Preparation method of epoxy resin hollow micropin array

A technology of epoxy resin and microneedle array, applied in the directions of microneedles, chemical instruments and methods, needles, etc., to achieve balanced mechanical properties, easy to ensure work effectiveness, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] like figure 1 and figure 2 Shown, embodiment 2 comprises the following steps:

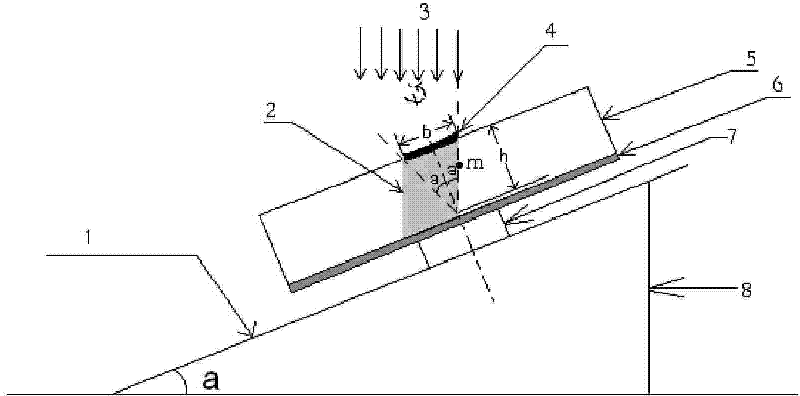

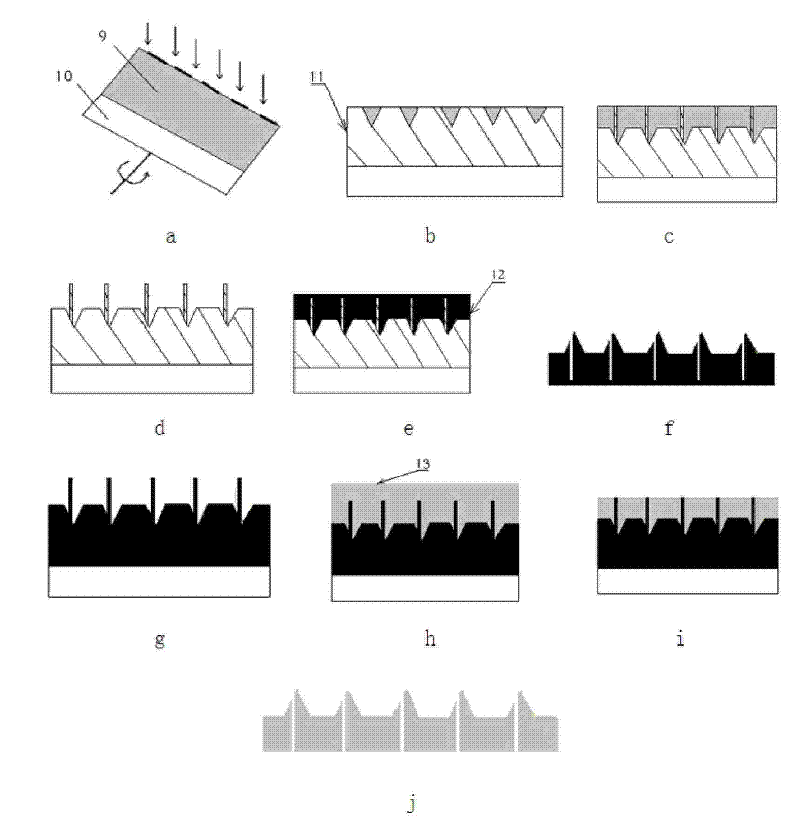

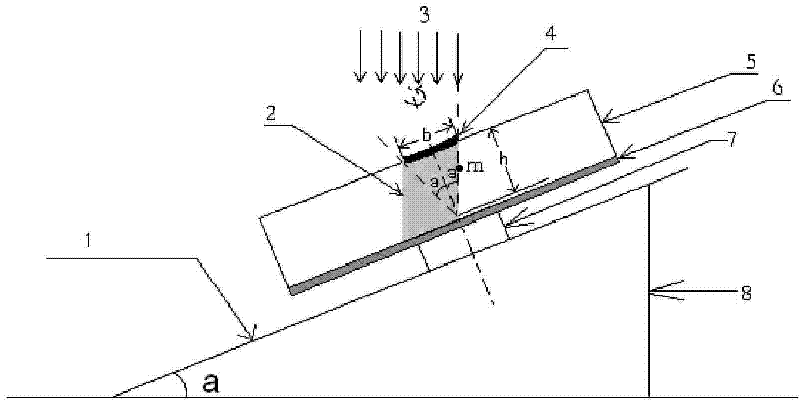

[0047] In the first step, 500 microns of SU8 photoresist was spin-coated on a 1 mm thick glass slide. Set the environment for tilt-rotation exposure: such as figure 1 As shown, adjust the inclination angle of the substrate and the reticle to be 20°, tilt the substrate and the reticle and set the apex angle of the microneedle to be twice the inclination angle of the substrate and the reticle, and then use 3.3mW / cm 2 High-power ultraviolet light, tilt and rotate the exposure for 40 minutes to the substrate and the mask, rotate the substrate and the mask at a speed of 300 rpm while exposing, and make a concave cone structure of SU8 glue, like figure 2 As shown in a, among them: 9 is the SU8 glue that has not been exposed to light, and 10 is the glass substrate. The concave cone structure obtained after tilt-rotation exposure is as follows figure 2 As shown in b, among them: 11 is the S...

Embodiment 3

[0062] like figure 1 and figure 2 Shown, embodiment 3 comprises the following steps:

[0063] In the first step, 500 microns of SU8 photoresist was spin-coated on a 1 mm thick glass slide. Set the environment for tilt-rotation exposure: such as figure 1 As shown, adjust the inclination angle of the substrate and the reticle to be 24°, tilt the substrate and the reticle and set the apex angle of the microneedle to be twice the inclination angle of the substrate and the reticle, and then use 3.6mW / cm 2 High-power ultraviolet light, tilt and rotate the exposure for 30 minutes on the substrate and the reticle, rotate the substrate and the reticle at a speed of 300 rpm while exposing, and make a concave cone structure of SU8 glue, like figure 2 As shown in a, among them: 9 is the SU8 glue that has not been exposed to light, and 10 is the glass substrate. The concave cone structure obtained after tilt-rotation exposure is as follows figure 2 As shown in b, among them: 11 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com