Method for removing diamond-like carbon film on steel surface

A steel surface and diamond technology, which is applied in the field of removing the coating on the surface of the workpiece, can solve the problems of low precision of the mechanical grinding removal method, unfavorable large-scale promotion and use, and easy damage to the workpiece substrate, etc., to achieve good conductivity and good corrosion inhibition The effect of slowing down the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

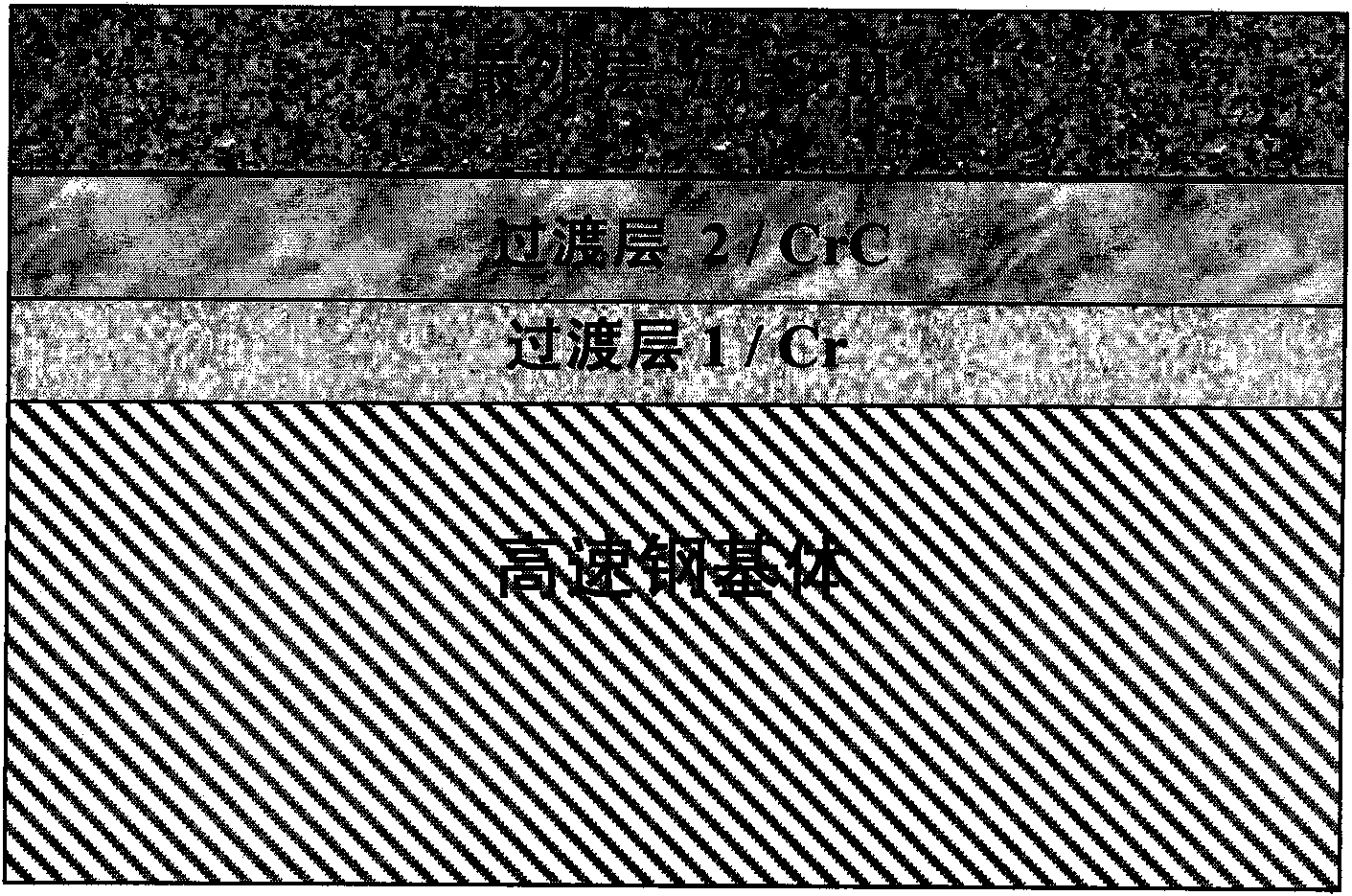

[0020] The workpiece to be processed is a high-speed steel twist drill, the surface is a multi-layer film structure, and the order from bottom to top is chromium / chromium carbide / a-C:H (including similar Ti / TiC / a-C:H, W / WC / a-C: H), the structure of the film on the surface of the workpiece is shown in figure 1 shown. Removing the multilayer film on its surface includes the following steps:

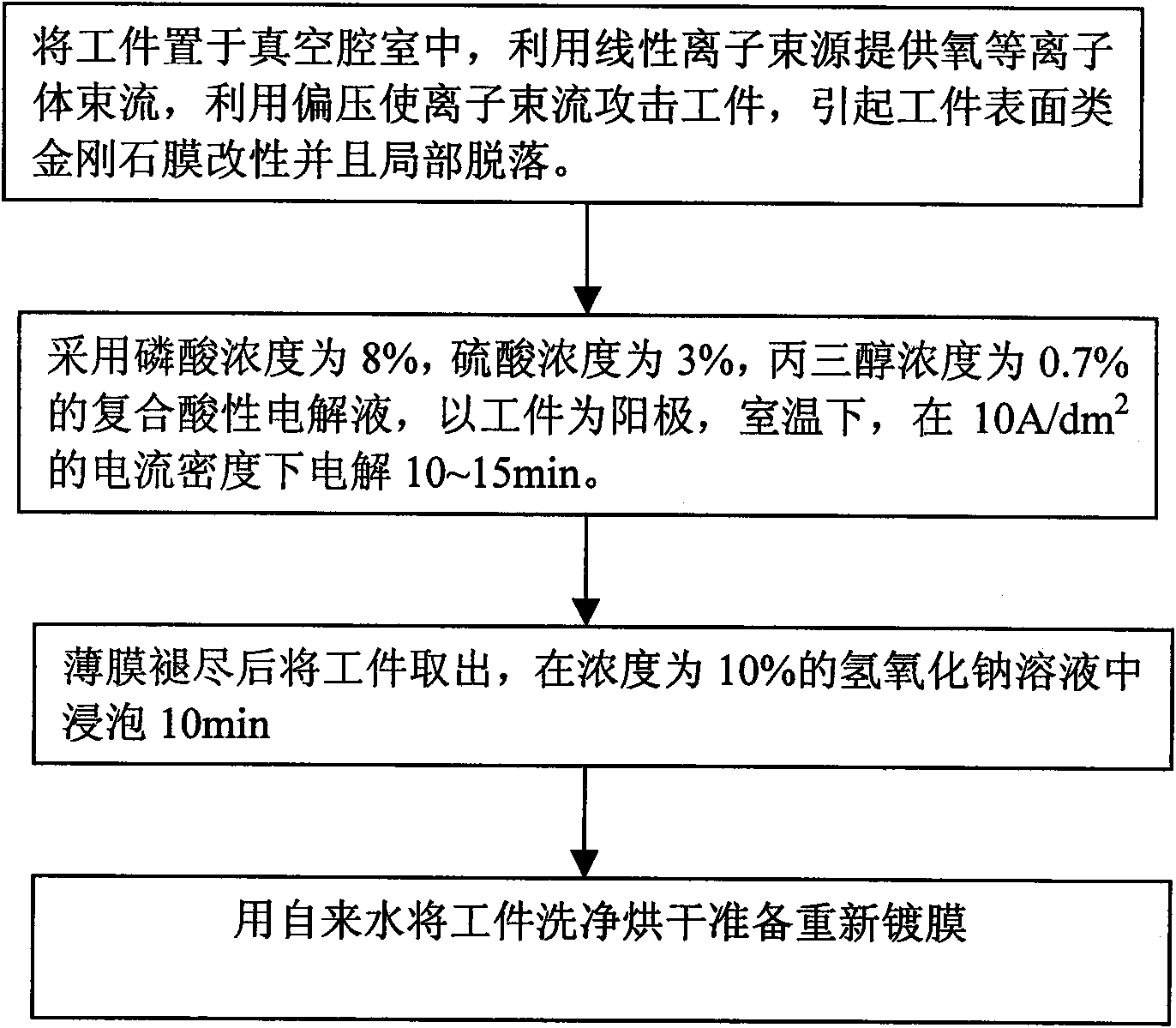

[0021] ① Place the workpiece in a vacuum chamber, use a linear ion beam source to provide an oxygen plasma beam, and accelerate the ion beam to attack the workpiece under a certain bias voltage, causing the diamond-like film on the surface of the workpiece to be modified and partially peeled off.

[0022] ②The volume concentration of phosphoric acid is 5%-10%, the volume concentration of sulfuric acid is 1%-5%, and the volume concentration of glycerol is 0.1%-2%. Preferably, the volume concentration of phosphoric acid is 8%, and the volume concentration of sulfuric acid is Concentration o...

Embodiment 2

[0026] The workpiece to be processed is a carbon steel sewing machine needle bar part, the surface is a multi-layer film structure, and it is Cr / CrC / a-C:H from bottom to top (including similar Ti / TiC / a-C:H, W / WC / a-C:H). Removing the multilayer film on its surface includes the following steps:

[0027] ① Place the workpiece in a vacuum chamber, use a linear ion beam source to provide an oxygen plasma beam, and accelerate the ion beam to attack the workpiece under a certain bias voltage, causing the diamond-like film on the surface of the workpiece to be modified and partially peeled off.

[0028] ②The volume concentration of phosphoric acid is 7%-12%, the volume concentration of sulfuric acid is 0.5%-3%, and the volume concentration of glycerol is 0.1%-3%. Preferably, the volume concentration of phosphoric acid is 9%, and the volume concentration of sulfuric acid is 9%. Concentration of 2%, glycerol volume concentration of 1% composite acidic electrolyte, with the workpiece a...

Embodiment 3

[0032] The workpiece to be treated is a stainless steel mobile phone shell, the surface of which is coated with a-C:H single-layer film. Removing its surface diamond-like carbon film comprises the following steps:

[0033] ① Place the workpiece in a vacuum chamber, use a linear ion beam source to provide an oxygen plasma beam, and accelerate the ion beam to attack the workpiece under a certain bias voltage, causing the diamond-like film on the surface of the workpiece to be modified and partially peeled off.

[0034] ② Use a composite acidic electrolyte with a phosphoric acid volume concentration of 15-30%, a sulfuric acid volume concentration of 0.1%-2%, and a glycerol volume concentration of 1%-5%. The preferred phosphoric acid volume concentration is 20%, and the sulfuric acid volume concentration is 1%, composite acidic electrolyte with glycerol volume concentration of 3%, with the workpiece as the anode, at room temperature, at 10-20A / dm 2 Electrolyze for 5-10min at a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com