Preparation method of electric-conduction polyimide film

A technology of polyimide film and polyamic acid resin, which is applied to conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as no progress, and achieve the effects of fast heating speed, easy dispersion and uniform power distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

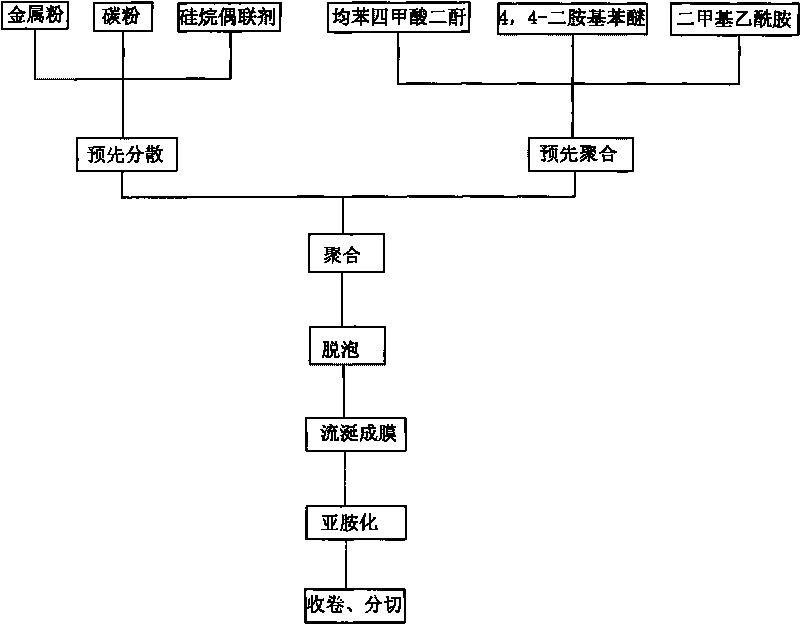

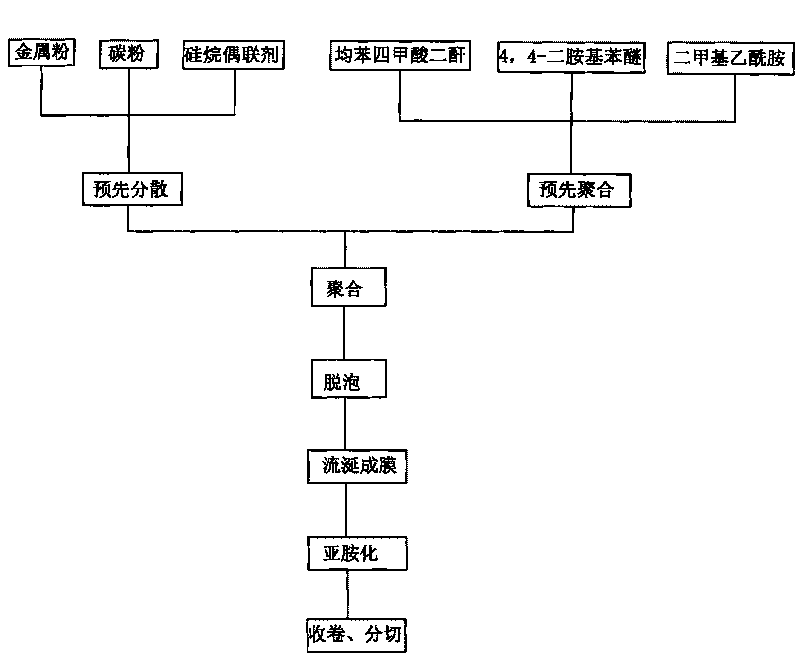

[0022] Such as figure 1 As shown, the principle on which the preparation method is based is that both the conductive metal powder and the conductive carbon powder are conductive materials and are easy to disperse, so the nano-scale conductive metal powder and carbon powder are evenly dispersed in the polyamic acid resin, and then passed through the salivation process. And imidization treatment to make a film with good electrical conductivity and mechanical properties. The preparation method is as follows: Step 1: Put the conductive nanoparticles in an organic solvent and pre-disperse them after high-temperature treatment in a high-shear disperser, so that the surface of the conductive particles is covered with a layer of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com