Method for preparing titanium dioxide photocatalysis multi-layer film with interface defect

A titanium dioxide and multi-layer film technology, applied in the field of photocatalysis, can solve the problems of low photocatalytic efficiency of titanium dioxide photocatalyst and easy disappearance of surface defect sites, achieve good photo-induced hydrophilicity, improve photocatalytic efficiency, and avoid defects. the drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

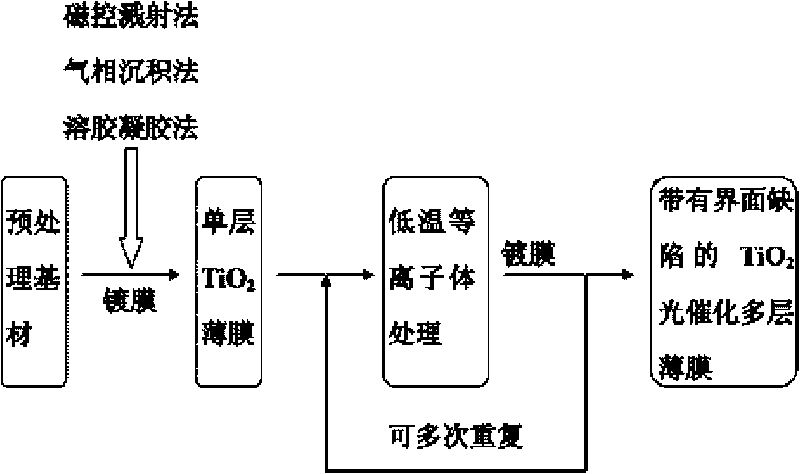

[0013] Concrete preparation steps are as follows:

[0014] (1) Using one or more combinations of magnetron sputtering, vapor deposition, liquid deposition or sol-gel methods to coat a clean substrate to be coated to obtain a titanium dioxide film coated matrix;

[0015] (2) Put the substrate after coating into the plasma treatment chamber of the plasma reactor, pass one or more medium gases in hydrogen, nitrogen, helium or argon, and adjust each in the treatment chamber according to the above conditions. Parameters (the more worrying condition parameters are: evacuate to a vacuum degree of 3Torr, adjust the average current density of the discharge area to 5mA / cm 2 , discharge plasma treatment 1 ~ 30min);

[0016] (3) Rapidly coat one deck of titanium dioxide film on the surface of titanium dioxide film after low-temperature plasma treatment. This coating method also adopts one of magnetron sputtering, vapor deposition, liquid deposition or sol-gel method. One or more combin...

Embodiment 1

[0020] TiO with interfacial defects 2 Preparation of multilayer photocatalytic thin films

[0021] Using the sol-gel membrane method, a pretreated 75mm×25mm×1.2mm clean quartz glass piece was immersed in TiO 2 In the sol, a uniform layer of TiO is coated on the surface of the quartz glass sheet by infiltration-pulling 2 Thin film, the soaking time is 1min, and the pulling speed is 2cm / min. Put the coated quartz sheet into a constant temperature oven at 150°C for 10 minutes and take it out. After cooling down to room temperature, put it into a low-temperature plasma treatment chamber. Introduce the medium gas helium and evacuate it to a vacuum degree of 3 Torr. Adjust the average discharge area. The current density is 5mA / cm 2 , discharge treatment for 5min. After taking it out, quickly immerse the plasma-treated coated quartz wafer into the TiO 2 sol, and then re-plate a layer of uniform TiO on its surface in the same way as above 2 After the film layer is completed, put...

Embodiment 2

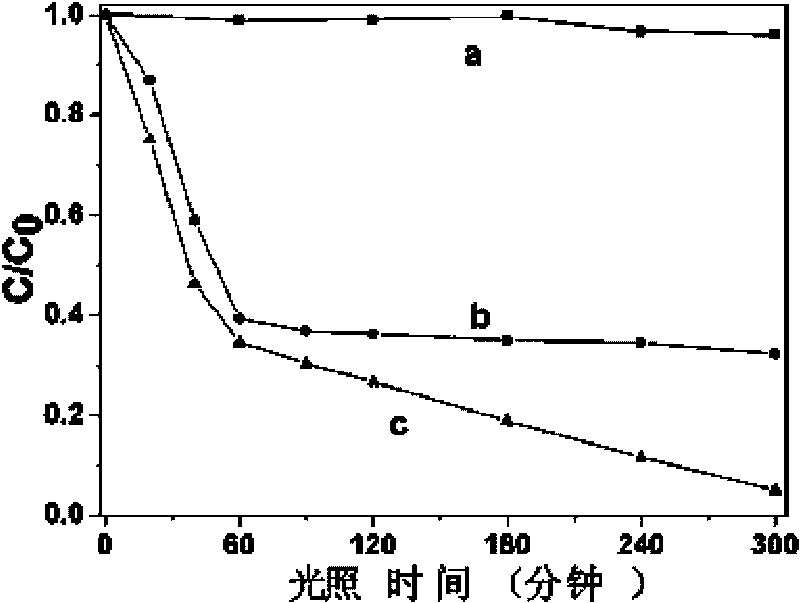

[0023] TiO with interfacial defects 2 Photoinduced hydrophilic properties of photocatalytic multilayer films

[0024] Evaluation of TiO with interfacial defects 2 Photoinduced hydrophilic properties of photocatalytic multilayer films by measuring water droplets on TiO 2 The photohydrophilicity of the film is measured by the change of contact angle on the film surface with the light time. The water droplet contact angle was measured by a Dataphysics-OCA20 optical contact angle meter. The experimental water was deionized water, and the volume of the water droplet was 5 μL. The light source used a Philips TL / 05 4W ultraviolet lamp with a dominant wavelength of 365 nm. The photo-induced hydrophilic properties of the film under different light time are as follows: figure 2 shown. Curve a is TiO 2 The photoinduced hydrophilic change of the surface of the double-layer film, after 15 minutes of ultraviolet light irradiation, the water droplet contact angle on the film surface dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com