Curing agent for high-strength polymer grouting and preparation process thereof

A polymer and curing agent technology, applied in the field of curing agent, can solve problems such as accelerated reaction and violent polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

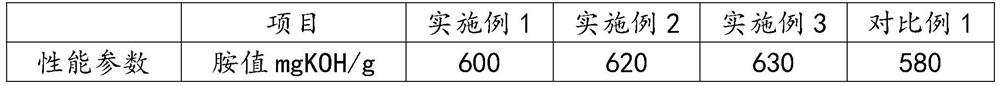

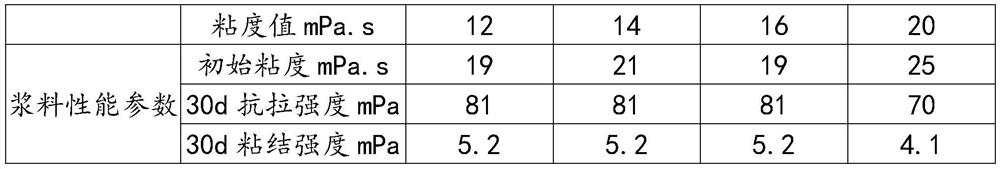

Examples

Embodiment 1

[0036] A curing agent for high-strength polymer grouting, comprising the following raw materials in parts by weight: 20 parts of the first component, 23 parts of the second component, 30 parts of formaldehyde, 30 parts of melamine, 50 parts of deionized water, and 200.1 parts of spar;

[0037] The curing agent for high-strength polymer grouting is prepared through the following steps:

[0038] The first step, preparing the first component and the second component;

[0039] The second step is to add formaldehyde, melamine and deionized water into the reaction kettle and mix evenly to obtain a mixed solution. Use sodium hydroxide to adjust the pH of the mixed solution to 9, set the temperature to 70°C, and the speed to 300r / min, and stir for 50 minutes , to obtain the prepolymer solution for subsequent use;

[0040] The third step is to mix the first component, the second component and Span 20; under the condition of rotating speed of 1000r / min, stir at room temperature for 5min,...

Embodiment 2

[0051] A curing agent for high-strength polymer grouting, comprising the following raw materials in parts by weight: 20-30 parts of the first component, 24 parts of the second component, 35 parts of formaldehyde, 40 parts of melamine, 55 parts of deionized water, and 200.2 parts of Span share;

[0052] The curing agent for high-strength polymer grouting is prepared through the following steps:

[0053] The first step, preparing the first component and the second component;

[0054] The second step is to add formaldehyde, melamine and deionized water into the reaction kettle and mix evenly to obtain a mixed solution. Use sodium hydroxide to adjust the pH value of the mixed solution to 9, set the temperature to 75°C, and the speed to 300r / min, and stir for 55 minutes , to obtain the prepolymer solution for subsequent use;

[0055] The third step is to mix the first component, the second component and Span 20; under the condition of rotating speed of 1000r / min, stir at room tem...

Embodiment 3

[0066] A curing agent for high-strength polymer grouting, comprising the following raw materials in parts by weight: 30 parts of the first component, 25 parts of the second component, 40 parts of formaldehyde, 50 parts of melamine, 60 parts of deionized water, and 200.3 parts of spar;

[0067] The curing agent for high-strength polymer grouting is prepared through the following steps:

[0068] The first step, preparing the first component and the second component;

[0069] The second step is to add formaldehyde, melamine and deionized water into the reaction kettle and mix evenly to obtain a mixed solution. Use sodium hydroxide to adjust the pH value of the mixed solution to 10, set the temperature to 80°C, and the speed to 300r / min, and stir for 60 minutes , to obtain the prepolymer solution for subsequent use;

[0070] The third step is to mix the first component, the second component and Span 20; under the condition of rotating speed of 1000r / min, stir at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com