Release paper for artificial leather, preparation method and application thereof

A technology of artificial leather and release paper, applied in papermaking, textiles, papermaking, paper, etc., can solve the problems of complex preparation process and high cost, and achieve the effect of simple production method, low cost and convenient production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

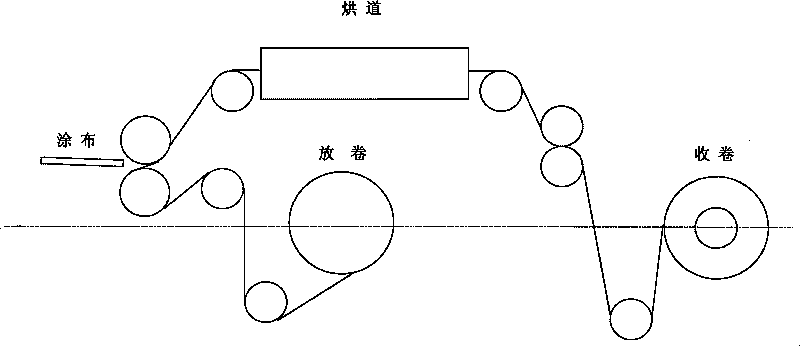

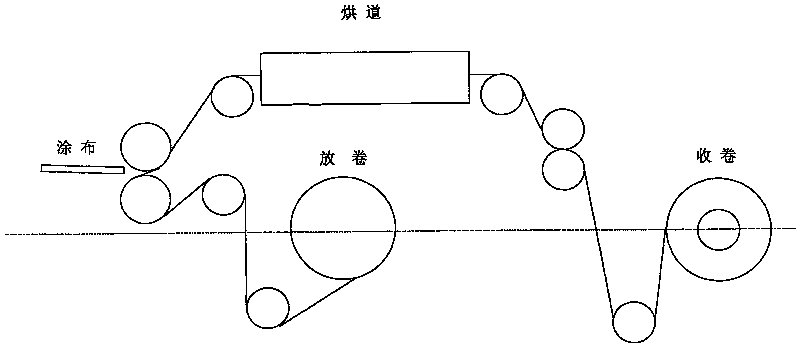

Method used

Image

Examples

Embodiment 1

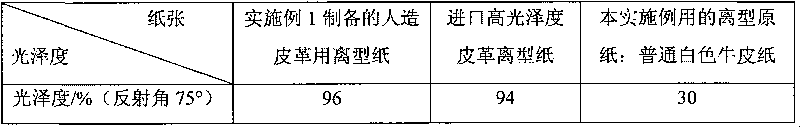

[0051] Preparation of artificial leather release paper with glossiness of 96%

[0052] (1) Preparation of water dispersible polyester

[0053] 25kg neopentyl glycol, 8kg trimethylolpropane, 30kg phthalic anhydride, 6kg adipic acid and 6.9kg xylene were added in a 300-liter stainless steel polymerization reactor with water separator and condenser, The water separator is filled with xylene and protected with nitrogen gas. Raise the temperature to 140°C, at this time most of the solid matter melts, start stirring, then raise the temperature to 160°C for 0.5h, then heat to 180°C to react until the water output reaches 80% of the theoretical amount; then gradually raise the temperature to 230°C, keep the temperature for 3h , when the acid value is 30mgKOH / g, quickly cool to 100°C, add 39.5kg ethylene glycol butyl ether and stir for 15 minutes, cool down to 70°C, add dimethylethanolamine to neutralize to a pH value of 6, react for 0.5h, add deionized water (adjust the solid conten...

Embodiment 2

[0069] Preparation of artificial leather release paper with glossiness of 98%

[0070] (1) Preparation of water-dispersible polymethacrylate

[0071] Add 70.71kg of methyl methacrylate, 14.17kg of butyl acrylate, 8.72kg of methacrylic acid, 3.49kg of N-methylol acrylamide and 2.91kg of β-hydroxyethyl acrylate into the monomer batching tank and mix evenly to obtain Mixture A. Get 1 / 3 of mixture A and add in the 200 liters of stainless steel reactors with reflux condenser that 37.6kg isopropanol is housed, obtain mixture B. Add 0.6kg of azobisisobutyronitrile into the batching tank filled with the remaining 2 / 3 mixture A, stir and mix at room temperature to prepare component C dropwise. The temperature of mixture B was raised to 85°C, and 0.25 kg of azobisisobutyronitrile was added to the reactor, and after stirring for 15 minutes, component C was added dropwise to the reactor for 3 hours. Then add 14.4kg of isopropanol and 0.15kg of azobisisobutyronitrile to the reactor, rai...

Embodiment 3

[0087] Preparation of artificial leather release paper with glossiness of 94%

[0088] (1) Preparation of water-dispersible polymethacrylate

[0089] Add 115kg deionized water, 0.24kg nonylphenol polyoxyethylene ether, 0.29kg sodium lauryl sulfate and 0.20kg sodium bicarbonate into a 500-liter stainless steel reaction kettle with a reflux condenser and two high-position dropping tanks, The mixture A was obtained, and the temperature was raised to 60° C. with stirring. Add 48.3 kg of methyl methacrylate, 31.0 kg of butyl acrylate, 0.94 kg of methacrylic acid and 2.81 kg of β-hydroxyethyl acrylate into a monomer batching tank, stir and mix evenly to obtain mixture B. Add 0.51kg of ammonium persulfate and 20kg of deionized water into another batching tank, stir and mix evenly to obtain mixture C. Add 1 / 10 of the total amount of mixture B and 4kg of mixture C to the reactor containing mixture A, the remaining mixture B is pumped into the high-level dropping tank, and the remaining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com