Method for manufacturing novel lining plate

A manufacturing method and lining board technology, which can be used in textiles and papermaking, superstructure sub-assemblies, transport passenger cars, etc., can solve the problems of narrow, difficult, and poor fluidity of glass fiber surface bonding, and achieve improved compactness and uniformity, satisfying mechanical properties, and solving technical bottleneck effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

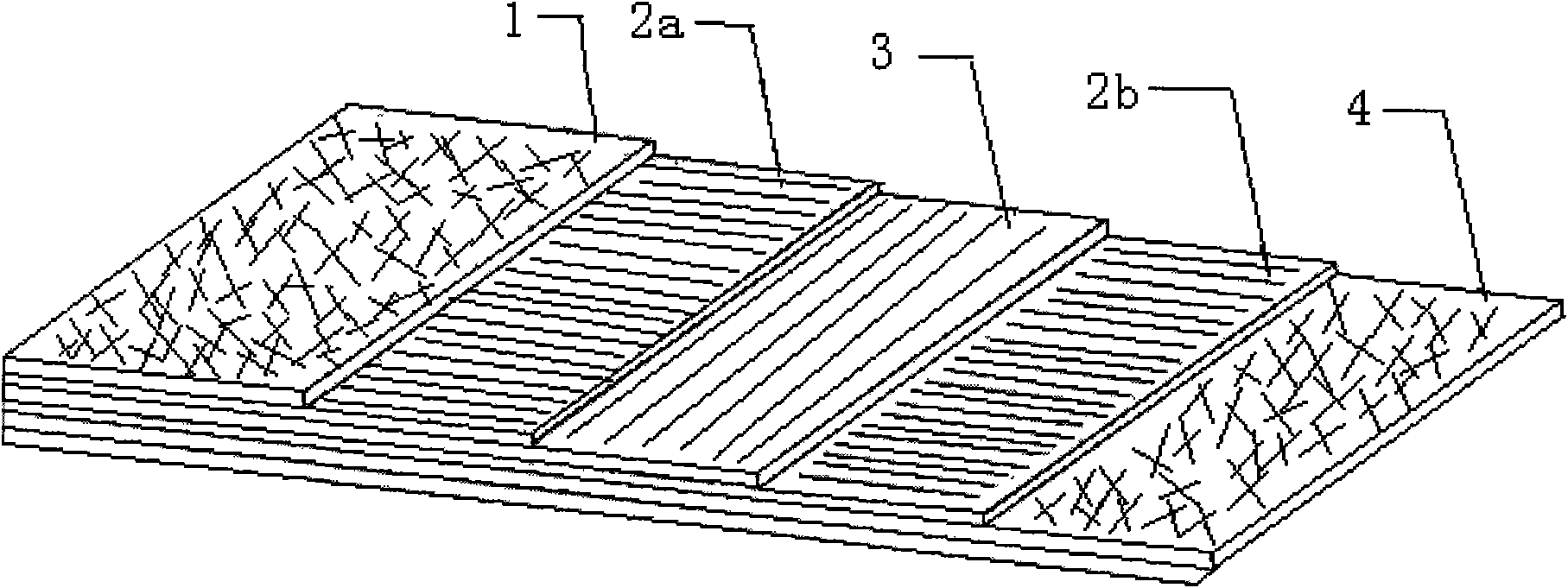

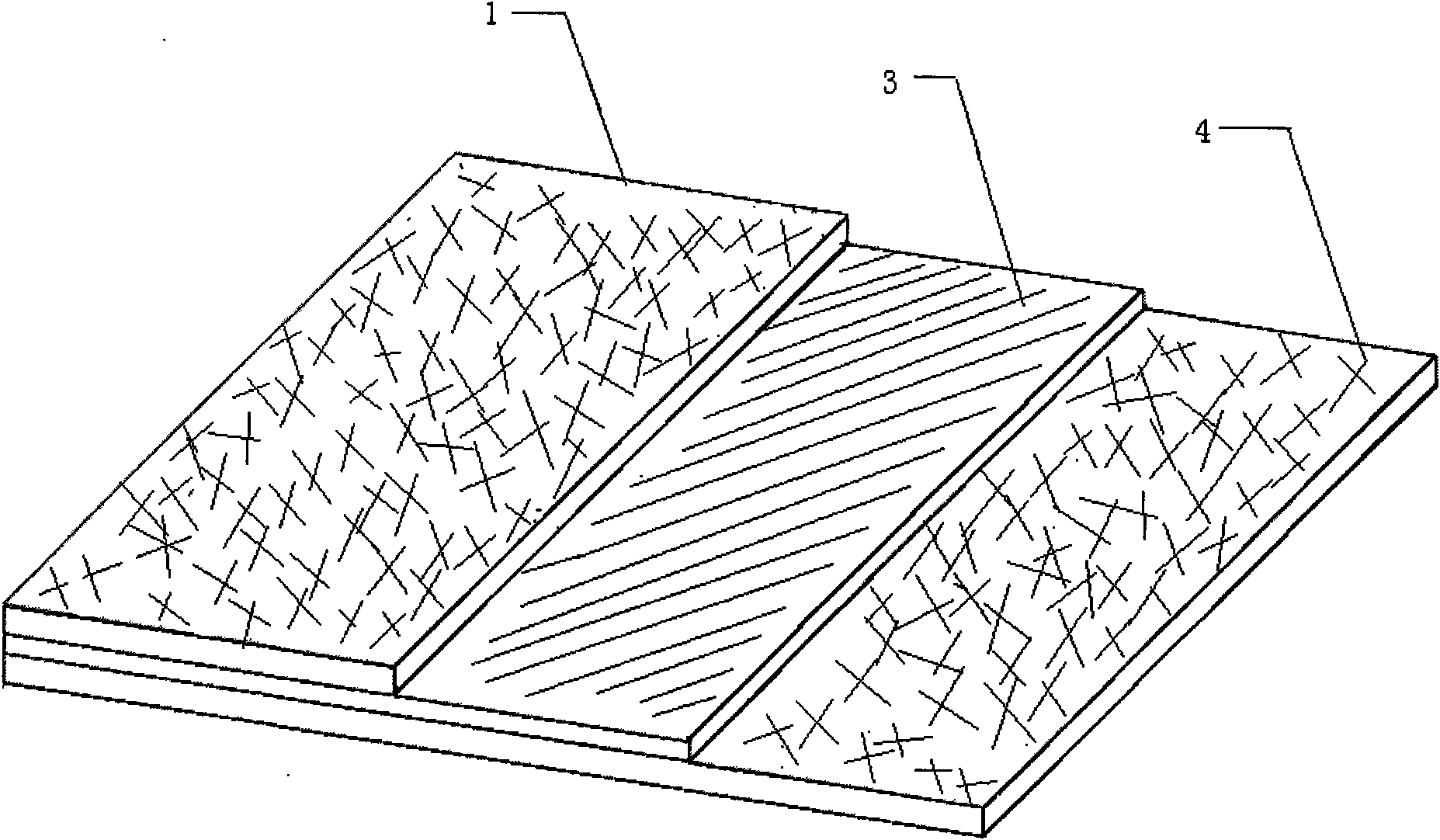

[0032] figure 1 It is a structural schematic diagram of a novel refrigerated container inner liner prepared by the method of the present invention.

[0033] Such as figure 1 Shown: the new refrigerated container inner liner comprises surface layer rough felt 1, middle layer woven felt 2a and 2b, sandwich layer woven felt 3 and bottom layer rough felt 4, which are made by the following method:

Embodiment 1

[0035] Production of refrigerated container liner coils:

[0036] (1) Prepare materials: 50kg of polypropylene fiber filaments, with a single filament diameter of 0.1mm, 100kg of glass fibers, with a single filament diameter of 8μm, 40kg of thermoplastic polypropylene powder, with a particle size of 10μm, and 30kg of polypropylene strong wire;

[0037] (2) Making the surface layer rough felt 1 and the bottom layer rough felt 4: evenly arrange the polypropylene fiber filaments and glass fibers on the creel in a ratio of 2:3 by weight, and use the above-mentioned mixed polypropylene fiber The fiber filaments and glass fibers are continuously thrown into the settling chamber, so that the mixed fibers evenly fall on the forming mesh belt to form the surface layer rough felt 1 and the bottom rough felt 4. The weight of the surface layer rough felt 1 and the bottom rough felt 4 is controlled at 350±50g / m 2 ;

[0038] (3) Make middle layer braided felt 2a, 2b: make middle layer bra...

Embodiment 2

[0047] Production of refrigerated container liner coils:

[0048] (1) Raw materials: 55 kg of polyester fiber filaments, 0.2 mm in diameter of monofilament, 80 kg of glass fiber, 18 μm in diameter of monofilament, 35 kg of thermoplastic polyester powder, 50 μm in particle size, 30 kg of nylon strong wire;

[0049] (2) Making the surface layer rough felt 1 and the bottom layer rough felt 4: evenly arrange the polyester fiber filaments and glass fibers on the creel in a ratio of 3:2 by weight, and use the above-mentioned mixed poly The ester fiber filaments and glass fibers are continuously thrown into the settling chamber, so that the mixed fibers evenly fall on the forming mesh belt to form the surface layer rough felt 1 and the bottom rough felt 4, and the weight control of the surface layer rough felt 1 and the bottom rough felt 4 At 600±50g / m 2 ;

[0050] (3) Make middle layer braided felt 2a, 2b: make middle layer braided felt 2a, 2b together by longitudinal continuous g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com