Method for recovering and utilizing kiln slag of zinc hydrometallurgy volatilizing kiln

A technology of hydrometallurgy and kiln slag, which is applied in the direction of wet separation, chemical instruments and methods, and filtration and sieving, can solve the problems that it is difficult to obtain pure or grade-enriched products, and achieve environmental pressure reduction, effective utilization, and The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] The specific composition of the kiln slag sample used is: iron 35.14%, copper 1.03%, zinc 5.03%, gallium 194g / ton, indium 154g / ton, germanium 20g / ton, silver 160g / ton, sulfur 5.13% , silicon oxide 20.24%, carbon 14%. Phase analysis shows that the iron in the kiln slag is mainly metallic iron, followed by ferrous oxide and ferrous sulfide; the copper in the kiln slag is mainly metallic copper and copper sulfide.

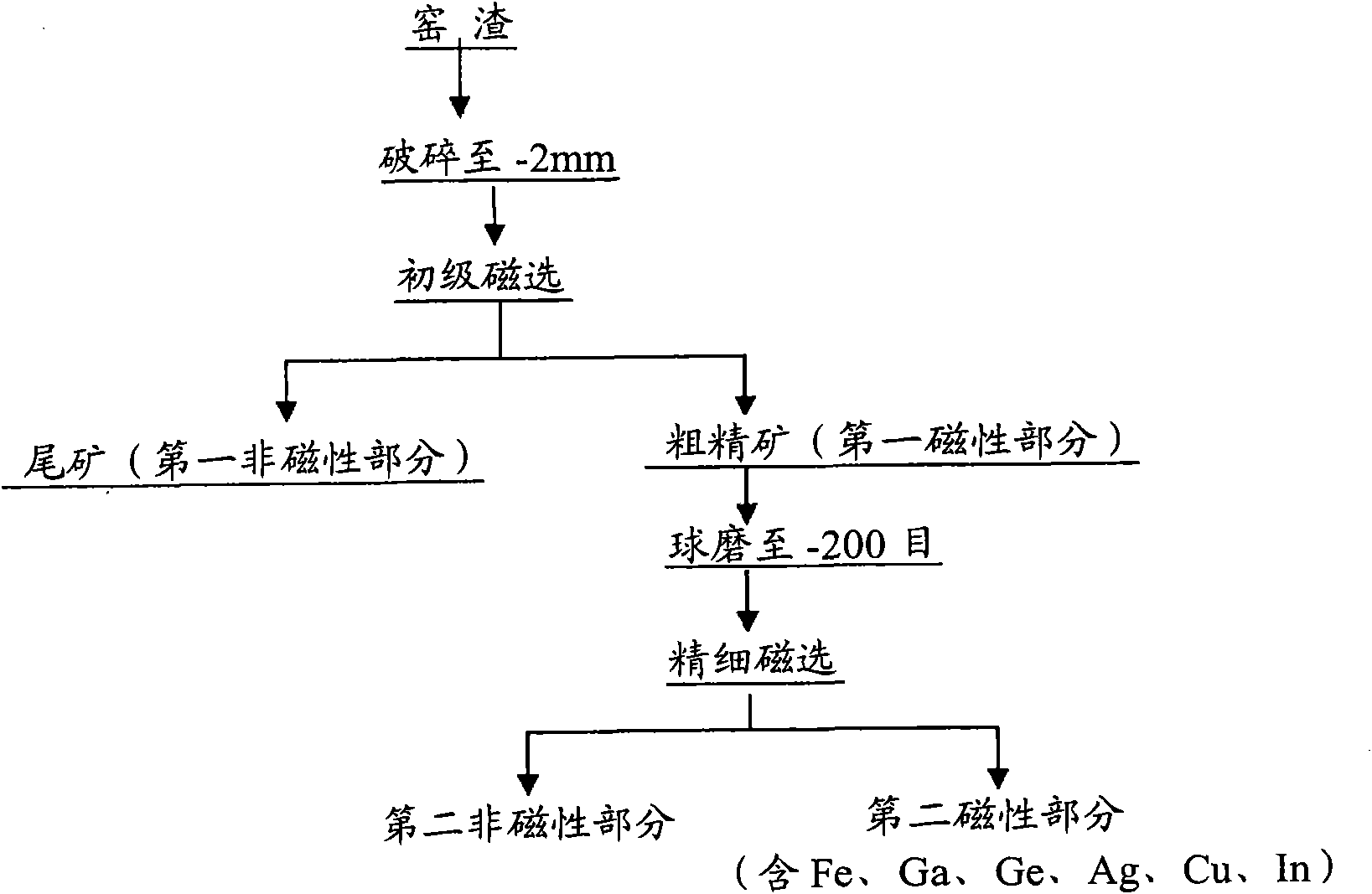

[0109] As shown in Figure 1, the kiln slag is crushed into a particle size of about 2mm with a jaw crusher, and the magnetic separator is used for primary separation, and the field strength adopted is 1500 Oersted to obtain the first non-magnetic part (tailings) I) and the first magnetic fraction (coarse concentrate I). Then ball mill the coarse ore I to a fineness of about 200 meshes, and use a weak magnetic separator to carry out dry concentration under a field strength of 600 Oersted to obtain the second non-magnetic part (tailings II) and the second magnet...

Embodiment 2

[0111] The specific composition of the kiln slag sample used is: iron 35.14%, copper 1.03%, zinc 5.03%, gallium 194g / ton, indium 154g / ton, germanium 20g / ton, silver 160g / ton, sulfur 5.13% , silicon oxide 20.24%, carbon 14%. Phase analysis shows that the iron in the kiln slag is mainly metallic iron, followed by ferrous oxide and ferrous sulfide; the copper in the kiln slag is mainly metallic copper and copper sulfide.

[0112] As shown in Figure 1, the kiln slag is crushed into a particle size of about 2mm with a jaw crusher, and the magnetic separator is used for primary separation, and the field strength adopted is 1500 Oersted to obtain the first non-magnetic part (tailings) I') and the first magnetic fraction (coarse concentrate I'). Then ball mill the coarse concentrate I' to a fineness of about 200, and use a weak magnetic separator to carry out wet concentration under a field strength of 600 Oersted to obtain the second non-magnetic part (tailings II') and the second m...

Embodiment 3

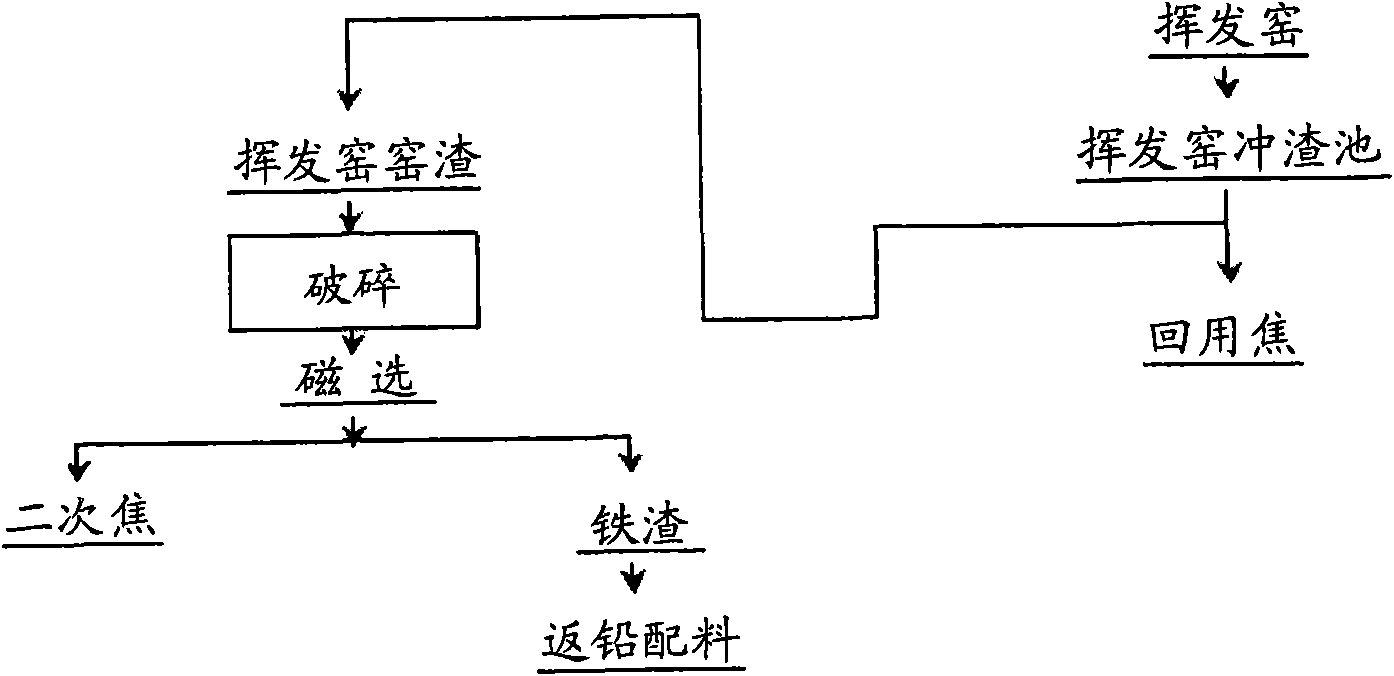

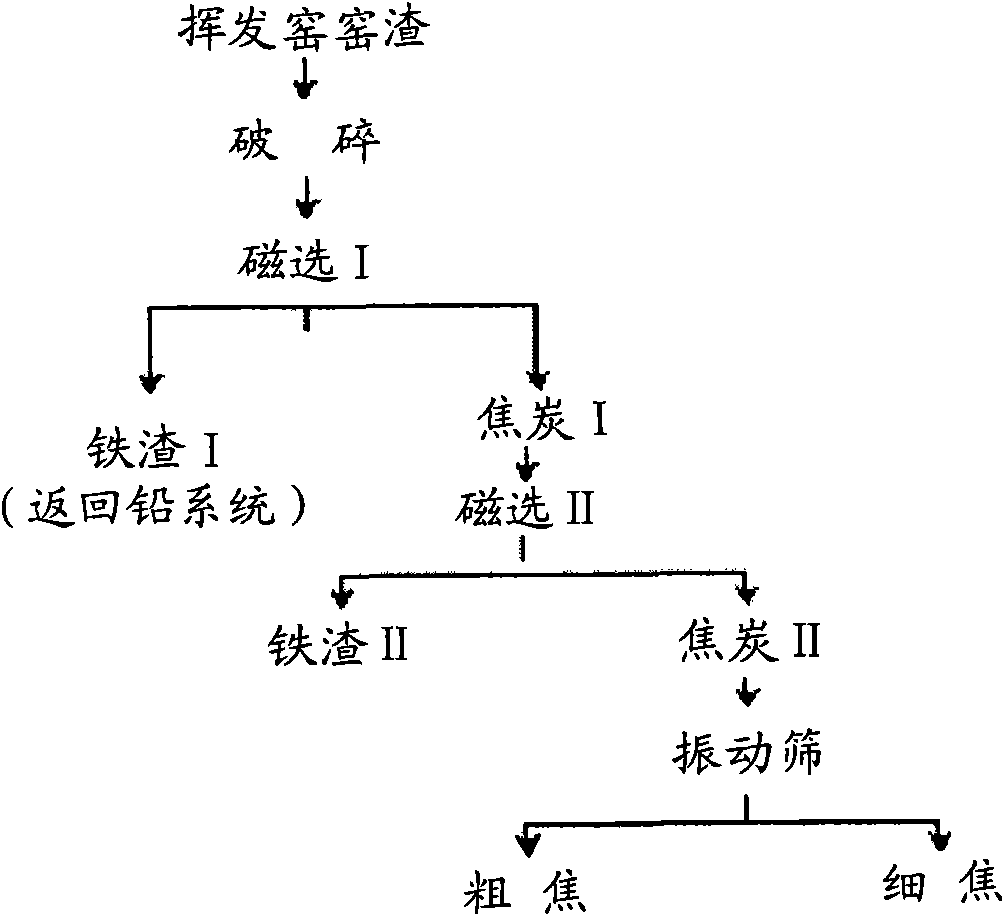

[0118] As shown in Figure 2, the kiln slag from the volatilization kiln undergoes hydraulic washing in the slag washing pool, and after separating part of the coke powder (recycled coke), the kiln slag is crushed and ground into a kiln slag with a particle size of less than 2mm, which is then dried with a dry A type magnetic separator is used for magnetic separation, and its magnetic field strength is 800-1800 Oersted, most preferably 1000 Oersted, to obtain secondary coke and iron slag. Iron slag can be used as a lead-returning ingredient. The results are shown in Table 11. The yield of the magnetic part (iron slag) is 60%, the iron grade can be increased to 60.21%, and the carbon can be reduced to 2.36%; a large amount of carbon, silicon, magnesium, calcium, aluminum, etc. are enriched in the non-magnetic part of the secondary coke , the yield is 40%, the carbon recovery rate is 87.7%, and its carbon content is 25%.

[0119] Table 11 Example 3 test results

[0120]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com