Liquid composition used for reinforcing concrete, preparation method thereof and application thereof

A liquid composition and a technology for the composition are applied in the field of liquid compositions for enhancing the surface structure of hardened concrete and the field of preparation thereof, which can solve the problems of inability to maintain for a long time and pan-alkali, cumbersome concrete weathering protection treatment process and limited enhancement effect. and other problems, to achieve the effect of improving dust and sand generation, effective environmental protection, and protection of surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

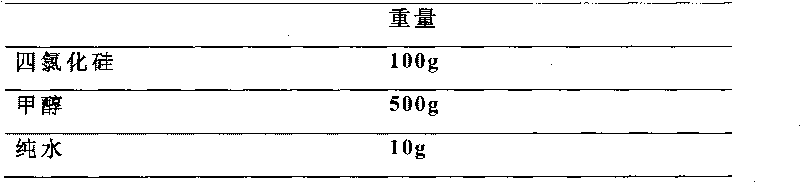

[0036] The preparation of embodiment 1 silicone polymer liquid composition

[0037]

[0038] Preparation:

[0039] At a temperature of 5°C, add a mixture of 100 grams of silicon tetrachloride liquid, 500 grams of methanol and 10 grams of water into the anticorrosion reactor to carry out the alcoholysis and hydrolysis reaction while releasing the generated gas. Finally, the reactor is heated and evaporated at the same time. A mixture of by-products such as hydrogen chloride, methanol, and methyl chloride is produced to obtain a high-concentration siloxane polymer liquid containing a small amount of chlorine. After diluting and hydrolyzing with pure water at a ratio of 1:1, the pH of the liquid was tested to be 4.8, and the solid content of the completely hydrolyzed silicon dioxide was 48% by weight.

[0040] Abrasion test:

[0041] According to the national standard GB / T 17671-1999, the weight ratio of cement, sand and water is 1 to 3 to 0.5, and the cement with the label ...

Embodiment 2

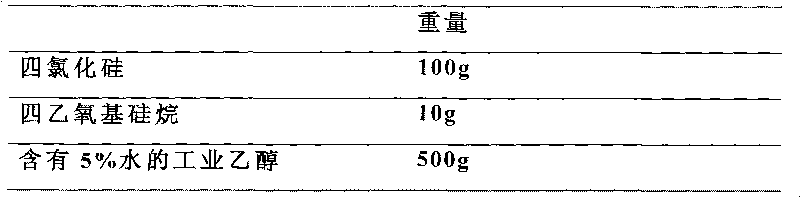

[0051] The preparation of embodiment 2 silicone polymer liquid composition

[0052]

[0053] Preparation:

[0054] At room temperature, 100 grams of silicon tetrachloride and 10 grams of tetraethoxysilane are added into a glass reactor containing 500 grams of industrial alcohol containing 5% water to carry out alcoholysis reaction and hydrolysis reaction. After the reaction is completed, Raise the temperature of the reactor while decompressing to increase the mixture of hydrogen chloride and ethanol and other organic by-products containing chlorine, and finally obtain a high-concentration silicon oxide polymer liquid containing a small amount of chlorine. The silicon dioxide solid content of the liquid after complete hydrolysis is 41%. (weight), after diluting with pure water in a ratio of 1:1, the pH is 5.8.

[0055] Abrasion test:

[0056] According to the national standard GB / T 17671-1999, cement, sand and water are used in a weight ratio of 1 to 3 to 0.5, and two ceme...

Embodiment 3

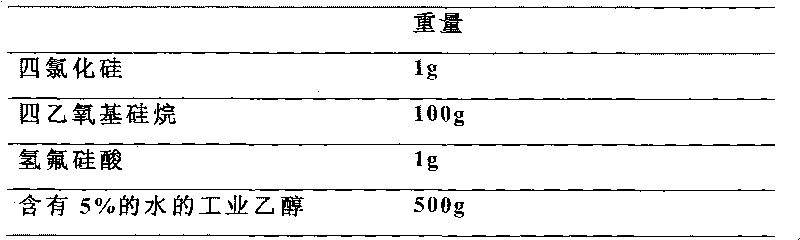

[0057] The preparation of embodiment 3 silicone polymer liquid composition

[0058]

[0059] Preparation:

[0060]At room temperature, 1 gram of silicon tetrachloride, 100 grams of tetraethoxysilane, and 1 gram of hydrofluorosilicic acid are added into a glass reactor containing 500 grams of industrial ethanol containing 5% water to carry out alcoholysis reaction and Hydrolysis reaction, after the reaction is completed, the reactor is heated up and the mixture of hydrogen chloride and ethanol and other organic by-products containing chlorine are distilled out at the same time, and finally a high-concentration siloxane polymer liquid containing a small amount of chlorine and fluorine is obtained. The liquid after complete hydrolysis The silica solids content was 45% by weight and the pH was 5.8.

[0061] Abrasion test:

[0062] According to the national standard GB / T 17671-1999, the weight ratio of cement, sand and water is 1 to 3 to 0.5, and the cement, fine sand and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com