Environment-friendly polyaniline modified aluminium powder anti-corrosive coating and preparation method thereof

An anti-corrosion coating, polyaniline technology, applied in the field of coatings, can solve problems such as poor anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

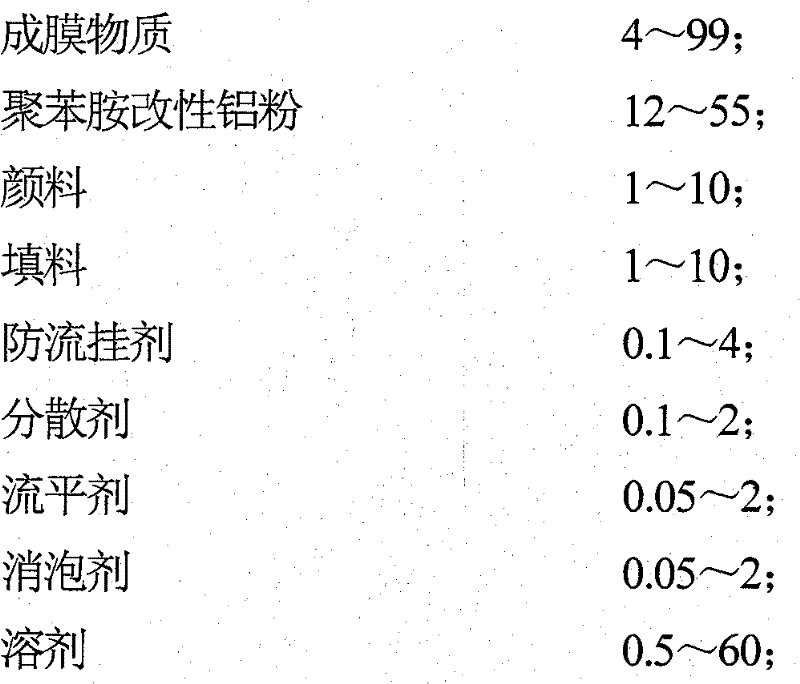

Method used

Image

Examples

Embodiment 1

[0062] Prepare polyaniline modified aluminum powder as follows:

[0063] (a) Prepare a mixed aqueous solution of phosphoric acid and phytic acid: wherein the phosphoric acid is 1.5 mol / liter; the phytic acid is 0.5 mol / liter.

[0064] (b) Add aniline to the mixed aqueous solution of phosphoric acid and phytic acid, the concentration of aniline after mixing is: 0.5 mol / liter. Stirring was continued for 0.5 hours. Take 500ml of mixed aqueous solution of phosphoric acid, phytic acid and aniline, add 70g of 325 mesh aluminum powder, stir for 10 minutes, then pre-cool to 8°C.

[0065] (c) Prepare an aqueous solution of an oxidizing agent: select benzoyl peroxide as an oxidizing agent, and prepare a concentration of benzoyl peroxide of 1.5 mol / liter. Precool the aqueous solution of benzoyl peroxide to 8°C.

[0066] (d) Slowly add 500ml of solution (c) into 500ml of phosphoric acid, phytic acid and aniline mixed aqueous solution (b) containing aluminum powder within 10-30 minutes,...

Embodiment 2

[0070] Put 0.4 parts of dispersant (Disperbyk190), 1.2 parts of leveling agent (Perenol F40), 1.1 parts of defoamer (BYK-066N), 0.5 parts of anti-sagging agent (bentonite), 3 parts of pigment (titanium dioxide), filler ( Barite powder) 2 parts, 25 parts of 325 order polyaniline modified aluminum powders prepared by the method of embodiment 1, join 92 parts of alkyd resins (60% oily linseed oil alkyd resins) and 20 parts of solvents (toluene) , stirred for 20 minutes, and then ground in a sand mill until the fineness was less than 45 microns, and then discharged to make an environmentally friendly polyaniline modified aluminum powder alkyd anti-corrosion coating.

[0071] Spray two coats of this paint on the surface of four 150mm×75mm×2mm No. 45 steel plates that have been conventionally sandblasted to Sa2.5, dry at room temperature for 15 days, and then seal with a 60°C liquid with a weight ratio of rosin: paraffin wax = 1:1. Edge, coating performance test. The dry film thick...

Embodiment 3

[0073] Put 0.7 parts of dispersant (Disperbyk180), 0.8 parts of leveling agent (BYK-359), 0.5 parts of defoamer (Defom5300), 0.6 parts of anti-sagging agent (bentonite), 2 parts of pigment (zinc oxide), filler (talc powder) 2 parts, 25 parts of 325 mesh polyaniline modified aluminum powders prepared by the method of Example 1, join in 50 parts of 2123 model phenolic resins (produced by Shanghai Daowang Adhesive Technology Co., Ltd.) and 20 parts of solvent (toluene) , stirred for 20 minutes, and then ground in a sand mill until the fineness is less than 45 microns, and then discharged to make an environmentally friendly polyaniline modified aluminum powder phenolic anti-corrosion coating.

[0074] Spray two layers of this paint on the surface of four 150mm×75mm×2mm No. 45 steel plates that have been conventionally sandblasted to Sa2.5, dry at room temperature for 15 days, and then seal with a 60°C liquid with a weight ratio of rosin: paraffin = 1:1. Edge, coating performance t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com