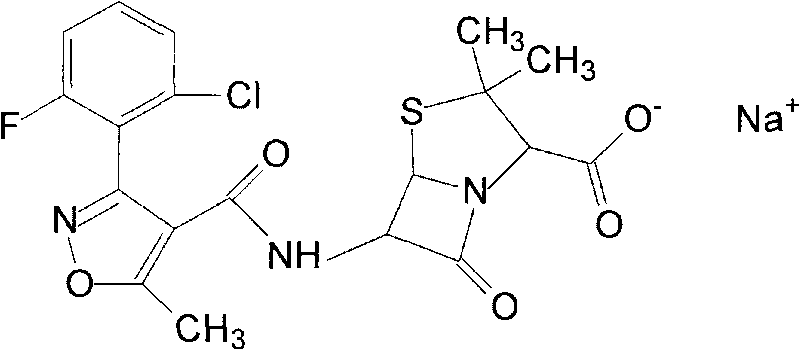

Flucloxacillin sodium suspension and new application thereof

A technology of flucloxacillin sodium and powder injection, which is applied in the field of a new dosage form of flucloxacillin sodium, which can solve the problems of unstable quality of flucloxacillin sodium, improve bioavailability and increase safety and stability, avoiding the effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

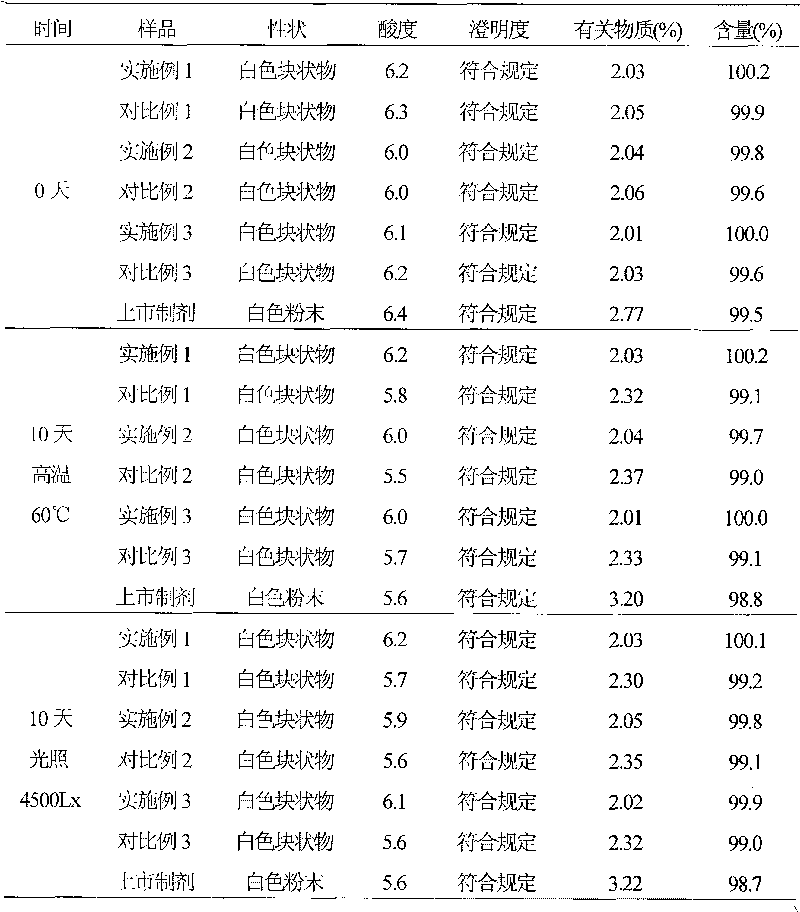

Examples

Embodiment 1

[0032] The preparation of embodiment 1 flucloxacillin sodium suspension powder injection

[0033] Prescription (100 bottles):

[0034] Flucloxacillin Sodium 50g

[0035] Polyvinyl alcohol 200g

[0036] Cholesterol 50g

[0037] Mannitol 66.7g

[0038] Trehalose 133.3g

[0039] Preparation Process:

[0040] (1) Add 200g of polyvinyl alcohol and 50g of cholesterol into 1600ml of water for injection, then add 50g of flucloxacillin sodium and mix evenly, heat and stir in a water bath at 80°C until molten;

[0041] (2) Keeping the above liquid at 70-90°C for 10 minutes with a tissue masher to shear and stir at a speed of 15,000 r / min to obtain a primary emulsion, and then circulate and emulsify it through a high-pressure homogenizer for 5 times to obtain an emulsion;

[0042] (3) Add 66.7g of mannitol and 133.3g of trehalose to the emulsion, dissolve, filter, subpackage, and freeze-dry to obtain flucloxacillin sodium suspension powder injection.

Embodiment 2

[0051] The preparation of embodiment 2 flucloxacillin sodium suspension powder injection

[0052] Prescription (100 bottles):

[0053] Flucloxacillin Sodium 100g

[0054] Polyvinyl alcohol 640g

[0055] Cholesterol 160g

[0056] Mannitol 600g

[0057] Glucose 600g

[0058] Preparation Process

[0059] (1) Add 640g of polyvinyl alcohol and 160g of cholesterol into 10000ml of water for injection, then add 100g of flucloxacillin sodium and mix evenly, heat and stir in a water bath at 90°C until molten;

[0060] (2) Keeping the above liquid at 70-90°C for 20 minutes with a tissue masher to shear and stir at a speed of 10,000 r / min to obtain a primary emulsion, and then circulate and emulsify it through a high-pressure homogenizer for 4 times to obtain an emulsion;

[0061] (3) Add 600g of mannitol sugar and 600g of glucose to the emulsion, dissolve, filter, subpackage, and freeze-dry to obtain flucloxacillin sodium suspension powder injection.

Embodiment 3

[0070] The preparation of embodiment 3 flucloxacillin sodium suspension powder injection

[0071] Prescription (100 bottles):

[0072] Flucloxacillin Sodium 50g

[0073] Polyvinyl alcohol 260g

[0074] Cholesterol 65g

[0075] Sorbitol 300g

[0076] Lactose 100g

[0077] Preparation Process

[0078] (1) Add 260g of polyvinyl alcohol and 65g of cholesterol into 3500ml of water for injection, then add 50g of flucloxacillin sodium and mix evenly, heat and stir in a water bath at 70°C until molten;

[0079] (2) The above liquid was kept warm at 70-90°C and was sheared and stirred for 20 minutes with a tissue masher at a speed of 13000r / min to obtain a primary emulsion, which was then circulated and emulsified by a high-pressure homogenizer for 5 times to obtain an emulsion;

[0080] (3) Add 300 g of sorbitol and 100 g of lactose to the emulsion, dissolve, filter, subpackage, and freeze-dry to obtain flucloxacillin sodium suspension powder injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com