Buffer solution for acid processing of the surface of phosphate laser glass and processing method

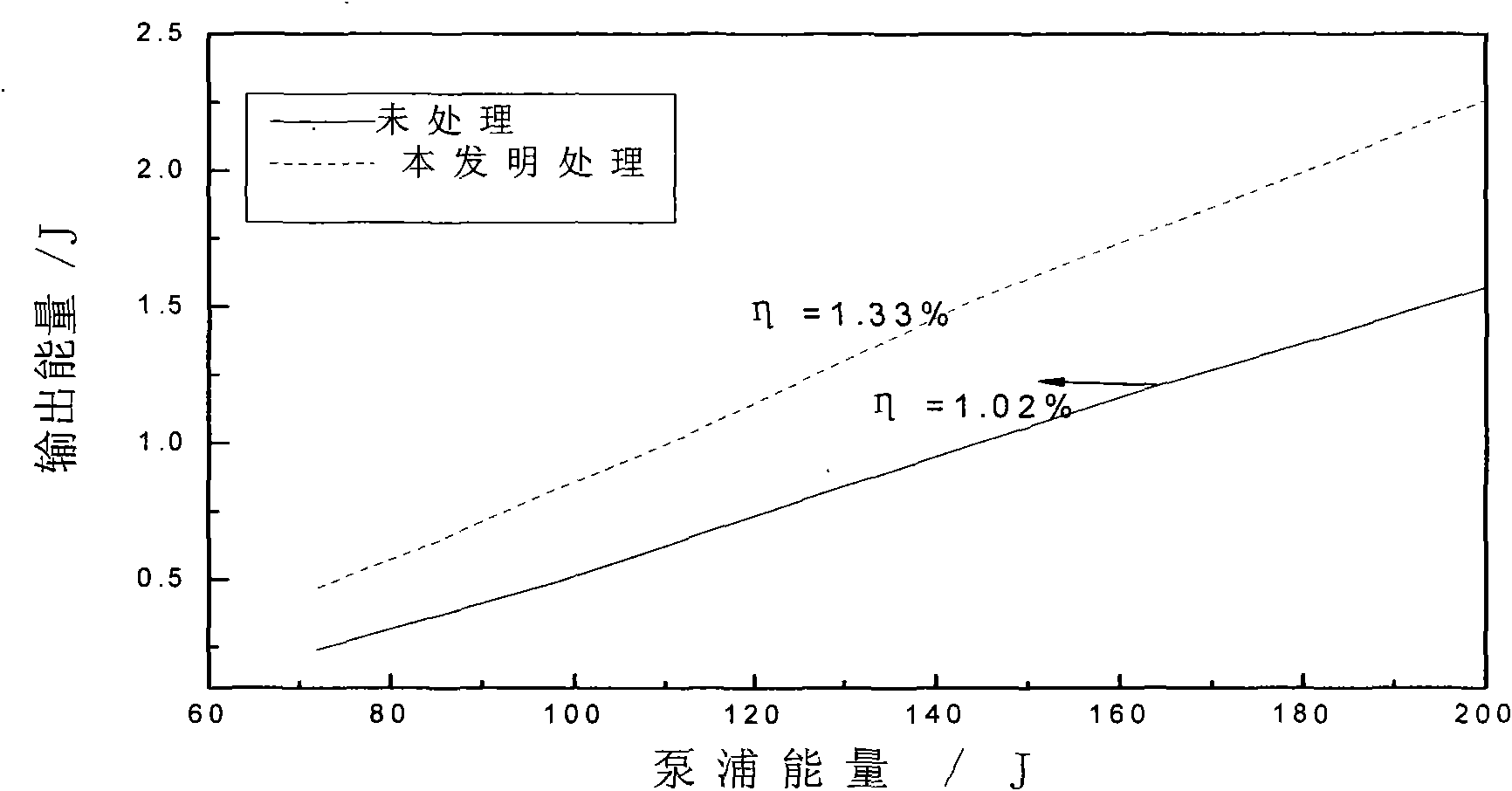

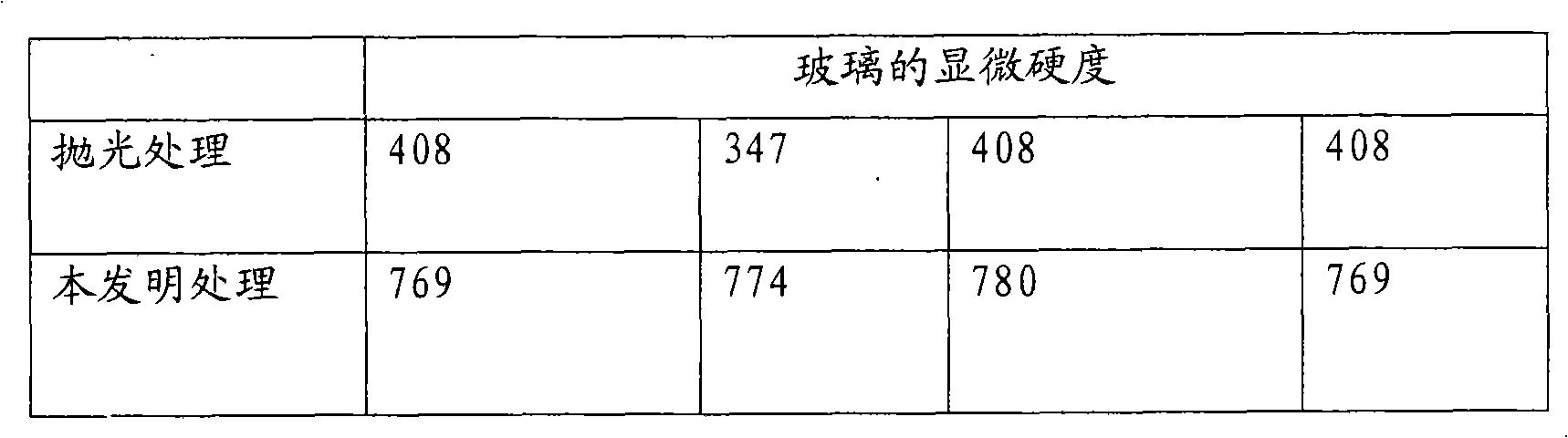

A laser glass and surface treatment technology, applied in the direction of active medium materials, etc., can solve problems such as unevenness, difficult to achieve corrosion effect, affecting corrosion effect, etc., to improve thermal shock resistance, eliminate glass surface defects, and improve surface Effects of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0025] The composition of the acid buffer solution of the present embodiment phosphate laser glass surface treatment:

[0026] The first buffer system is Cl 3 COOH and Cl 3 The aqueous solution of COONa is a mixed solution with a volume ratio of 1:1, wherein Cl 3 COOH and Cl 3 COONaCl 3 The concentration of COOK aqueous solution is 1.00mol / L;

[0027] The second buffer system is a mixed solution of HF and NaF in a volume ratio of 1:1, wherein the concentration of HF is 1.00mol / L, and the concentration of NaF is 6.00mol / L;

[0028] The first buffer system and the second buffer system are mixed according to the volume ratio, and the value range of the volume ratio is 4:1, and then nitric acid is added to adjust the pH value of the acid buffer solution to 1.00.

[0029] Processing method of the present invention has the following steps:

[0030] first step:

[0031] First treat the sample with 4.0mol / l NaOH at 100°C for 10 minutes;

[0032] Step two:

[0033] The sample ...

no. 2 example

[0039] The composition of the acid buffer solution of the present embodiment phosphate laser glass surface treatment:

[0040] The first buffer system is Cl 3 COOH and Cl 3 The aqueous solution of COOK is a mixed solution of 1:1 by volume, in which Cl 3 COOH and Cl 3 The concentration of COOK aqueous solution is 1.00mol / L;

[0041] The second buffer system is HF, NH 4 The aqueous solution of F is a mixed solution with a volume ratio of 1:1, in which the concentration of HF is 1.00mol / L, NH 4 F concentration is 6.00mol / L;

[0042] The first buffer system and the second buffer system are mixed according to the volume ratio, and the value range of the volume ratio is 7:3, and then nitric acid is added to adjust the pH value of the acid buffer solution to 1.00.

[0043] Processing method of the present invention has the following steps:

[0044] first step:

[0045] First treat the sample with 4.0mol / l NaOH at 100°C for 40 minutes;

[0046] Step two:

[0047] The sample ...

no. 3 example

[0053] The composition of the acid buffer solution of the present embodiment phosphate laser glass surface treatment:

[0054] The first buffer system is Cl 3 COOH and Cl 3 The aqueous solution of COONa is a mixed solution with a volume ratio of 1:1, wherein Cl 3 COOH and Cl 3 The concentration of COONa aqueous solution is all 1.00mol / L;

[0055] The second buffer system is HF, NH 4 The aqueous solution of F is a mixed solution with a volume ratio of 1:1, in which the concentration of HF is 1.00mol / L, NH 4 The concentration of F is 6.00mol / L;

[0056] The first buffer system and the second buffer system are mixed according to the volume ratio, and the value range of the volume ratio is 3:2, and then nitric acid is added to adjust the pH value of the acid buffer solution to 1.00.

[0057] Processing method of the present invention has the following steps:

[0058] first step:

[0059] First treat the sample with 4.0mol / l NaOH at 90°C for 30 minutes;

[0060] Step two:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com