Glass fiber reinforced plastic cable channel cover plate and production method thereof

A technology of cable trench cover and glass fiber, applied in artificial islands, underwater structures, buildings, etc., can solve the problems of poor impact resistance, weak bearing capacity, long production cycle, etc., and achieve good insulation performance and fire prevention Flame retardant performance, extended service life, and easy laying and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

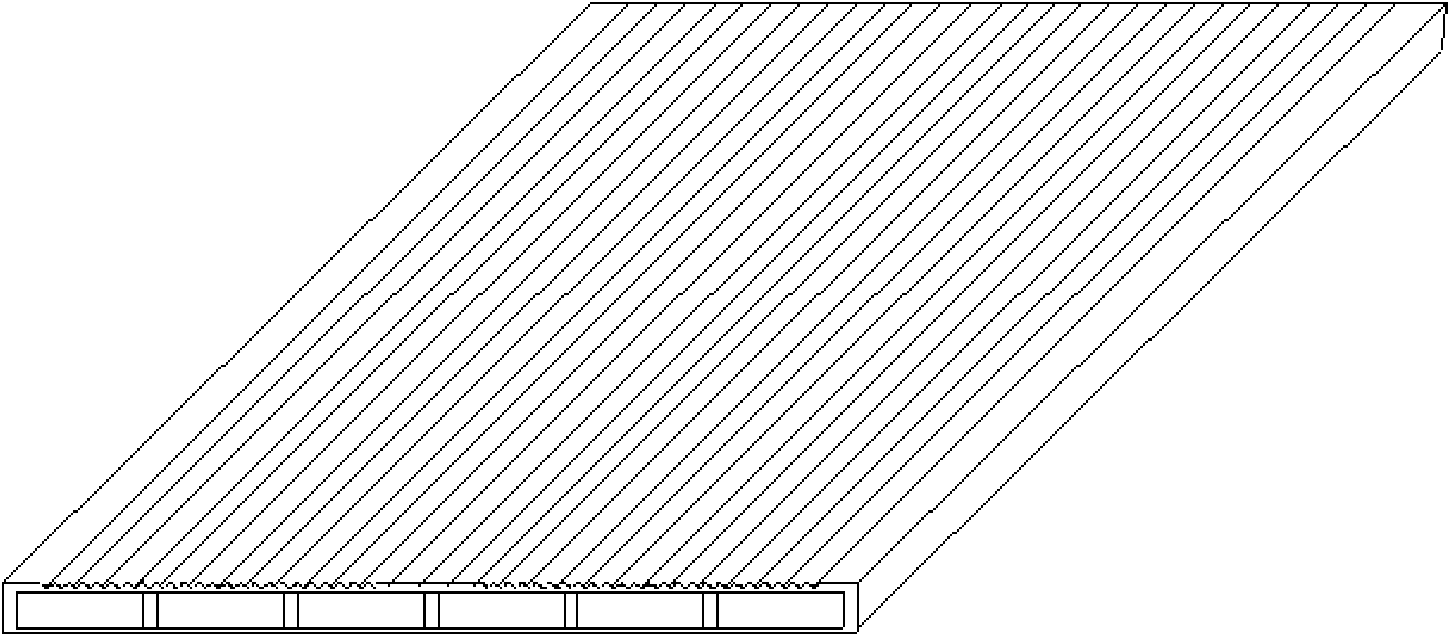

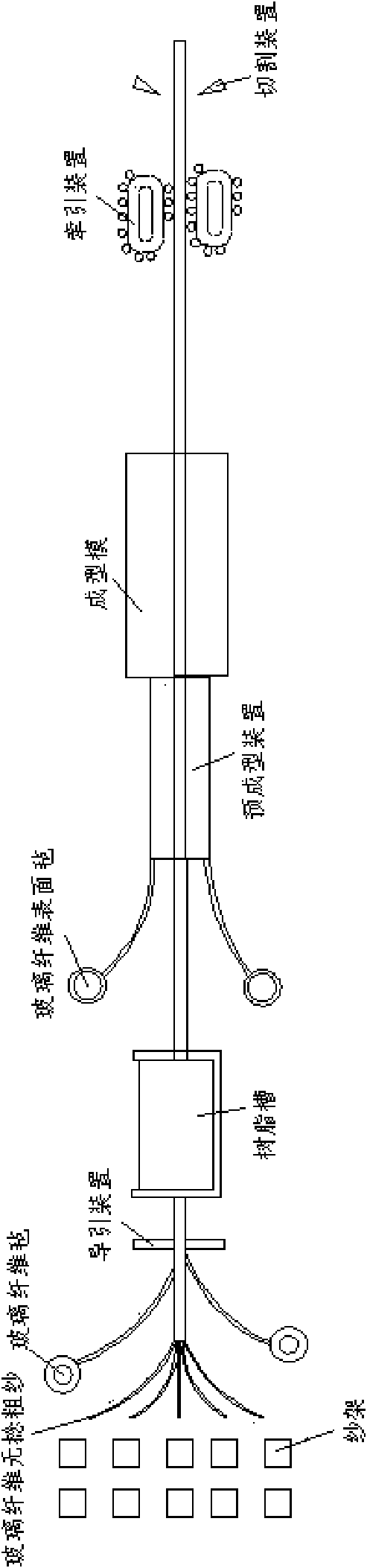

[0023] see figure 1 and figure 2 , a black-gray glass fiber reinforced plastic cable trench cover designed as a cable trench cover with a rectangular hollow structure. There are uniformly distributed longitudinal ribs in the hollow of the cable trench cover. The upper surface of the cable trench cover is provided with various A strip-shaped anti-slip pattern with alternating concavo-convex shapes, and the spacing of the strip-shaped anti-slip patterns is equidistant or unequally spaced;

[0024] The upper surface of the cable trench cover plate in this embodiment is strip-shaped anti-slip lines with alternating concavo-convex and equal intervals.

[0025] The cable trench cover plate is a glass fiber reinforced plastic cable trench cover plate with an integral structure produced by a pultrusion process.

[0026] The weight ratio and production process steps of each raw material of the cable trench cover plate:

[0027] Unsaturated polyester resin 29%

[0028] Dibenzoyl Pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com