Aqueous coating substrate treating agent double as primer, surface treatment metallic material and pre-coating metallic material

A metal material and substrate treatment technology, applied in the field of work adhesion and corrosion resistance, which can solve the problems of processing adhesion, insufficient corrosion resistance, insufficient appearance and pollution resistance, and reduce the aesthetics of the coating film, etc. problem, to achieve the effect of saving resources, large industrial value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

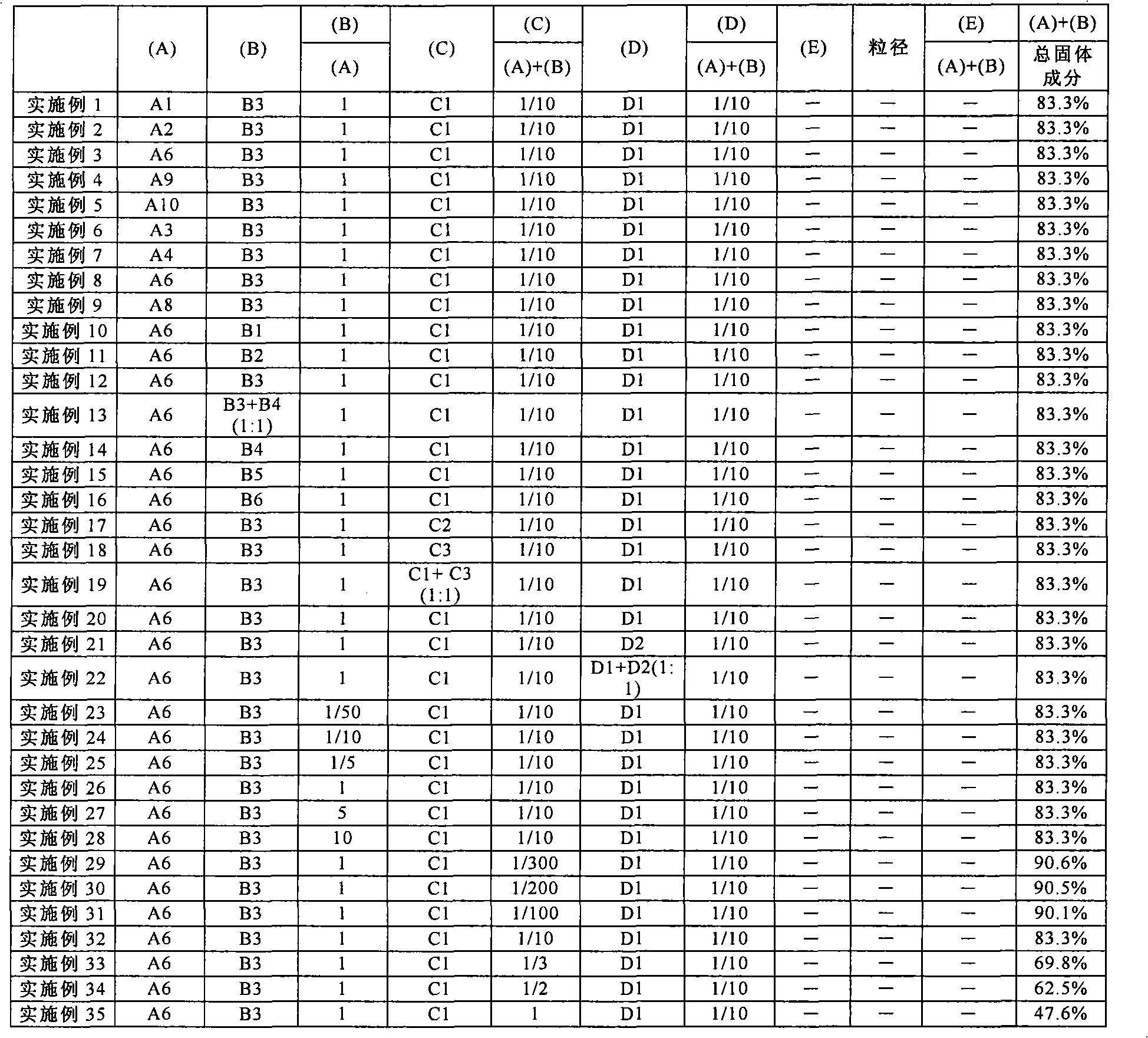

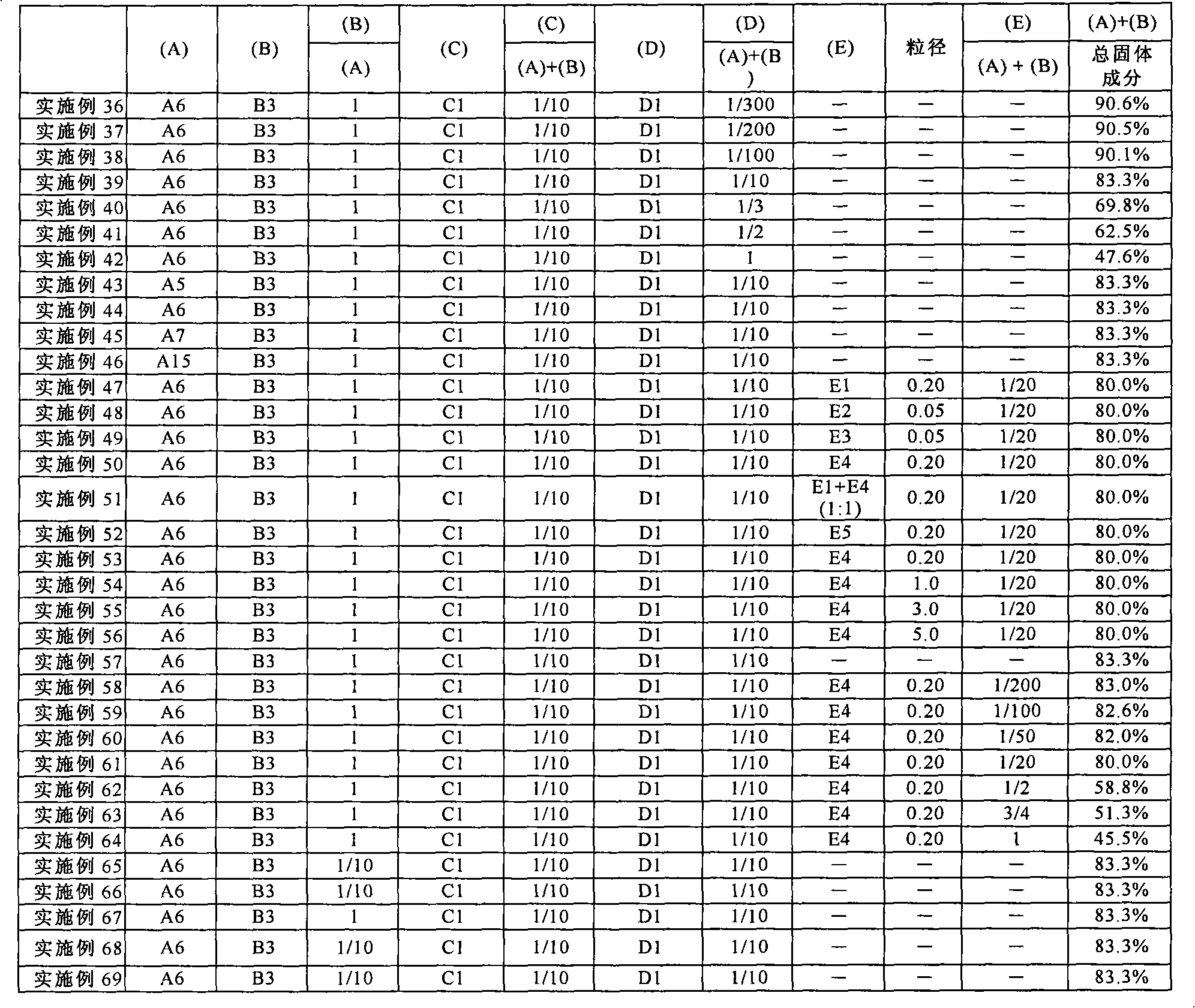

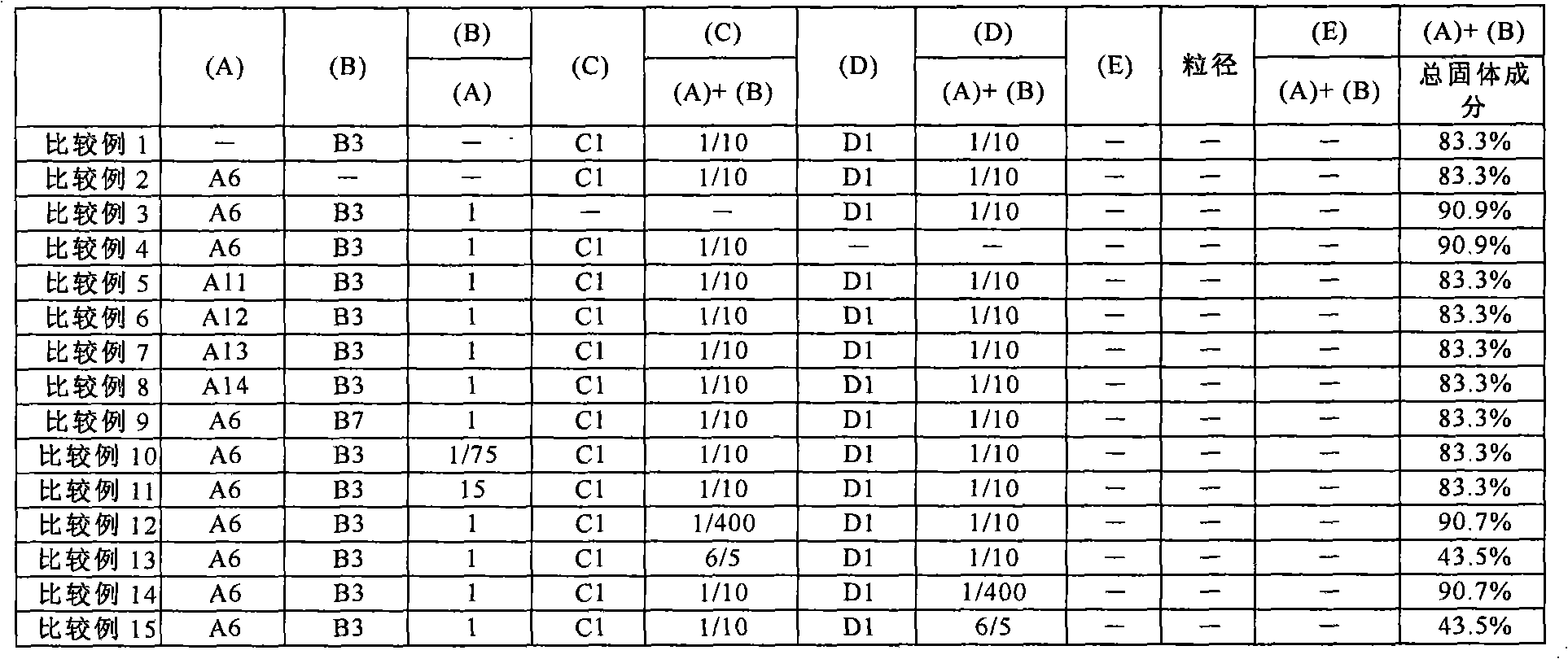

[0096] Hereinafter, the present invention will be specifically described with reference to examples and comparative examples of the present invention, but the present invention is not limited to these examples.

[0097] 1. Preparation of water-based coating base treatment agent

[0098] 1.1 Examples 1-69 and Comparative Examples 1-15

[0099] Mix water-based polyurethane resin (A) or comparative example water-based polyurethane resin, water-based epoxy resin (B) or comparative example water-based epoxy resin, organic compound (C), The joint agent (D) and the microparticles (E) adjusted the solid content concentration to 20% by mass with deionized water to prepare an aqueous coating base treatment agent.

[0100] 1.1.1 Waterborne Polyurethane Resin (A) and Comparative Example Waterborne Polyurethane Resin

[0101] A1 (for example)

[0102] 150 parts by mass of polyester polyol obtained from 1,4-butanediol and adipic acid, 25 parts by mass of 4,4'-dicyclohexylmethane diisocya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com