Polysilicon nanometer film pressure sensor with temperature sensor and manufacture method thereof

A pressure sensor and temperature sensor technology, applied in nanostructure manufacturing, fluid pressure measurement by changing ohmic resistance, thermometers, etc., can solve the problem that high sensitivity and low temperature coefficient cannot be obtained at the same time, and high sensitivity and low temperature coefficient cannot be obtained at the same time etc. to achieve high sensitivity, lower cost, and smaller chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

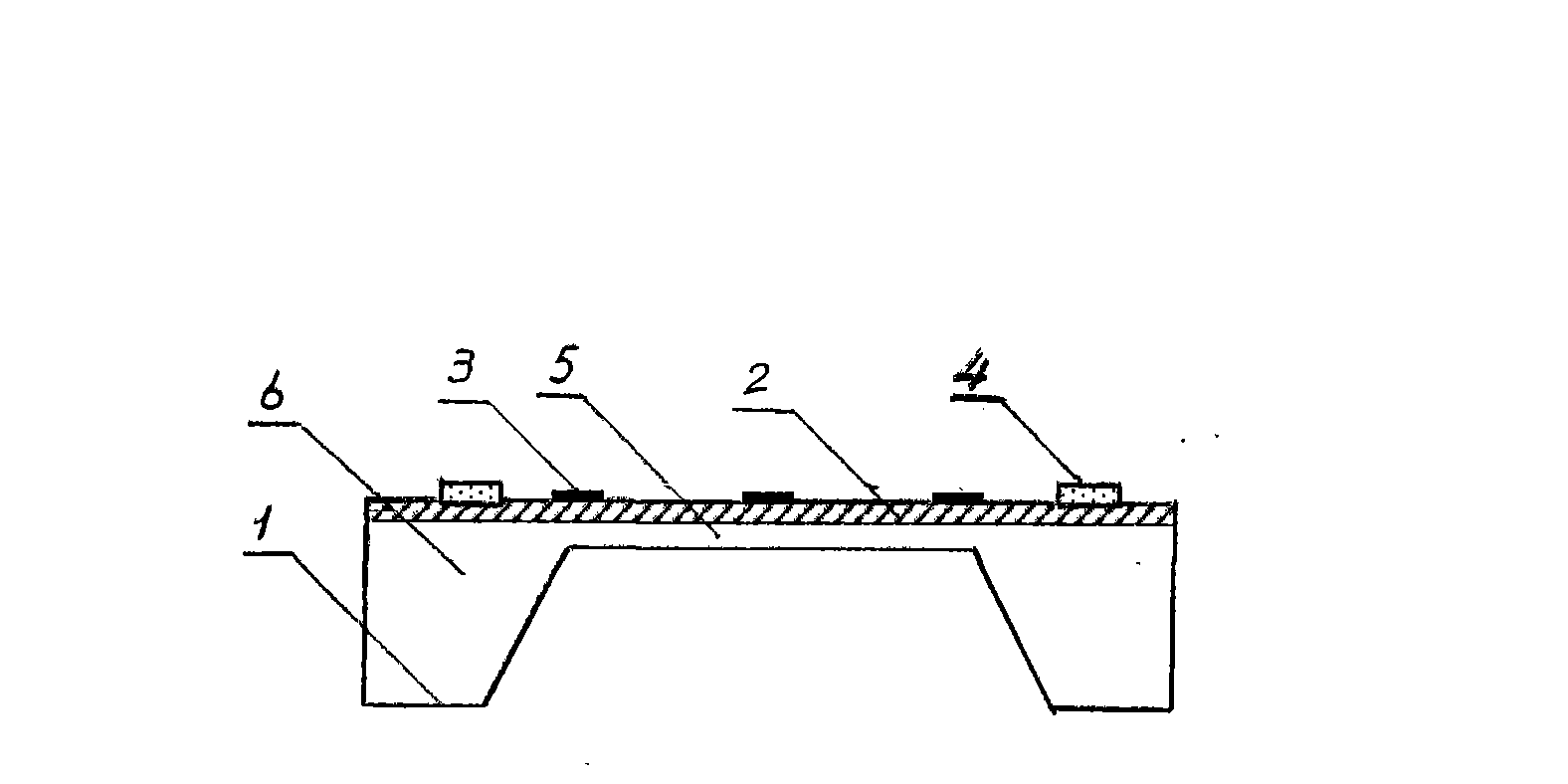

[0012] Example 1: Combining figure 1 , the present invention is a polysilicon nano-membrane pressure sensor with a temperature sensor, which is composed of a monocrystalline silicon silicon cup (1), an insulating layer (2), a polysilicon nano-membrane piezoresistor (3) and a thin film resistor (4) , the monocrystalline silicon silicon cup (1) is connected with the insulating layer (2), and the insulating layer (2) is connected with the polycrystalline silicon nano-film piezoresistor (3) and the thin film resistor (4).

[0013] The monocrystalline silicon silicon cup (1) includes a pressure-sensitive film (5) and a peripheral fixed support structure (6), the pressure-sensitive film (5) is located on the upper part of the monocrystalline silicon silicon cup (1), and the peripheral fixed support structure (6) ) are located on both sides of the monocrystalline silicon silicon cup (1).

[0014] The manufacturing method of the polysilicon nano-membrane pressure sensor with temperat...

Embodiment 2

[0015] Example 2: Combining figure 1 , the working principle of the present invention mainly contains the following two aspects:

[0016] 1. Connect polysilicon nanofilm varistors into a Wheatstone bridge. Changes in external pressure will lead to changes in the resistance of the varistors, which will lead to changes in the output signal of the bridge. The pressure can be measured by measuring the output signal of the bridge. Measurement;

[0017] 2. The resistance value of the thin film resistor changes with the temperature, and the temperature measurement is realized by measuring the resistance value of the thin film resistor.

Embodiment 3

[0018] Embodiment 3: the polysilicon nano-membrane pressure sensor manufacturing method with temperature sensor of the present invention, described thin-film resistance is as the temperature measurement unit of sensor, is example with aluminum thin-film resistance, and its process step is as follows:

[0019] 1. Select a 4-inch 400μm thick N-type (100) double-sided polished single crystal silicon wafer with a resistivity of 2-4Ωcm;

[0020] 2. After the silicon wafer is cleaned, the silicon dioxide insulating layer is grown by high temperature thermal oxidation;

[0021] 3. Use LPCVD technology to deposit polysilicon nano-film on the front side of the silicon wafer, the deposition temperature is 620°C, and the thickness is 80-90nm;

[0022] 4. Use ion implantation technology to do boron doping on the polysilicon nanofilm, and then anneal for 30 minutes in a nitrogen atmosphere at 1100°C;

[0023] 5. Photolithographic polysilicon nano-film varistor;

[0024] 6. Use a vacuum c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com