Titanium alloy piece with anti-cavitation property on surface and preparation method thereof

A technology of titanium alloy parts and processing methods, which is applied in the direction of metal processing equipment, manufacturing tools, building components, etc., can solve the problems of long processing cycle, easy deformation of workpieces, weak bonding force, etc., and achieve short processing cycle and anti-cavitation corrosion Improved wear characteristics and reduced workpiece distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

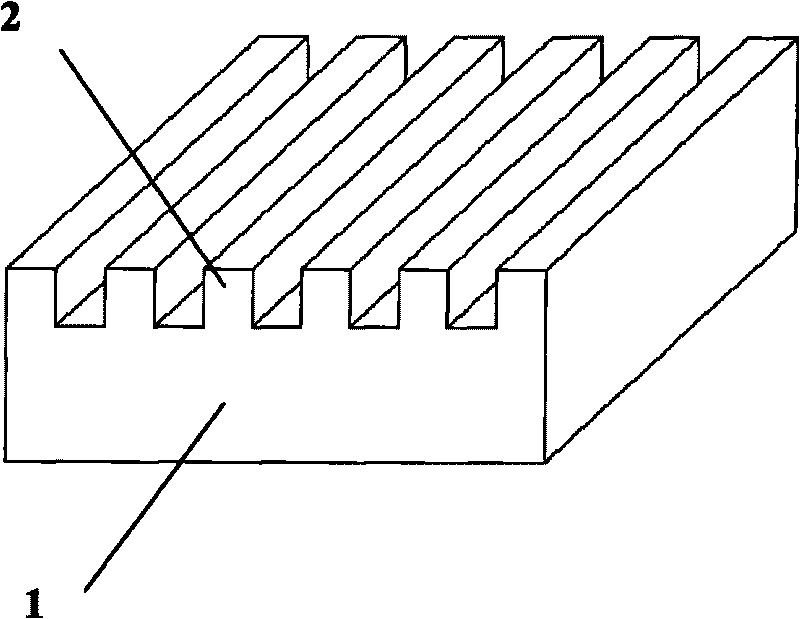

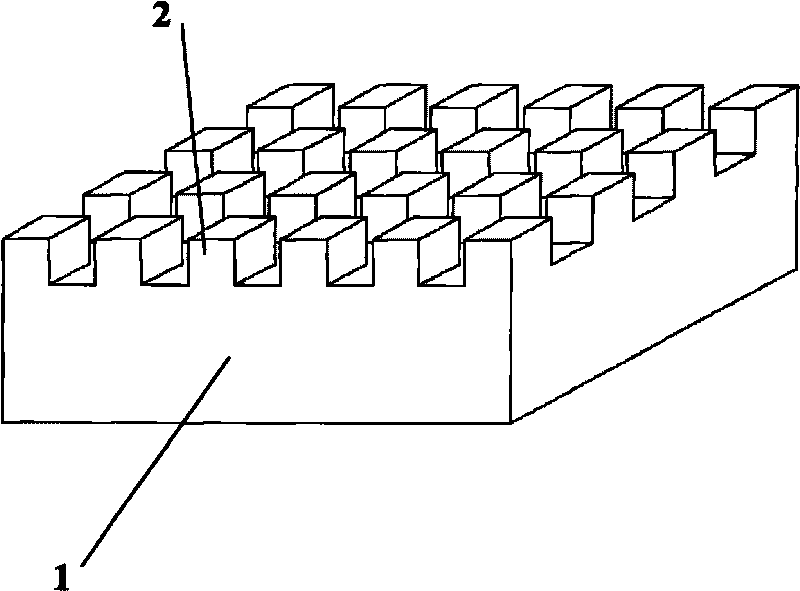

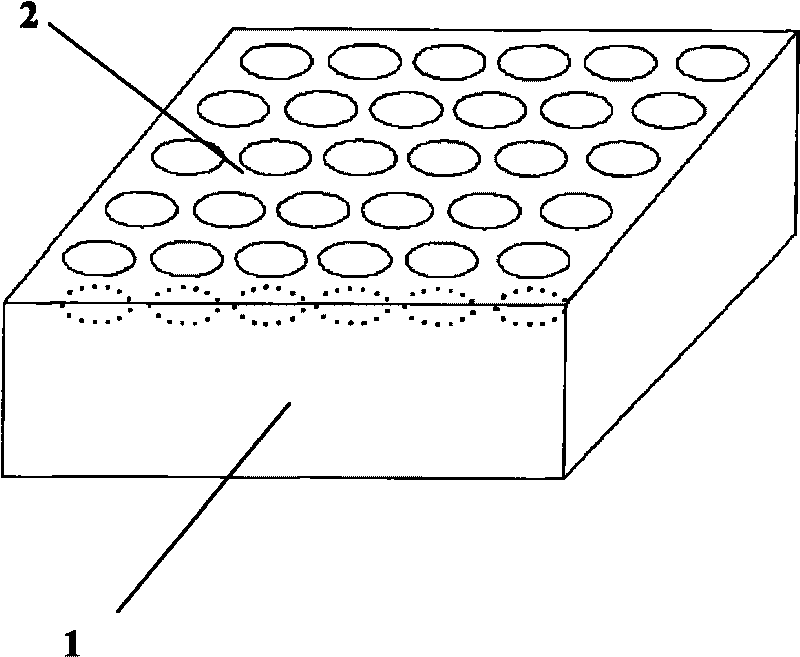

[0019] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a titanium alloy part with cavitation resistance on the surface includes a substrate 1 and a surface texture layer 2, and the surface texture layer 2 has a textured structure processed by laser. The texture structure is grid or straight line or point texture.

[0020] A method for processing a titanium alloy piece whose surface has anti-cavitation properties comprises the following steps:

[0021] A. After the titanium alloy workpiece substrate 1 is pretreated, put it into acetone, ethanol and pure water in sequence, perform ultrasonic cleaning with a numerical control ultrasonic cleaning machine for 3 minutes, and dry it with a hair dryer;

[0022] B. Process the texture structure on the surface of the titanium alloy workpiece with a laser processor, and prepare the titanium alloy surface texture layer 2 with a pitch of 50 μm and 100 μm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com