High-temperature resistant low-noise drain pipe

A low-noise, drainpipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of water pipe rupture, poor impact resistance, poor environmental performance, etc., and achieve simple production process and strong high temperature resistance , The effect of low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

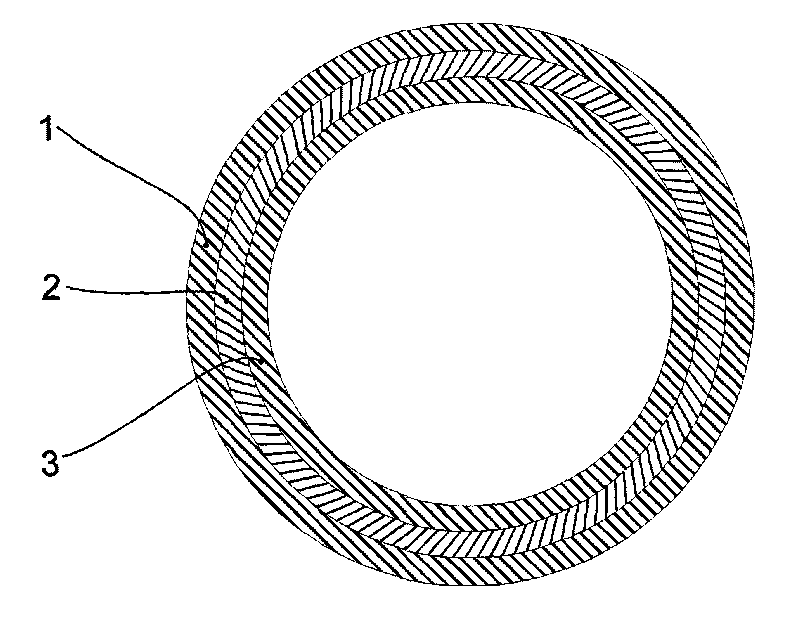

[0024] Its preferred proportioning ratio of the composite material that outer layer (1) and internal layer (3) adopts among the present invention is:

[0025] Random copolymer polypropylene 76%,

[0027] Masterbatch 2%,

[0028] What needs to be pointed out here is that this example only illustrates the better solution. In actual use, the composition of the composite material can make the product achieve better high temperature resistance and low noise effect within the following ranges, namely:

[0029] Random copolymerized polypropylene 50-90%,

[0030] Calcium carbonate 9-49%,

[0031] Masterbatch 1-5%,

[0032] The proportioning ratio of the polymer filler adopted in the middle layer (2) is:

[0033] Block copolymer polypropylene 20-80%,

[0034] Silica 20-80%,

[0035] Lubricant 0.3-2%,

[0036] Masterbatch 0.5-5%,

[0037] The production principle of the high-temperature-resistant and low-noise drainage pipe of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com