Application of Ni-based catalyst in anode of direct borohydride fuel cell

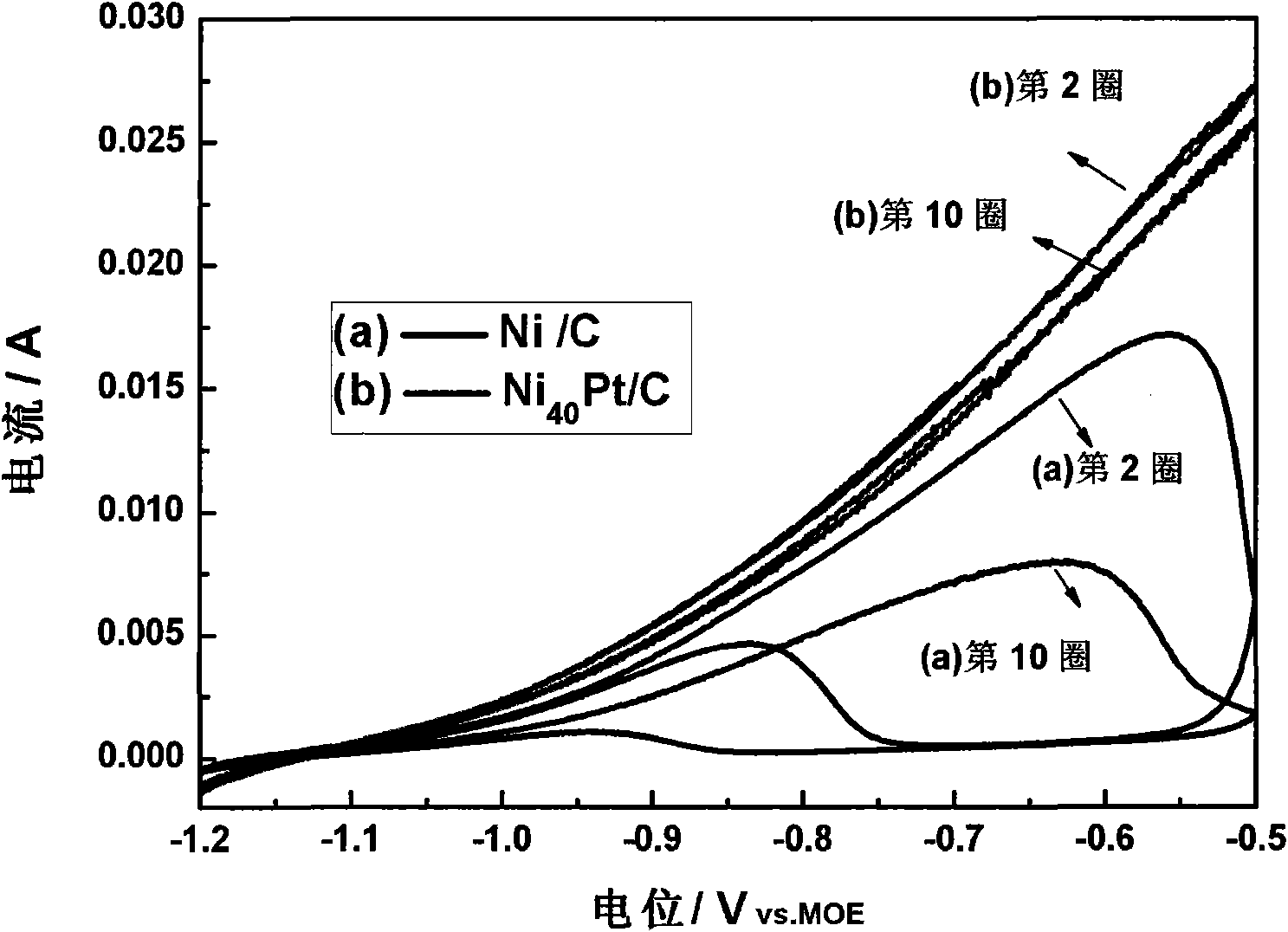

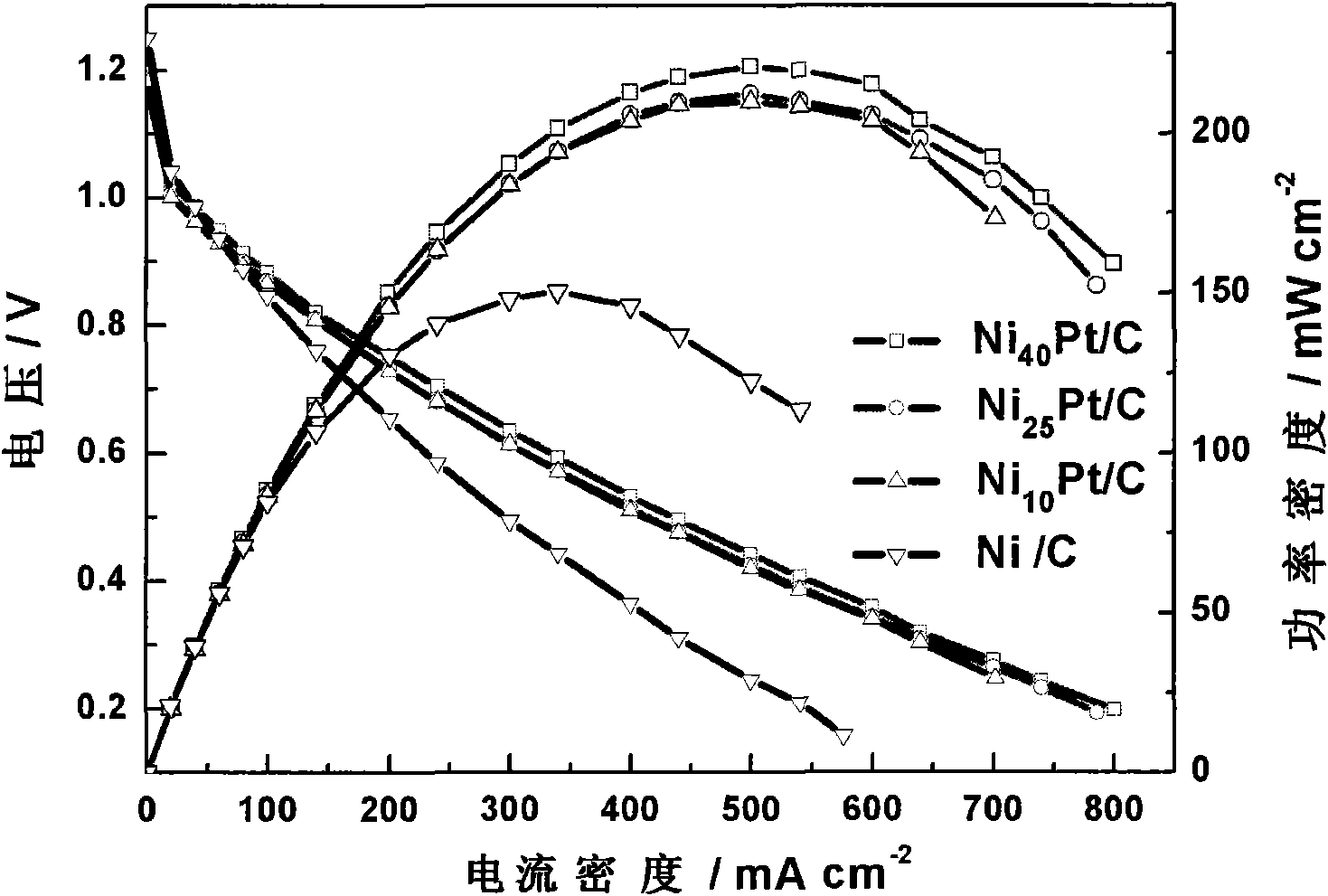

A borohydride and fuel cell technology, which is applied in battery electrodes, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor stability of Ni/C catalysts and low catalyst mass specific activity , Catalyst loading capacity and other problems, to achieve the effect of improving anti-oxidation ability, low loading capacity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

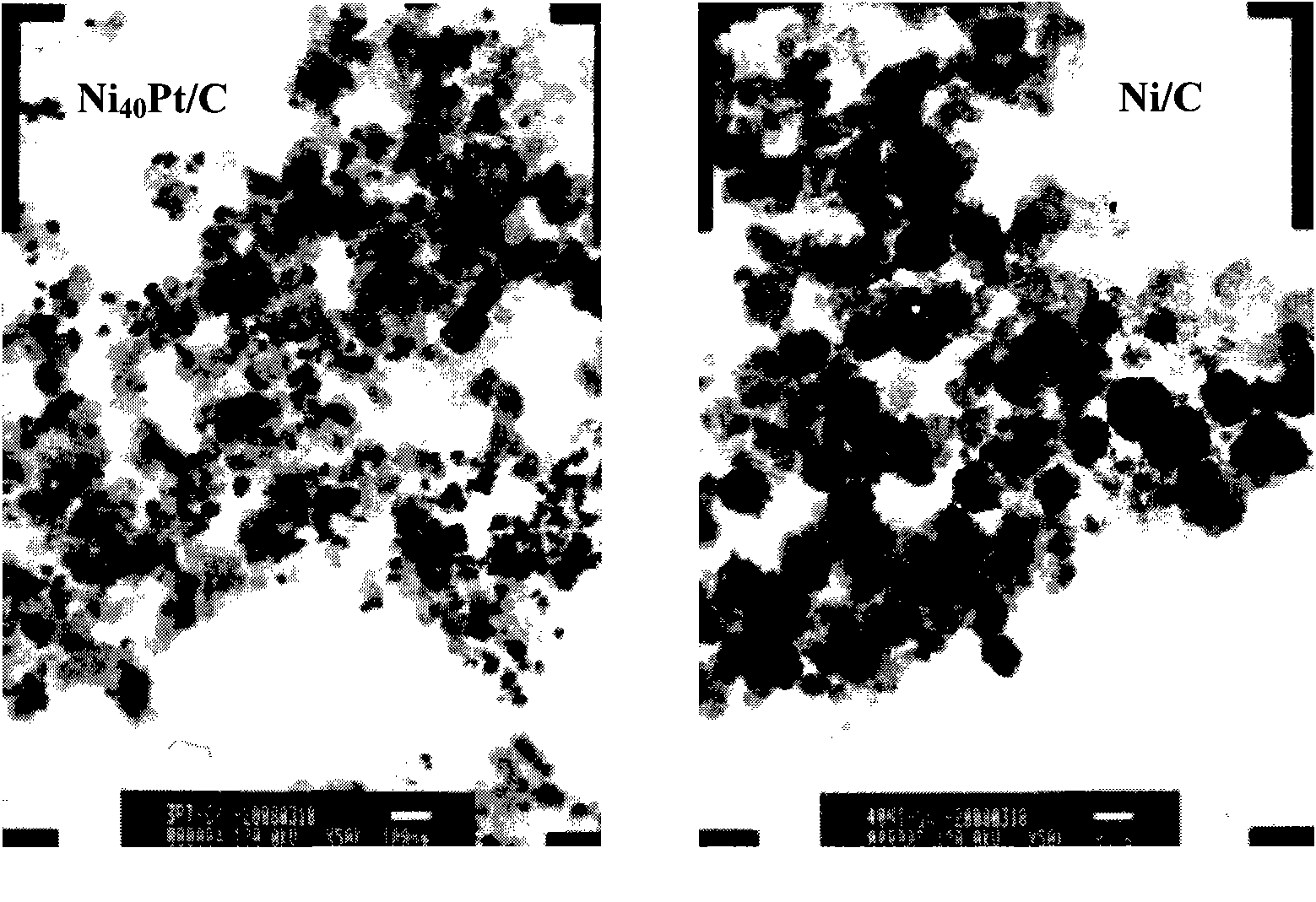

Embodiment 1

[0033] Add 60mg of XC-72 carbon powder into 60ml of ethylene glycol solution, and mix evenly by ultrasonic to obtain slurry A; add 0.31ml of ethylene glycol solution of chloroplatinic acid with a concentration of 10mg Pt / ml, and 3.69ml of ethylene glycol solution with a concentration of 10mg Ni / ml of nickel nitrate ethylene glycol solution, and ultrasonically mixed to obtain a mixed solution B; the above slurry A and solution B were mixed, and 2.0M NaOH ethylene glycol solution was added under stirring conditions to pH = 10.5. Place the above mixture in a water bath at 80°C, add 1.2ml of hydrazine hydrate for reduction under stirring, take it out after 2 hours, leave it overnight, wash with water and filter until neutral and free of Cl - , after drying, a Ni with a total metal content of 40% and a nickel-platinum molar ratio of 40:1 was obtained. 40 Pt / C catalyst.

Embodiment 2

[0035] Add 60mg of XC-72 carbon powder into 60ml of ethylene glycol solution, and mix evenly by ultrasonic to obtain slurry A; add 0.47ml of ethylene glycol solution of chloroplatinic acid with a concentration of 10mg Pt / ml, and 3.53ml of a concentration of 10mg Ni / ml of nickel nitrate ethylene glycol solution, and ultrasonically mixed to obtain a mixed solution B; the above slurry A and solution B were mixed, and 2.0M NaOH ethylene glycol solution was added under stirring conditions to pH = 10.5. Place the above mixture in a water bath at 80°C, add 1.2ml of hydrazine hydrate for reduction under stirring, take it out after 2 hours, leave it overnight, wash with water and filter until neutral and free of Cl - , after drying, a Ni with a total metal content of 40% and a nickel-platinum molar ratio of 25:1 was obtained. 25 Pt / C catalyst.

Embodiment 3

[0037] Add 60mg of XC-72 carbon powder into 60ml of ethylene glycol solution, and mix evenly by ultrasonic to obtain slurry A; add 1.0ml of ethylene glycol solution of chloroplatinic acid with a concentration of 10mg Pt / ml, and 3.0ml of a concentration of 10mg Ni / ml nickel nitrate ethylene glycol solution, and ultrasonically mixed to obtain a mixed solution B; the above slurry A was mixed with solution B, and 2.0M NaOH ethanol solution was added under stirring conditions to pH = 10.5. Place the above mixture in a water bath at 80°C, add 1.2ml of hydrazine hydrate for reduction under stirring, take it out after 2 hours, leave it overnight, wash with water and filter until neutral and free of Cl - , after drying, a Ni with a total metal content of 40% and a nickel-platinum molar ratio of 10:1 was obtained. 10 Pt / C catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com