and ultrasonically clean it for 15 minutes to remove impurities and grease on the base material, and then dry it naturally at room temperature spare;

[0069] (2) Preparation of micro-arc oxidation electrolyte: micro-arc oxidation electrolyte is an aqueous solution composed of the following components: Na 3 PO 4 0.19mol / L, NaOH 0.075mol / L;

[0070] (3) Micro-arc oxidation: the magnesium-based base material processed in step (1) is used as the anode, and the stainless steel sheet is used as the cathode, and the anode and the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com