Soft-measuring method for density in concentration process of salvia miltiorrhiza injection production

A technology of Danshen injection and concentration process, which is applied in neural learning methods, program control, biological neural network models, etc., to achieve good application prospects, strong model interpretation ability, and simple calculation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

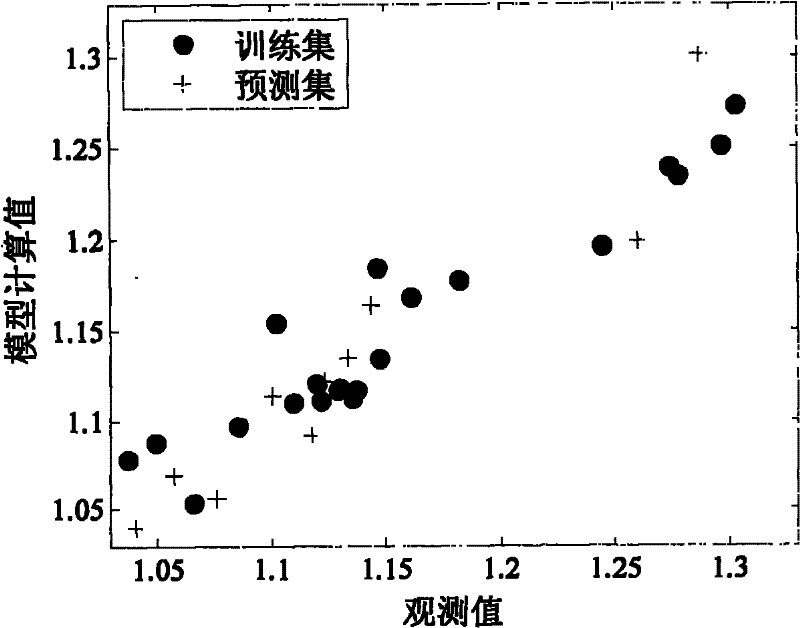

[0031] Embodiment 1: the linear soft sensing method (PLS) of the concentration process density of Danshen injection

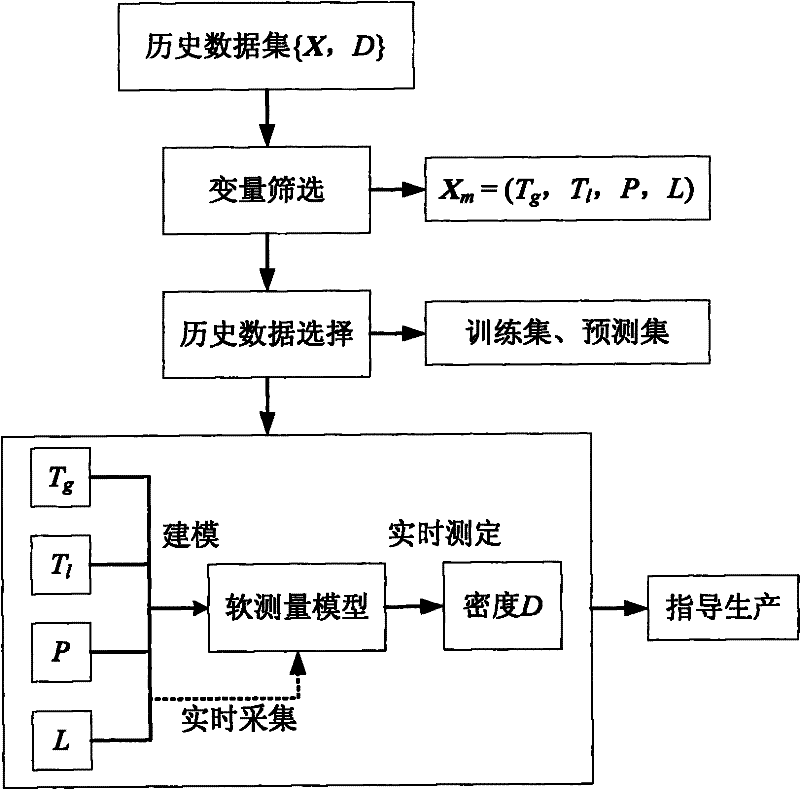

[0032] The principle of the inventive method sees figure 1 .

[0033] The historical data set {X, D} comes from the enrichment section of Danshen injection produced by a pharmaceutical company. Three batches of data are selected, and the number of sampling points in each batch is 60. The selection of samples is evenly distributed throughout the enrichment process. Among them, X is the process variable data that is easily obtained by the sensor in the production line and is relatively accurate, including 9 process variables: heater (X 1 ), Inlet flow rate (X 2 ), cumulative liquid intake (X 3 ), evaporator vacuum (X 4 ), gas phase temperature (X 5 ), liquidus temperature (X 6 ), liquid level (X 7 ), buffer tank pressure (X 8 ) and cooling water flow rate (X 9 ); D is the measured density value of the concentrate, collected using an online density meter....

Embodiment 2

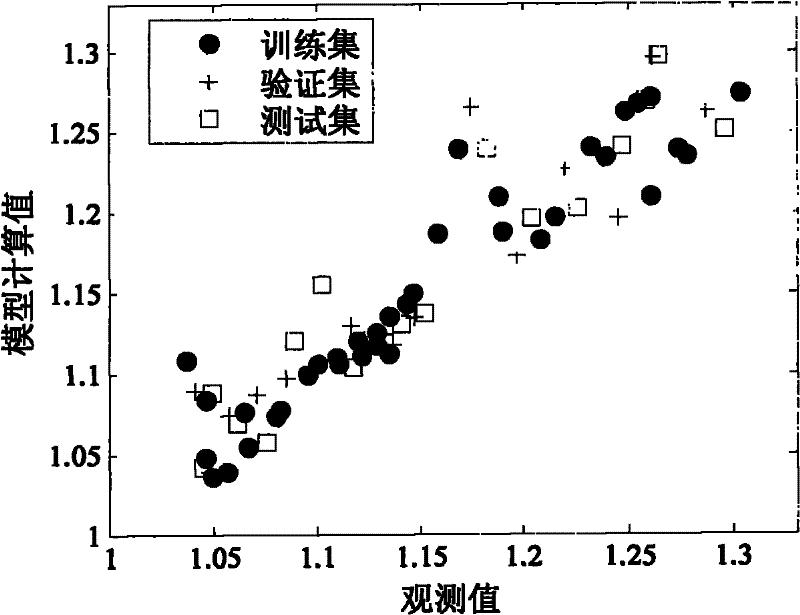

[0048] Embodiment 2: The non-linear soft sensor method (ANN) of the concentration process density of salvia miltiorrhiza injection

[0049] The historical data set {X, D} comes from the enrichment section of Danshen injection produced by a pharmaceutical company. Five batches of data are selected, and the number of sampling points in each batch is 80. The selection of samples is evenly distributed throughout the enrichment process. Among them, X is the process variable data that is easily obtained by the sensor in the production line and is relatively accurate, including 9 process variables: heater (X 1 ), Inlet flow rate (X 2 ), cumulative liquid intake (X 3 ), evaporator vacuum (X 4 ), gas phase temperature (X 5 ), liquidus temperature (X 6 ), liquid level (X 7 ), buffer tank pressure (X 8 ) and cooling water flow rate (X 9 ); D is the measured density value of the concentrate, collected using an online density meter. In order to reduce the systematic error, the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com