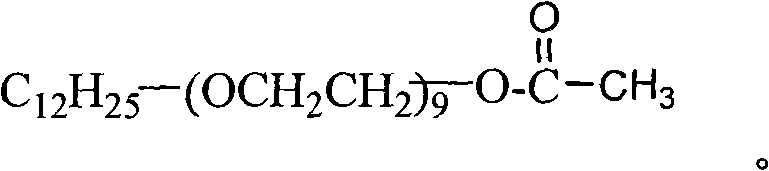

Lauryl alcohol polyoxyethylene ether acetate and cleaning agent taking lauryl alcohol polyoxyethylene ether acetate as main component

A technology of lauryl alcohol polyoxyethylene ether and acetate, applied in detergent compositions, detergent compounding agents, surface active detergent compositions, etc., can solve environmental hazards, low solubility, waste of resources and energy, etc. problem, to achieve the effect of strong compounding performance and superior compounding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

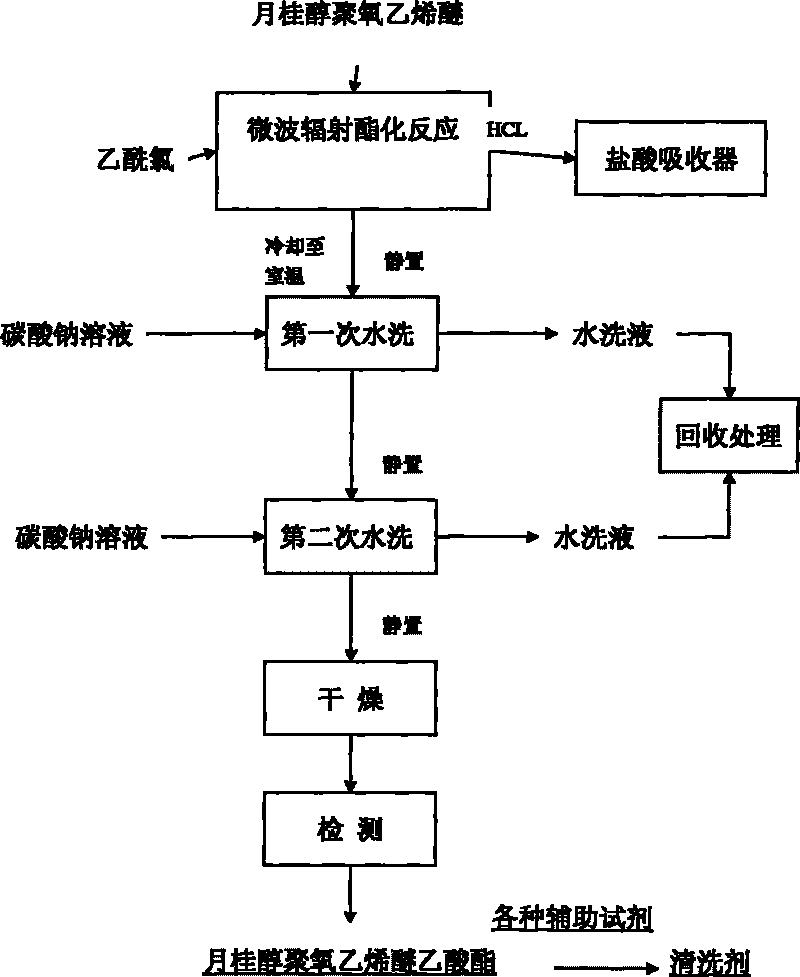

[0030] Put the measured 1mmol of polyoxyethylene lauryl ether (n=9) into a 50ml round-bottomed flask for heating; add the measured 1.00mmol of acetyl chloride into the constant pressure dropping funnel, slowly add the acetyl chloride dropwise, and the dropwise addition is completed Finally, set the microwave radiation power to 300W for 5 minutes to start the reaction. After the reaction is completed, cool to room temperature and stand still.

Embodiment 2

[0032] Put the measured 1mmol of polyoxyethylene lauryl ether (n=9) into a 50ml round-bottomed flask for heating; add the measured 1.00mmol of acetyl chloride into the constant pressure dropping funnel, slowly add the acetyl chloride dropwise, and the dropwise addition is completed Finally, set the microwave radiation power to 375W for 5 minutes to start the reaction. After the reaction is completed, cool to room temperature and stand still.

Embodiment 3

[0034] Put the measured 1mmol of polyoxyethylene lauryl ether (n=9) into a 50ml round-bottomed flask for heating; add the measured 1.00mmol of acetyl chloride into the constant pressure dropping funnel, slowly add the acetyl chloride dropwise, and the dropwise addition is completed Finally, set the microwave radiation power to 450W for 5 minutes to start the reaction. After the reaction is completed, cool to room temperature and stand still.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com