Red copper brass new technique used by ore-smelting electric furnace

A submerged heat electric furnace and new process technology, applied in the field of copper tile manufacturing, can solve the problems of affecting mechanical properties and electrical conductivity, excessive power consumption, poor compactness, etc., to eliminate insufficient welding strength, reduce copper loss, mechanical The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

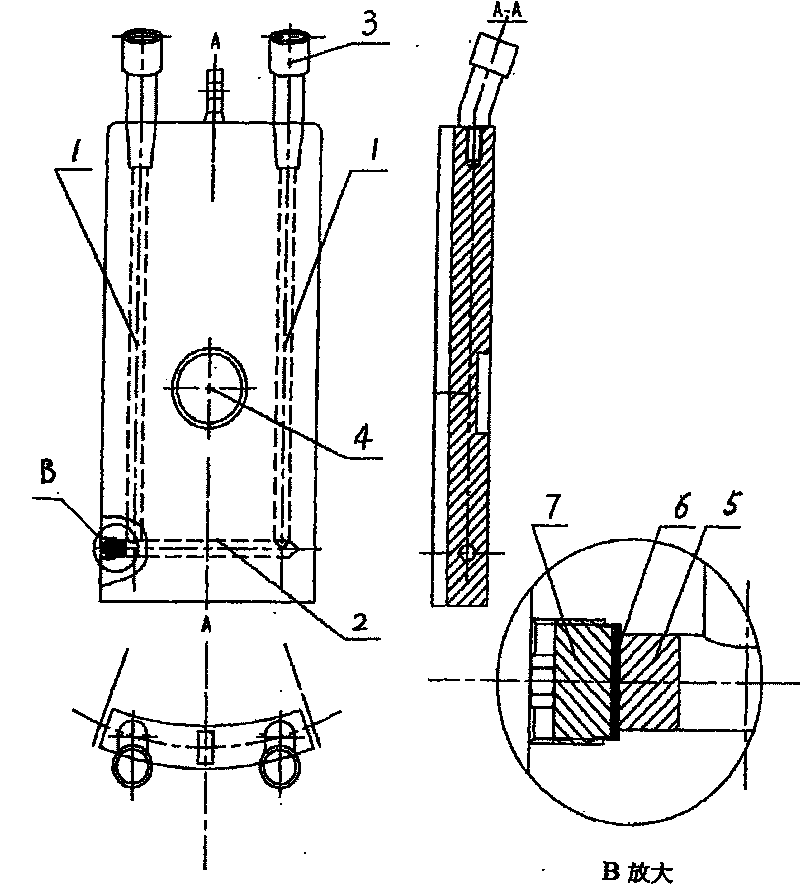

[0025] see figure 1 and figure 2 , the specific manufacturing process of the present invention is as follows steps:

[0026] 1. Purchase of raw materials: high-purity cathode copper must be used, in which the purity (weight content) of copper is 99.92%-99.96%, and the preferred value is 99.95%, so as to ensure that the copper material has good performance during the smelting process and the material enters the factory Afterwards, it must be re-inspected before it can be used.

[0027] 2. Smelting and casting: After preheating to 300°C-400°C in a 200KVA / 1.5T power frequency induction furnace, slowly put in electrolytic copper layer by layer for smelting. After about 4 hours, the electrolytic copper is completely melted, and the surface is filled with charcoal to ensure complete coverage. The charcoal is burned in the copper to achieve the purpose of deoxidation, and the temperature is further raised and the temperature of the copper water is measured with an ultrasonic therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com