Method for preparing transition metal doped mesoporous carbon material

A transition metal and mesoporous carbon technology, applied in the field of mesoporous carbon materials, achieves the effects of simple method, reduced preparation cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

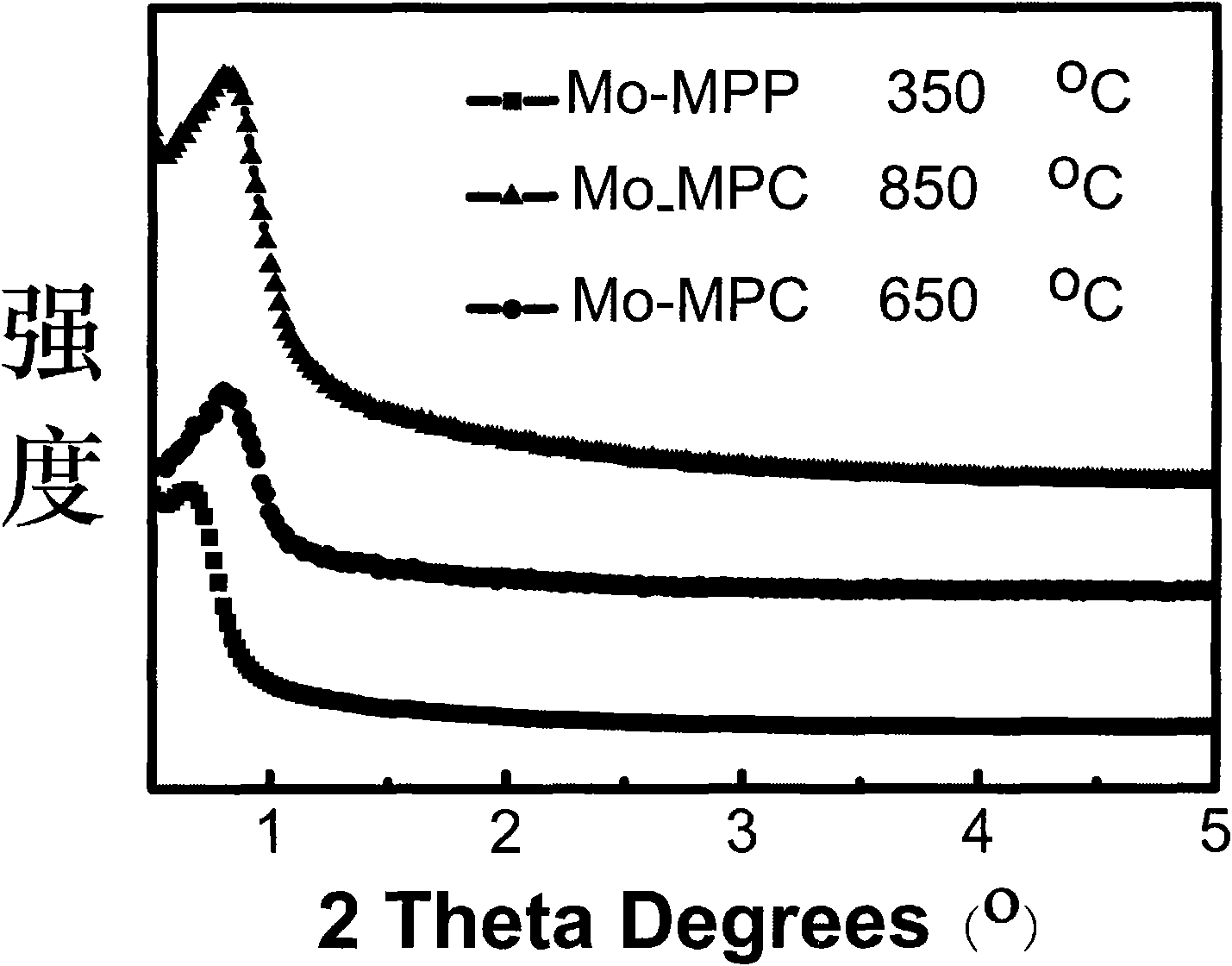

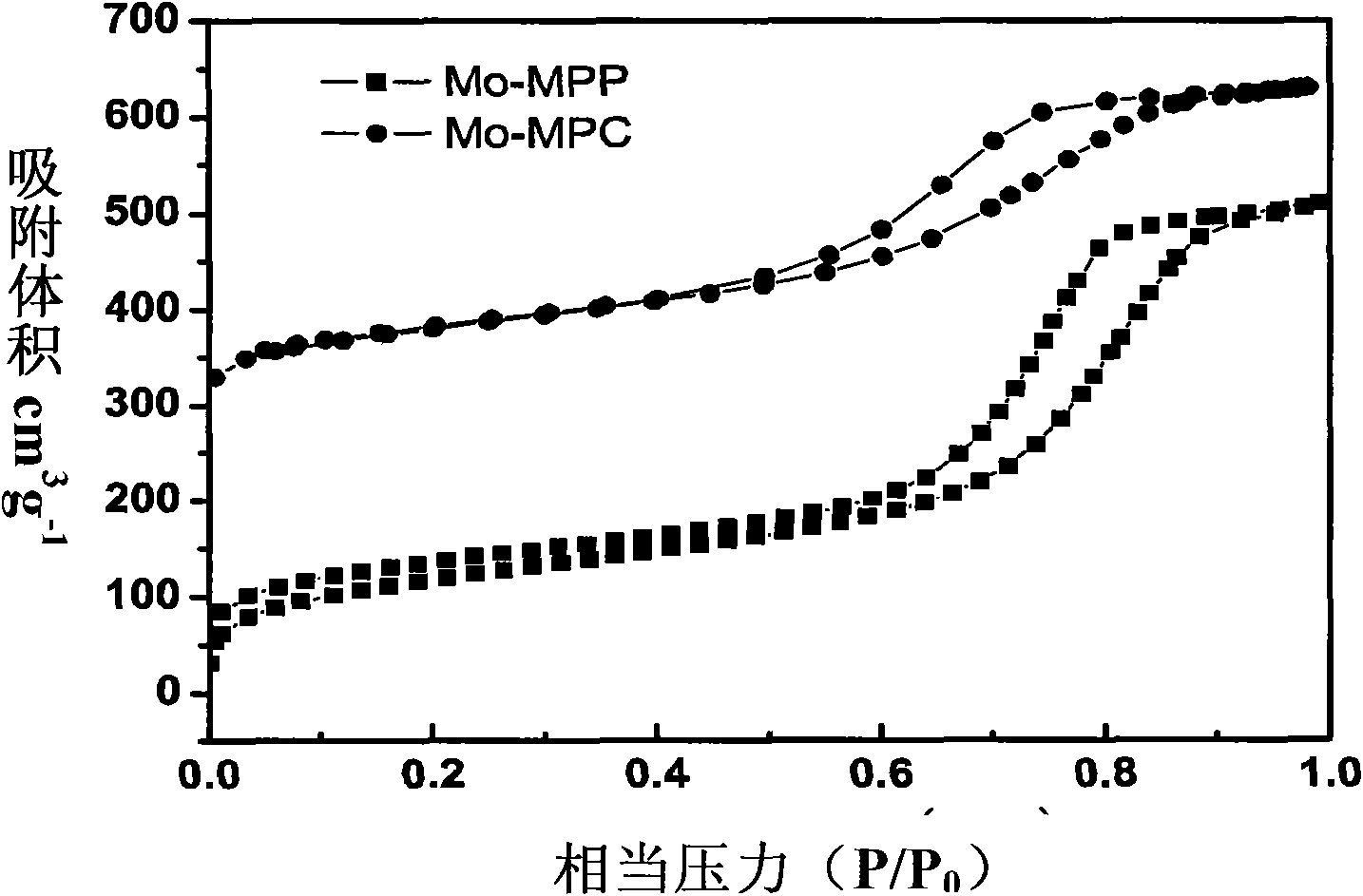

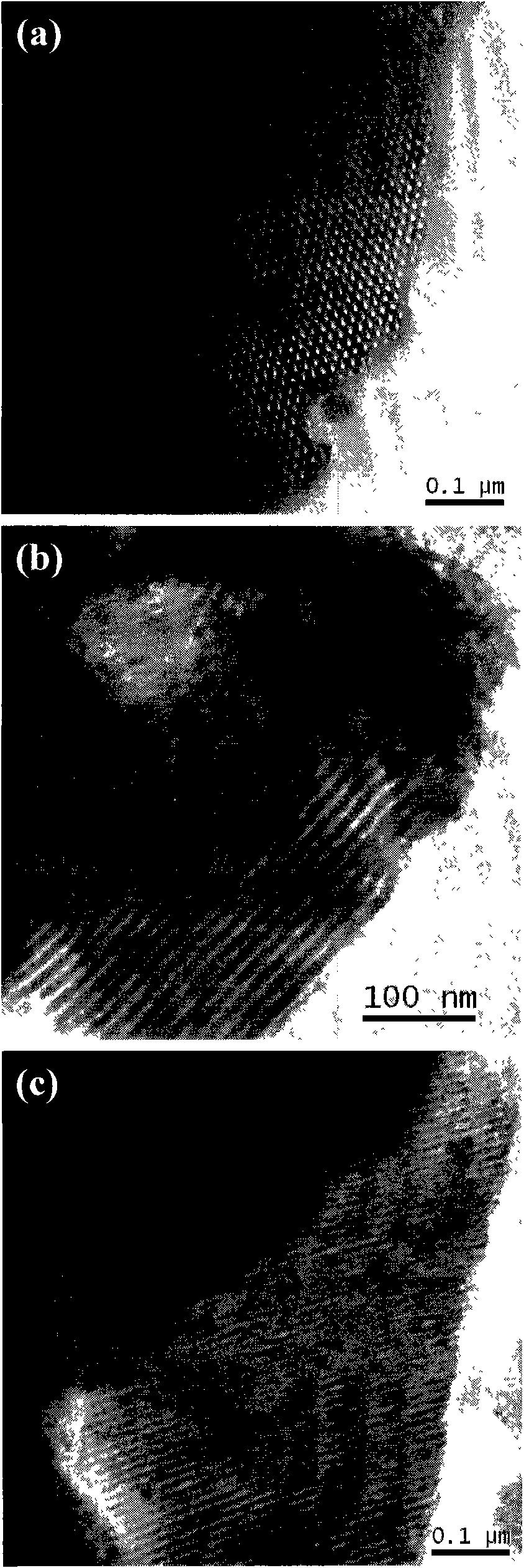

[0041] Phenol (65 grams) and molybdic acid (5 grams) were placed in the beaker, stirred and heated up to 60 ° C, reacted at this temperature for 0.5 hours, added (46 grams) 37% (567 mmol) formaldehyde solution and catalyst oxalic acid 1 g. Continue to stir, reflux for 2 hours, add distilled water, wash away the unreacted reactants, remove the water layer, and distill the remaining water at 150°C under reduced pressure to remove the residual water, discharge the material, and obtain a dark green solid after cooling. The phenolic resin is soluble in ethanol and acetone and is purple in color.

[0042] Get above-mentioned molybdenum-doped phenolic resin 4 grams and be dissolved in 20 milliliters of ethanols, templating agent (triblock polymer Pluronic F127, EO 106 PO 70 EO 106 ) 5 grams were dissolved in 110 milliliters of ethanol, mixed at room temperature, stirred for 2 hours, added 0.92 grams of curing agent hexamethylenetetramine, continued to stir for 24 hours, and static...

Embodiment 2

[0044] Phenol (65 g) and tungstic acid (7.75 g) were placed in a beaker, stirred and heated to 70° C., after reacting at this temperature for 3 hours, added (46 g) 37% (567 mmol) formaldehyde solution and 1 g oxalic acid. Continue to stir, reflux for 1.5 hours, add distilled water, wash away the unreacted reactants, remove the water layer, and distill the remaining water at 150°C under reduced pressure to remove the residual water, discharge the material, and obtain a yellow-green solid after cooling. The phenolic resin is soluble in ethanol and acetone.

[0045] Dissolve 4 grams of the above-mentioned metal-doped phenolic resin in 20 milliliters of ethanol, dissolve 5 grams of template agent triblock polymer Pluronic F127 in 110 milliliters of ethanol, mix at room temperature, stir for 3 hours, add 0.92 grams of curing agent, and continue stirring After 72 hours, the solvent was evaporated to obtain a polymer monolith. After curing, the template agent is removed by firing a...

Embodiment 3

[0047] Phenol (65 grams) and zirconium oxychloride (5.5 grams) were placed in the beaker, stirred and heated up to a certain temperature of 50 ° C, after reacting at this temperature for 0.5 hours, added (46 grams) of 37% (567 mmol) formaldehyde aqueous solution and 1 g of oxalic acid. Continue to stir, reflux for 2.5 hours, add distilled water, wash away the unreacted reactants, remove the water layer, remove the remaining water under reduced pressure at 150°C, discharge the material, and obtain an orange solid after cooling. The phenolic resin is soluble in ethanol and acetone.

[0048] Dissolve 4 grams of the above-mentioned metal-doped phenolic resin in 25 milliliters of ethanol, dissolve the three-block polymer Pluronic F127 (5 grams) of template agent in 110 milliliters of ethanol, mix at room temperature for 3 hours, add 0.92 grams of curing agent, and continue stirring After 24 hours, the solvent was evaporated to obtain a polymer monolith. After curing, the template...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com