Polystyrene group hierarchical mesoporous carbon material, preparation method and application thereof

A polystyrene and polystyrene solution technology, applied in the field of materials, can solve the problems of unfriendly environment, low porosity, harsh conditions, etc., and achieve the effects of simple process, low equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A polystyrene-based hierarchical porous carbon material and a preparation method thereof, including the following steps:

[0028] (1) In a 250ml container, add 5.0g linear polystyrene (commercial linear polystyrene resin, model: PS525, Sinopec Guangzhou Branch, the same below) and 100ml anhydrous carbon tetrachloride, stir at room temperature After it is completely dissolved, a polystyrene carbon tetrachloride solution with a concentration of 5% is obtained;

[0029] (2) Add 12.0g of reaction catalyst anhydrous aluminum trichloride and 100ml of anhydrous carbon tetrachloride into a 250ml reaction kettle, set the temperature of the constant temperature water bath at 75℃, and start stirring after condensed water is added while loading Drying tube for anhydrous calcium chloride; after refluxing for 40 minutes, slowly and uniformly (100ml solution for about 30 seconds) add the above polystyrene solution to it, heating to reflux under magnetic stirring, and continuous Friedel-Cra...

Embodiment 2

[0035] A polystyrene-based hierarchical porous carbon material and a preparation method thereof, including the following steps:

[0036] (1) In a 250ml container, add 5.0g linear polystyrene and 100ml anhydrous carbon tetrachloride successively, stir at room temperature until it is completely dissolved to obtain a polystyrene carbon tetrachloride solution with a concentration of 5%;

[0037] (2) Add 12.0g of reaction catalyst anhydrous aluminum trichloride and 100ml of anhydrous carbon tetrachloride into a 250ml reaction kettle, set the temperature of the constant temperature water bath at 75℃, and start stirring after condensed water is added while loading Drying tube for anhydrous calcium chloride; after refluxing for 40 minutes, slowly and uniformly (100ml solution for about 30 seconds) add the above polystyrene solution to it, heating to reflux under magnetic stirring, and continuous Friedel-Crafts reaction for 48 hours;

[0038] (3) Add 100ml of a mixed solvent of 95% ethanol + ...

Embodiment 3

[0041] A polystyrene-based hierarchical porous carbon material and a preparation method thereof, including the following steps:

[0042] (1) In a 250ml container, add 5.0g linear polystyrene and 100ml anhydrous carbon tetrachloride successively, stir at room temperature until it is completely dissolved to obtain a polystyrene carbon tetrachloride solution with a concentration of 5%;

[0043] (2) Add 12.0g of reaction catalyst anhydrous aluminum trichloride and 100ml of anhydrous carbon tetrachloride into a 250ml reaction kettle, set the temperature of the constant temperature water bath at 75℃, and start stirring after condensed water Drying tube for anhydrous calcium chloride; after refluxing for 40 minutes, slowly and uniformly (100ml solution for about 30 seconds) add the above polystyrene solution to it, heating to reflux under magnetic stirring, and continuous Friedel-Crafts reaction for 48 hours;

[0044] (3) Add 100ml of a mixed solvent of 95% ethanol + water (v / v=4:1) to term...

PUM

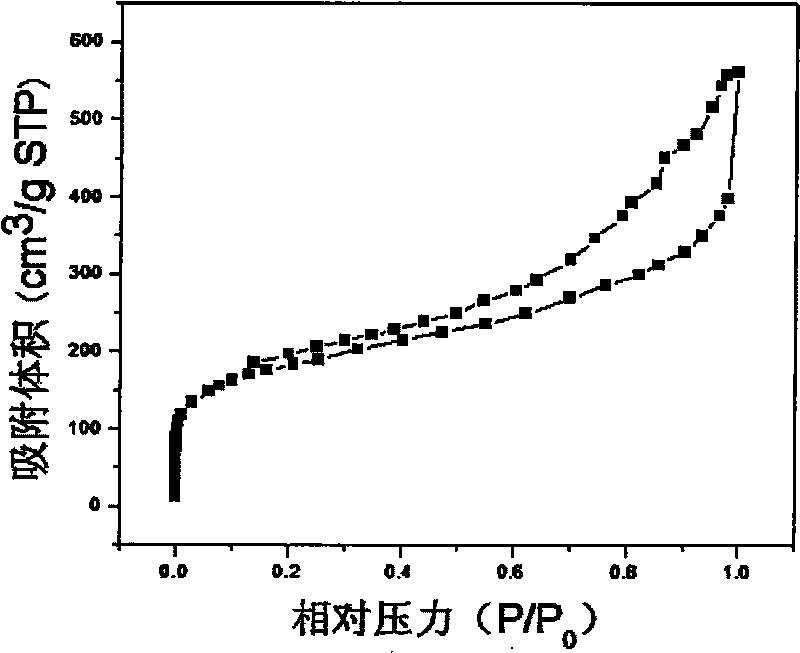

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com