Molybdenum disulfide nano tube and preparation method thereof

A molybdenum disulfide and nanotube technology, which is applied in the field of nanomaterials, can solve the problems of unsolved size and size distribution of molybdenum disulfide nanotubes, and achieves a simple and easy-to-control production process, low cost, and uniform pipe diameter distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take 0.26 g of ammonium thiomolybdate, dissolve it in 10 mL of dimethyl sulfoxide, and filter it to prepare a 0.1 mol / L precursor solution. Immerse the commercial AAO template in the precursor solution for 10 minutes, and then add the AAO template Place in an oven at 70°C for 5 minutes to fully volatilize the dimethyl sulfoxide solvent, and repeat the process 5 times; put the AAO template loaded with the precursor into a horizontal quartz tube furnace, at a flow rate of 200mL / min Inject 10% H 2 / N 2 The mixed gas (reducing gas H in the mixed gas 2 with protective gas N 2 The volume ratio is 1:9), and at the same time, the temperature in the quartz tube furnace is raised to 450°C at a heating rate of 10°C / min, kept for 1h to fully react, then naturally cooled to room temperature, and the introduction of H 2 / N 2 Mixed gas to get black molybdenum disulfide nanotubes.

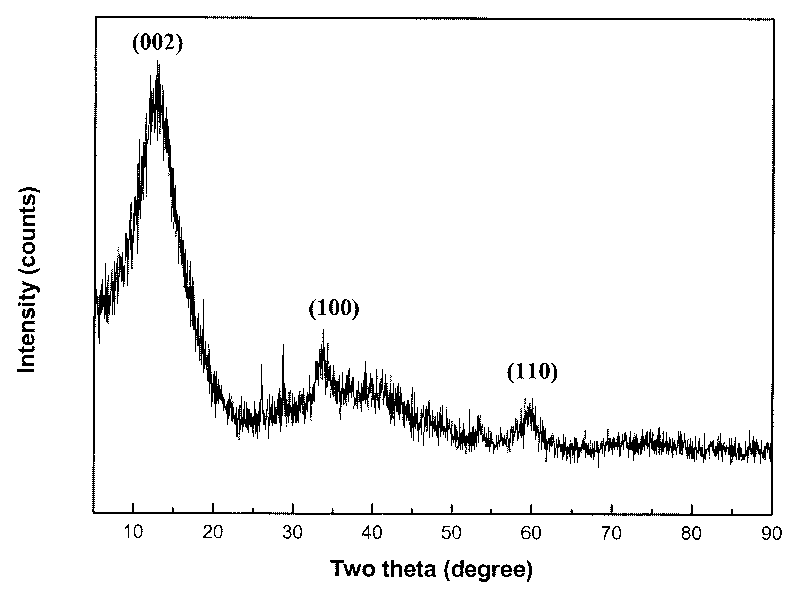

[0016] Carry out X-ray diffraction analysis to the product of present embodiment, gained XRD collec...

Embodiment 2

[0019] Take 0.26 g of ammonium thiomolybdate, dissolve it in 10 mL of dimethyl sulfoxide, and filter it to prepare a 0.1 mol / L precursor solution. Immerse the commercial AAO template in the precursor solution for 10 minutes, and then add the AAO template Place it in an oven at 70°C for 5 minutes to volatilize the dimethylsulfoxide solvent, and repeat this process 7 times; put the AAO template loaded with the precursor into a horizontal quartz tube furnace, and pass through it at a flow rate of 200mL / min. into 10% H 2 / N 2 The mixed gas (reducing gas H in the mixed gas 2 with protective gas N 2 The volume ratio is 1:9), and at the same time, the temperature in the quartz tube furnace is raised to 550°C at a heating rate of 10°C / min, kept for 1h to fully react, then naturally cooled to room temperature, and the introduction of H 2 / N 2 Mixed gas to get black molybdenum disulfide nanotubes.

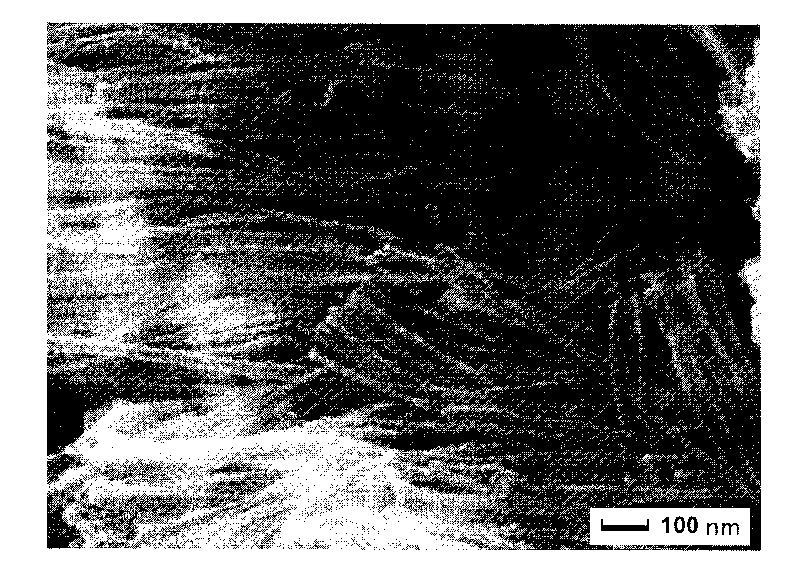

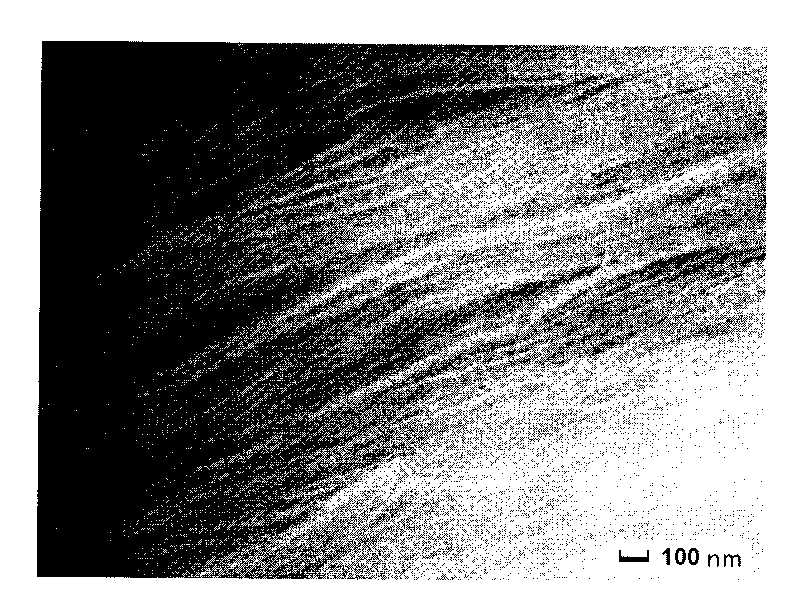

[0020] The product of the present embodiment is scanned by electron microscope to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com