In-situ reinforced solid welding wire for welding a welding seam by melting SiC particle reinforced aluminum-based composite material

A technology of particle reinforced aluminum and composite materials, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., to achieve the effect of increasing tensile strength, improving weld strength, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

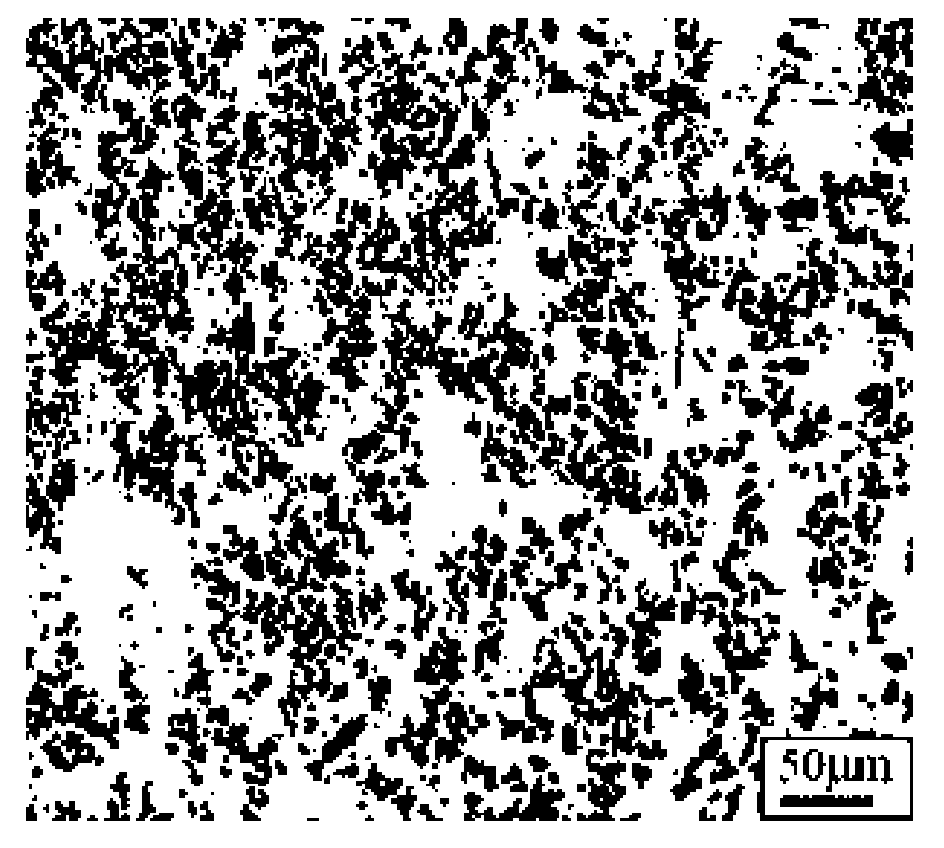

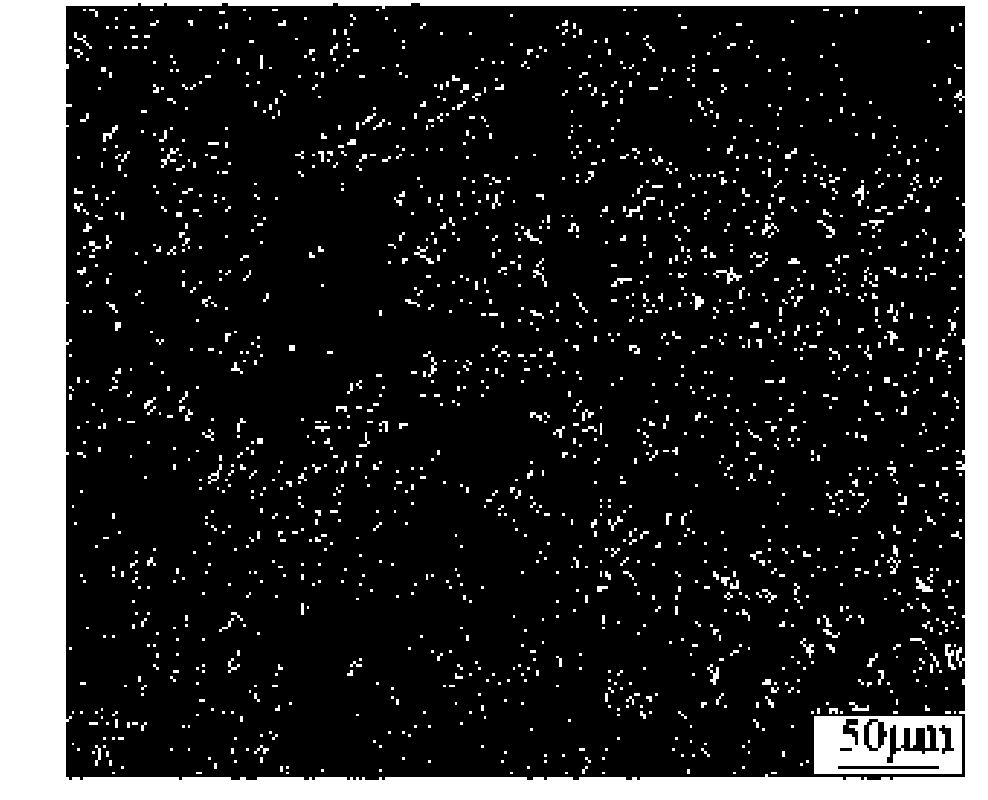

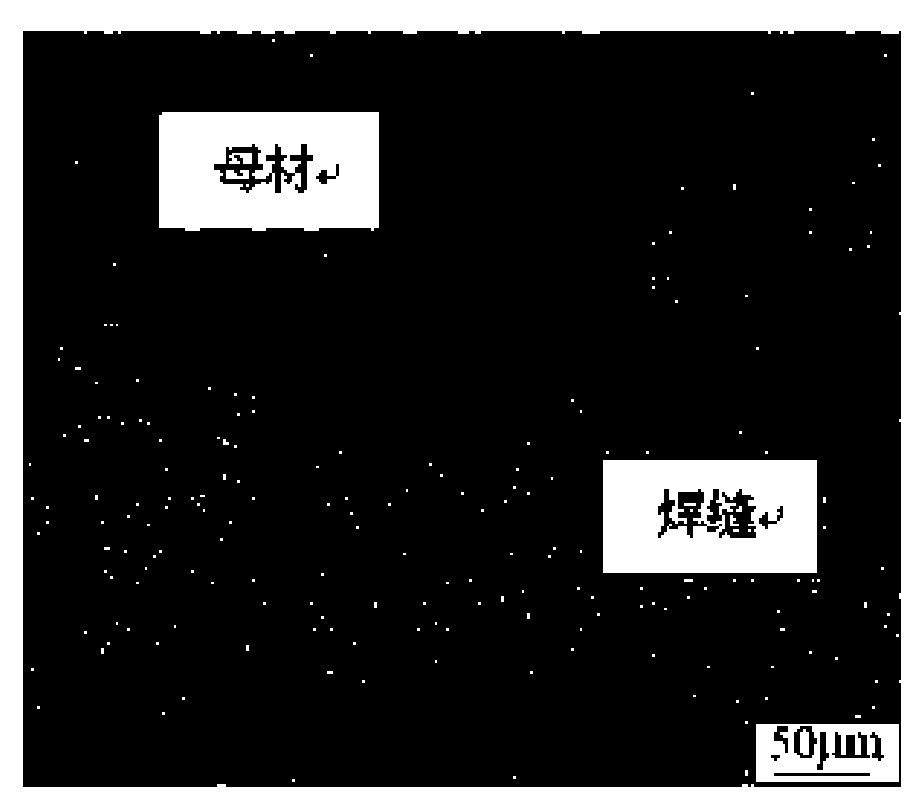

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode 1: In this implementation mode, SiC particle reinforced aluminum matrix composite material fusion welding seam in-situ reinforced solid wire consists of 4%-8% SiC, 5%-10% Si, 1.0%-1.8% Ti, 0.1% to 0.3% of Sc, 0.05% to 0.15% of Y, 0.1% to 0.3% of B, 0.3% to 0.8% of Mg and the rest of Al.

[0015] The welding wire described in this embodiment can be used as a filler for TIG, MIG, plasma arc welding, electron beam welding and laser welding. The strength of the welding seam obtained by the welding wire in this embodiment can reach more than 70% of the base metal.

[0016] The welding wire described in this embodiment can be prepared by the following methods, such as hot pressing drawing method or smelting continuous casting drawing method: the hot pressing drawing method uses a method similar to powder metallurgy to convert the required raw materials into solid particles Form mixing is first pressed into a prefabricated block, then extruded and...

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the SiC particle reinforced aluminum matrix composite material fusion welding seam in-situ reinforced solid core welding wire consists of 5% to 7% SiC, 6% to 8% by mass percentage. %Si, 1.2%-1.6% Ti, 0.1%-0.3% Sc, 0.05%-0.15% Y, 0.12%-0.25% B, 0.3%-0.8% Mg and the rest Al.

[0018] The welding wire described in this embodiment can obtain a weld strength of more than 70.4% of the base metal; the welding wire can be prepared by the method described in Embodiment 1.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one is: SiC particle reinforced aluminum matrix composite material fusion welding seam in-situ reinforced solid core welding wire is composed of 5.5% to 6.5% SiC, 5.5% to 7% by mass percentage %Si, 1.1%-1.5% Ti, 0.1-0.3% Sc, 0.05-0.15% Y, 0.15%-0.2% B, 0.3%-0.8% Mg and the rest Al.

[0020] The welding wire described in this embodiment can obtain a weld strength of more than 70.6% of the base metal; the welding wire can be prepared by the method described in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com