Preparation method of gradient porous alumina ceramics

A technology of alumina ceramics and gradient porosity, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of low porosity, difficult control of pore shape, poor pore distribution, etc., and achieve high porosity, good industrial application prospects, The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

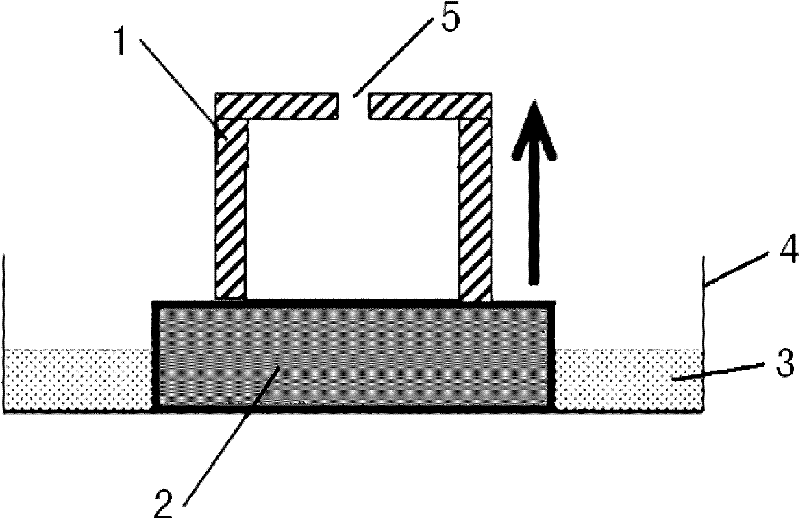

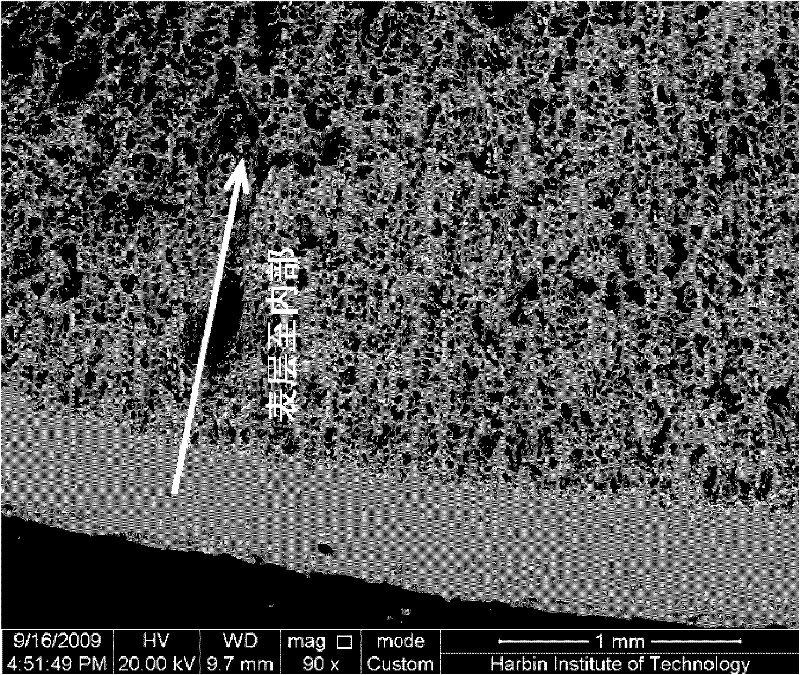

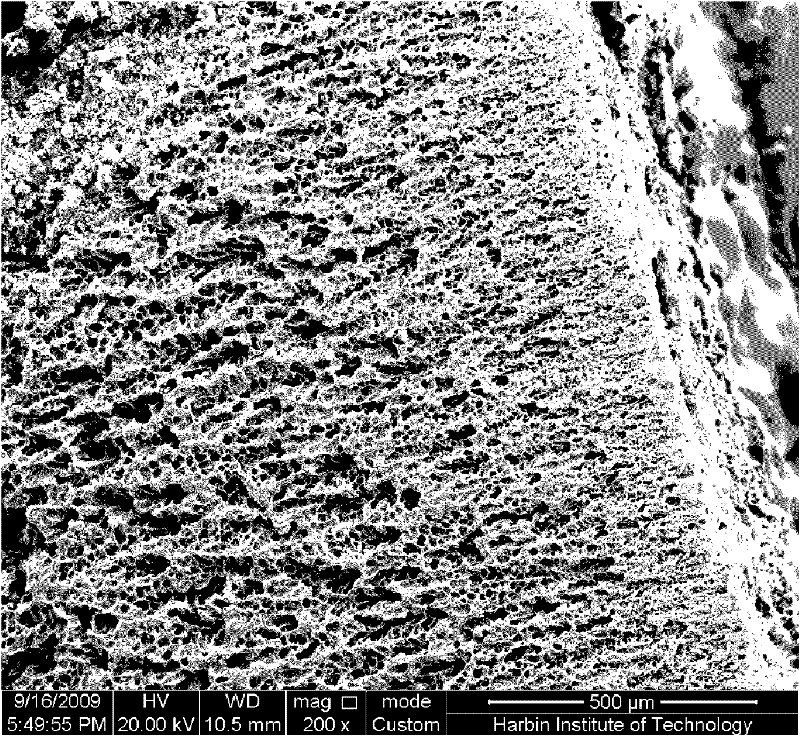

[0016] Specific embodiment one: the preparation method of gradient porous alumina ceramics in this embodiment is realized through the following steps: one, alumina powder, camphene (C 10 h 16 ) and fatty acid polycondensate are mixed and placed in a constant temperature ball mill, ball milled at 50-60°C for 20-30 hours to obtain a mixed slurry, wherein the volume ratio of alumina powder to camphene is 1:4-19, fatty acid polycondensate The quality is 1%~3% of the total mass of alumina powder and camphene, and the polycondensate of fatty acid is Texaphor963; 2. After the mold is immersed in liquid nitrogen for 1~3min, the slurry obtained in step 1 is poured into the mould, Let it stand for another 30-60 minutes, and then demould to obtain the green body, wherein the liquid nitrogen liquid level is located at 1 / 2-2 / 3 of the bottom of the mold based on the bottom surface of the mold; 3. Put the green body at room temperature and air atmosphere conditions Place it under the ground...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the particle size of the alumina powder in step 1 is 0.5-1 μm. Other steps and parameters are the same as those in Embodiment 1.

[0021] The alumina powder in this embodiment is a commercially available product.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass purity of camphene in step 1 is greater than 97%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0023] Camphene (C 10 h 16 ) is a commercially available product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com