Conductive engineering plastics and preparation method thereof

A technology of engineering plastics and ABS plastics, which is applied in the field of conductive engineering plastics and its preparation, can solve the problems of dust removal, large amount of conductive fillers, etc., and achieve the effects of small warpage, stable size and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The embodiment of the present invention also provides a preparation method of the above-mentioned conductive engineering plastics, comprising the following steps:

[0043] (1) Proportioning raw materials according to the above-mentioned ratio, mixing each component except acicular wollastonite and carbon nanotubes evenly, and then adding them to the main feeding port of the twin-screw extruder;

[0044] (2) After mixing the acicular wollastonite and carbon nanotubes, add them to the side feeding port;

[0045] (3) Extrude, cool, dry, and pelletize after fully kneading the polymer resin in a molten state to form a composite plastic.

[0046] The melt extrusion temperature in the above step (1) is 260-310°C.

Embodiment 1

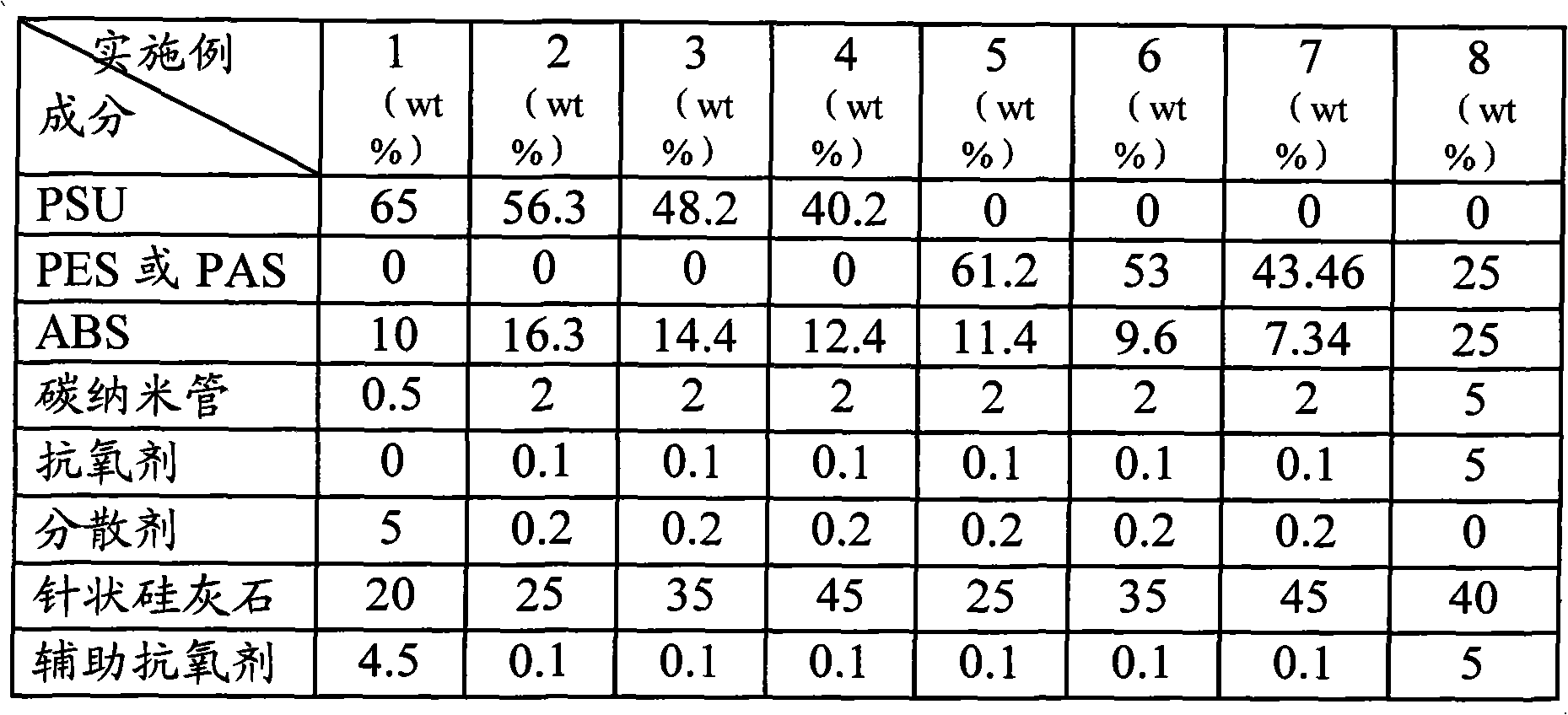

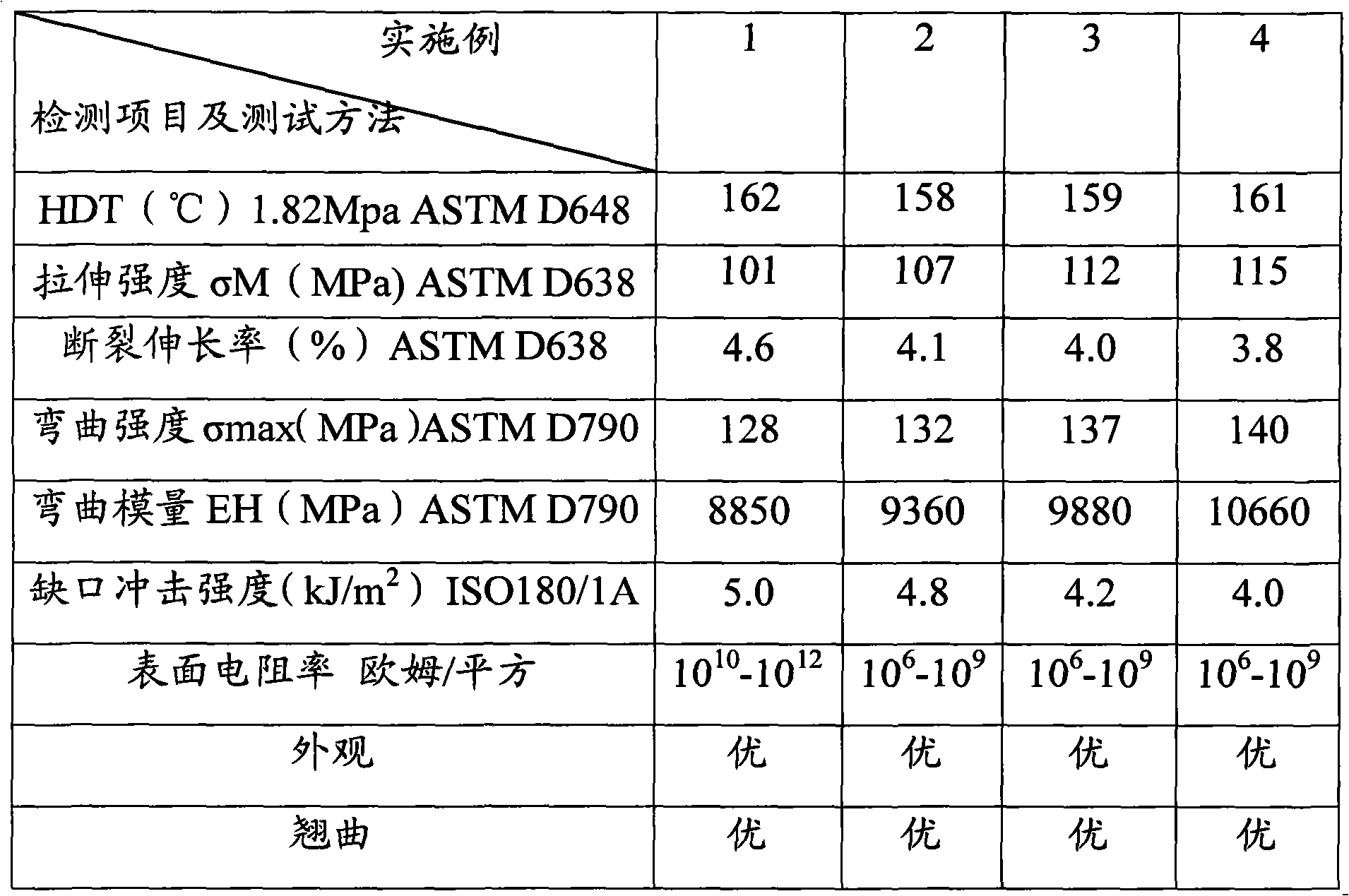

[0048] According to the data of Example 1 in Table 1, all components except acicular wollastonite and carbon nanotubes are mixed uniformly according to the proportion and then melted and extruded through a twin-screw extruder, and acicular wollastonite and carbon nanotubes are added to the side feed port. Nanotubes (mixed according to the proportion through a high-speed mixer), granulation, that is, the granular products of the composition of the present invention are obtained. The twin-screw extruder adopts the CTE-35 (L / D=48) twin-screw extruder produced by Nanjing Keya Company, the extrusion temperature is 260-310° C., and the screw speed is 290 RPM.

[0049] The pellets were dried at 110°C for 4 hours, then injection molded into ASTM bars to measure their properties. The results are shown in Table 2.

Embodiment 2

[0051]According to the data of Example 2 in Table 1, all components except acicular wollastonite and carbon nanotubes are mixed uniformly according to the proportion and then melted and extruded through a twin-screw extruder, and acicular wollastonite and carbon nanotubes are added to the side feed port. Nanotubes (mixed according to the proportion through a high-speed mixer), granulation, that is, the granular products of the composition of the present invention are obtained. The twin-screw extruder adopts the CTE-35 (L / D=48) twin-screw extruder produced by Nanjing Keya Company, the extrusion temperature is 260-310° C., and the screw speed is 290 RPM.

[0052] The pellets were dried at 110°C for 4 hours, then injection molded into ASTM bars to measure their properties. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com