Graphite water-base cathode formula and preparation method thereof

A graphite anode, water-based technology, applied in electrode manufacturing, active material electrodes, etc., can solve the problems of high production cost of oil-based system batteries, large environmental pollution, unstable water-based system slurry, etc., and achieve low production costs and environmental pollution. , the effect of slurry stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

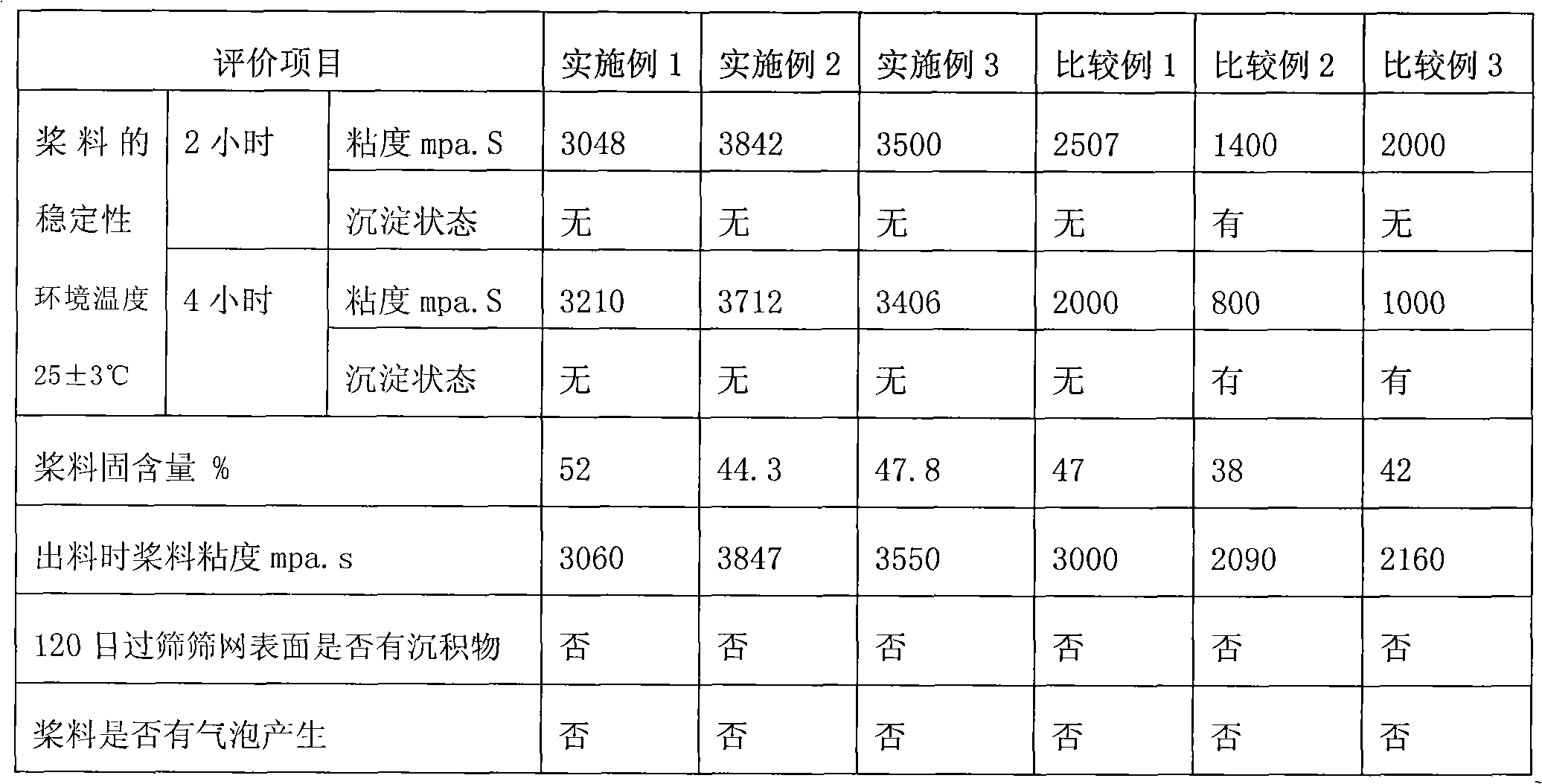

Examples

Embodiment 1

[0017] In parts by weight, the formula of the present invention is:

[0018] Graphite negative electrode 100 parts

[0019] 40 parts of water-based adhesive

[0020] 60 parts deionized water

[0021] Alcohol 4 parts

[0022] Its preparation method is: it comprises the following steps:

[0023] (a): Add 40 parts of the water-based adhesive to the cleaned vacuum mixing tank, then add 60 parts of the deionized water, and start the mixer to stir for 30 to 60 minutes;

[0024] (b): Add 4 parts of the alcohol and stir for 10-30 minutes;

[0025] (c): adding 100 parts of the graphite negative electrode and stirring for 3 to 5 hours;

[0026] (d): The stirred slurry is passed through a sieve of 80-120 meshes to prepare an electrode.

Embodiment 2

[0028] In parts by weight, the formula of the present invention is:

[0029] Graphite negative electrode 100 parts

[0030] 60 parts of water-based adhesive

[0031] 80 parts of deionized water

[0032] Alcohol 6 parts

[0033] The preparation method is the same as that of Example 1, except that: 60 parts of water-based adhesive, 80 parts of deionized water, and 6 parts of alcohol.

Embodiment 3

[0035] In parts by weight, the formula of the present invention is:

[0036] Graphite negative electrode 100 parts

[0037] 50 parts of water-based adhesive

[0038] 70 parts of deionized water

[0039] Alcohol 5 parts

[0040] The preparation method is the same as that of Example 1, except that: 50 parts of water-based adhesive, 70 parts of deionized water, and 5 parts of alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com