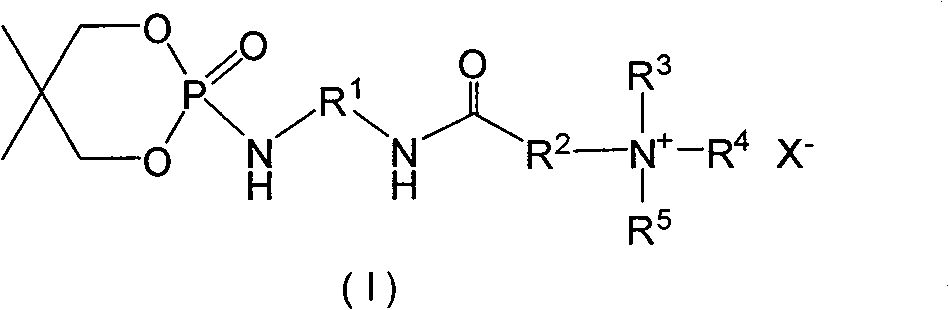

Phosphorus-nitrogen quaternary ammonium as well as preparation method and application thereof

A quaternary ammonium salt, phosphorus nitrogen technology, applied in chemical instruments and methods, dyed low molecular organic compound treatment, organic chemistry, etc. and other problems, to solve the migration problem, increase the flame retardant performance, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

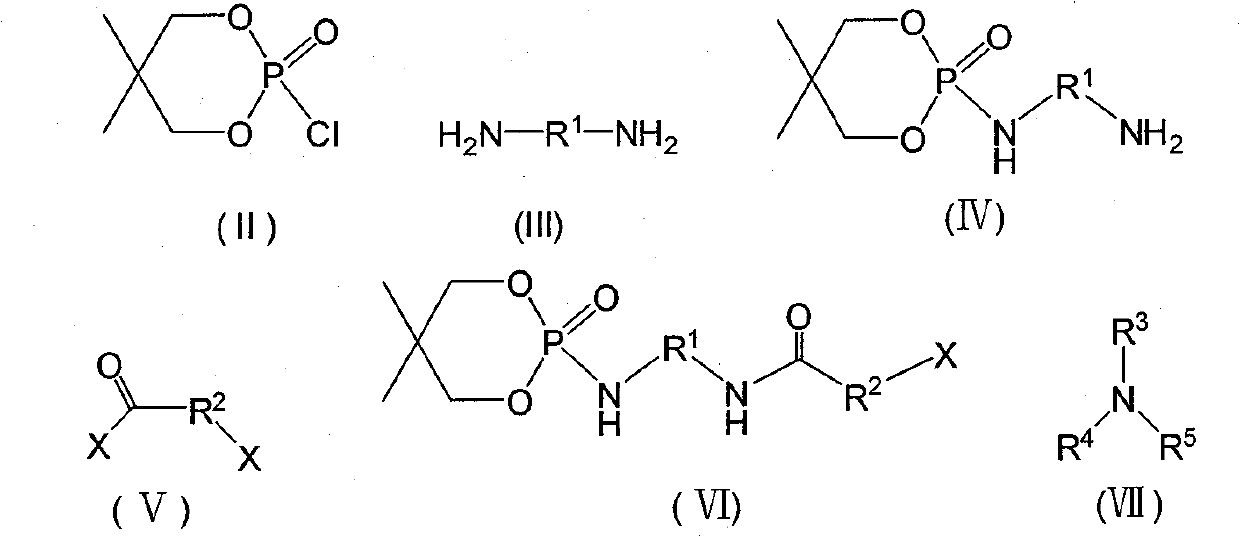

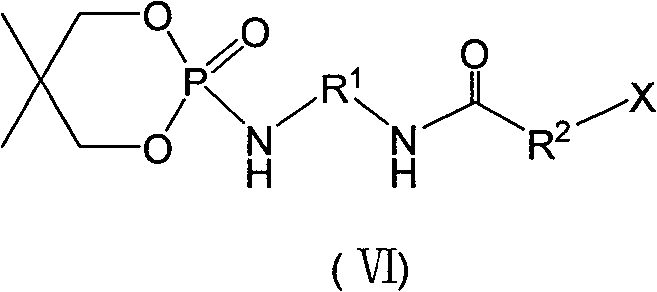

[0041]Example 1: Synthesis of 2-oxo-5,5-dimethyl-1,3,2-dioxaphosphorinane-ethylenediamine

[0042] Add 15.4g (0.1mol) of phosphorus oxychloride and 50mL of chloroform into a four-necked flask, stir the reaction temperature to 35°C, slowly add dropwise a mixture of 10.4g (0.1mol) of neopentyl glycol and 80mL of chloroform, After the addition, the reaction was maintained at 40°C for 3 hours, the chloroform was recovered by distillation under reduced pressure, washed with 25 mL of anhydrous ether, and filtered to obtain a colorless crystalline solid of 2-oxo-2-chloro-5,5-dimethyl -1,3,2-Dioxaphosphorinane, the yield is 86.1%, the purity is 97.1%, and the melting point is 109-110°C. Add 9.0g (0.15mol) of ethylenediamine and 40mL of chloroform into the three-necked flask, stir, and the temperature of the reaction solution is 0°C, slowly add 18.4g (0.1mol) of the solid (2-oxo-2 -Chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane) and 100mL chloroform mixture, after the addition, keep the...

Embodiment 2

[0044] The synthesis operation of 2-oxo-5,5-dimethyl-1,3,2-dioxaphosphorinane-ethylenediamine is the same as in Example 1. In the reaction of the formula (II) compound and the formula (III) compound, the amount ratio of the feed material of the formula (II) compound and the formula (III) compound is 1.0: 3.0, the solvent is selected diethyl ether, the reaction temperature is -30 ℃, and the reaction time is After 5 hours, the yield was 45.4%.

Embodiment 3

[0046] The synthesis operation of 2-oxo-5,5-dimethyl-1,3,2-dioxaphosphorinane-ethylenediamine is the same as in Example 1. In the reaction of the formula (II) compound and the formula (III) compound, the amount ratio of the feed material of the formula (II) compound and the formula (III) compound is 1.0: 2.5, the solvent is selected diethyl ether, the reaction temperature is -20 ℃, and the reaction time is After 7 hours, the yield was 65.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com