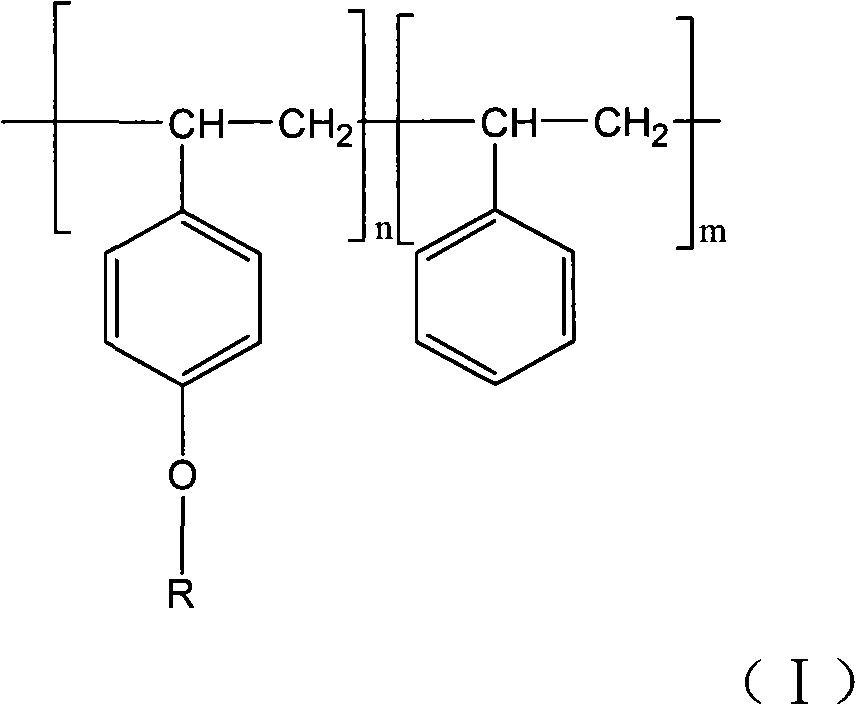

Thermosetting resin composition and prepreg and laminate for printed circuits thereby

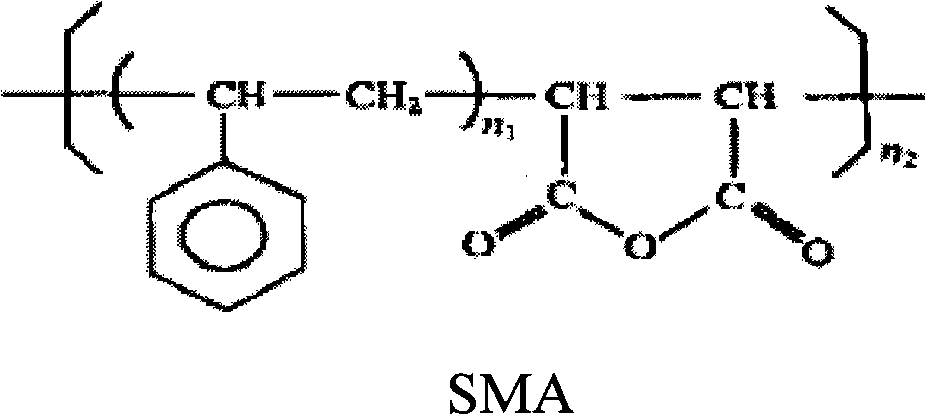

A technology of resin composition and prepreg, which is applied in the direction of circuit substrate materials, printed circuit components, layered products, etc. It can solve the problems of plate layer explosion, limited improvement, and degradation of moisture and heat resistance, and achieve good thermal stability. And heat and humidity resistance, low dielectric loss factor, and the effect of optimizing dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0084] The following examples illustrate various embodiments of the invention. However, these examples do not limit the invention in any way. The specific implementation method is as follows.

Synthetic example 1

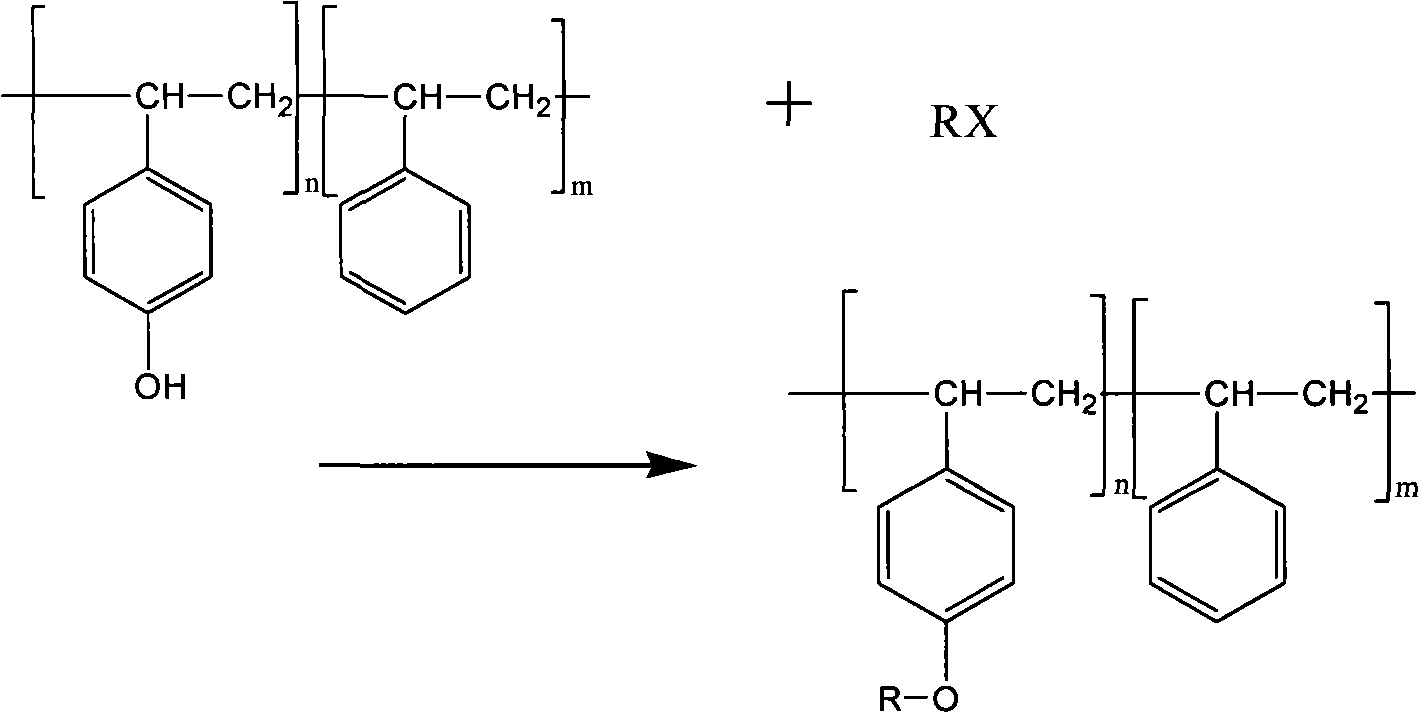

[0086] Mix p-hydroxystyrene / styrene copolymer, epichlorohydrin and dioxane, and feed the p-hydroxystyrene / styrene copolymer and epichlorohydrin at a molar ratio of 1:5. Dioxane has a p-hydroxystyrene / styrene copolymer weight ratio of 1.89. p-Hydroxystyrene / styrene copolymer synthesized by known method, Wn is 4300. Above-mentioned mixture is heated under nitrogen protection, and heating temperature is at 80 degree, and constantly stirs, and dropwise adds sodium hydroxide solution simultaneously, the concentration of used sodium hydroxide solution is 25wt%, sodium hydroxide and p-hydroxystyrene / styrene copolymer The molar ratio of the lye is 2 / 1, and the lye is added dropwise within 3 hours. During the reaction process, the moisture and epichlorohydrin in the system are continuously separated from the system by azeotropic, and the stratified epichlorohydrin returns to the system. Excess epichlorohydrin and dioxane were distilled off under reduced pressure, methyl isobutyl keton...

Synthetic example 2

[0088] Mix p-hydroxystyrene / styrene copolymer, epichlorohydrin and toluene, and feed the p-hydroxystyrene / styrene copolymer and epichlorohydrin at a molar ratio of 1:10. Dioxane has a p-hydroxystyrene / styrene copolymer weight ratio of 1.89. p-Hydroxystyrene / styrene copolymer synthesized by known method, Wn is 30000. Above-mentioned mixture is heated under the protection of nitrogen, heating temperature is at 100 degree, and constantly stirs, dropwise adds sodium hydroxide solution simultaneously, the concentration of used sodium hydroxide solution is 25wt%, sodium hydroxide and p-hydroxystyrene / styrene copolymer The molar ratio of the lye is 2 / 1, and the lye is added dropwise within 2 hours. During the reaction, the moisture and epichlorohydrin in the system are continuously separated from the system by azeotropy, and the stratified epichlorohydrin returns to the system. Excess epichlorohydrin and toluene were distilled off under reduced pressure, methyl isobutyl ketone was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com