Process method for treating solid waste containing copper and nickel

A technology of solid waste and process methods, applied in the direction of improving process efficiency, etc., can solve the problems of small furnace hearth area, large environmental pollution, environmental pollution, etc., to improve environmental pollution problems, reduce pollution such as flying dust, and improve regional environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

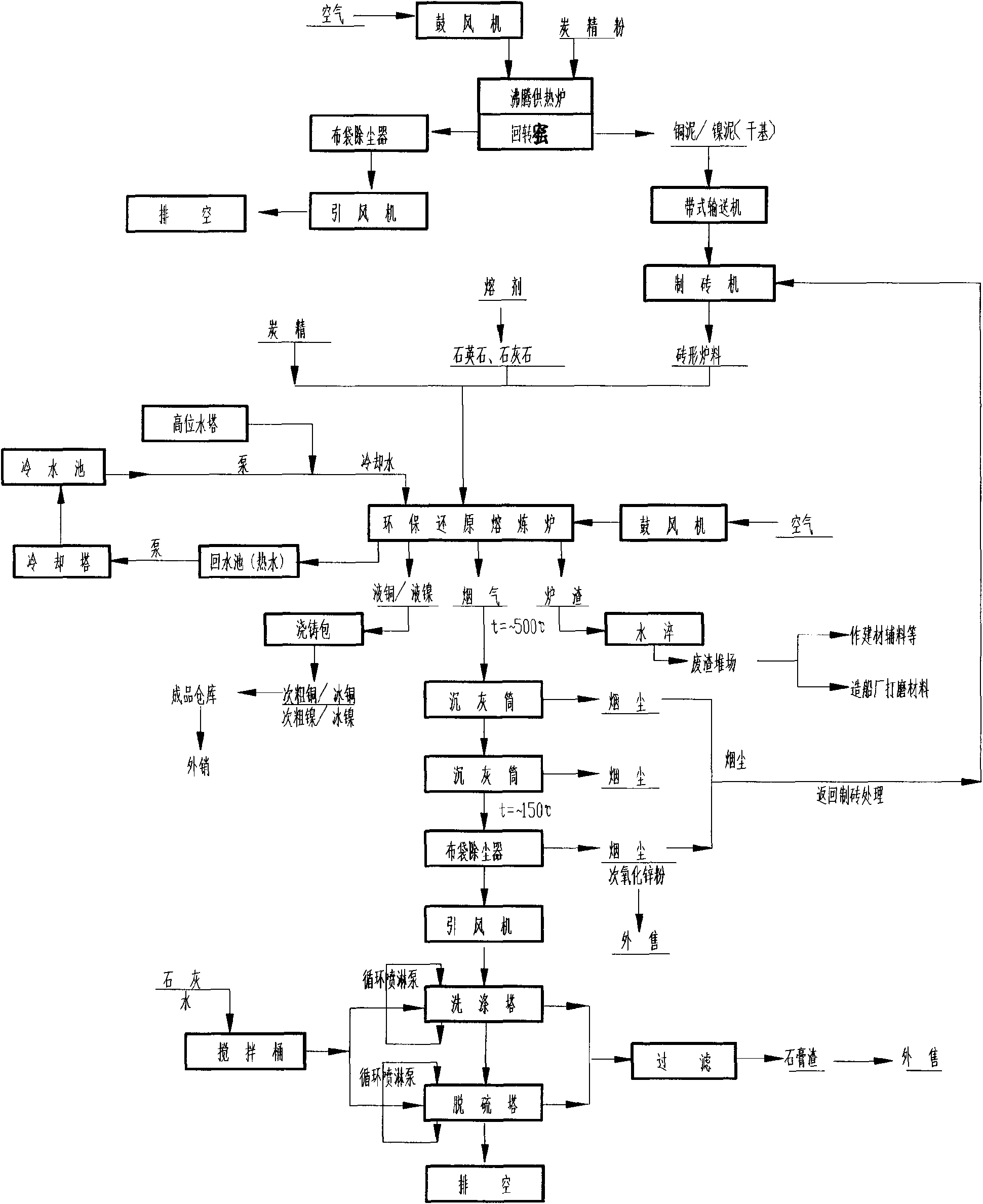

[0014] see figure 1 , because the solid waste has a high water content and a very fine particle size, in order to ensure the temperature in the environmental reduction smelting furnace, increase the gas permeability of the charge, and improve its bed energy rate, this part of the filter mud is input into the boiling heating furnace and the rotary kiln for drying. The drying temperature is 800°C, and then sent to the brick making machine through a belt conveyor to be pressed into a brick-shaped charge with a certain strength and particle size. The brick-shaped charge is a standard brick size of 240*115*53mm. Furnace charge. The heat source required for drying in the rotary kiln comes from the combustion of fine carbon powder produced during the crushing of fine carbon in the production process of the environmental protection reduction method. After drying, the moisture content of solid waste is reduced from 75 to 80% to below 25%. The smoke and dust generated in the rotary kil...

Embodiment 2

[0019] see figure 1 , because the solid waste has a high water content and a very fine particle size, in order to ensure the temperature in the environmental reduction smelting furnace, increase the gas permeability of the charge, and improve its bed energy rate, this part of the filter mud is input into the boiling heating furnace and the rotary kiln for drying. The drying temperature is 900°C, and then sent to the brick making machine by a belt conveyor to be pressed into a brick-shaped charge with a certain strength and particle size. Furnace charge. The heat source required for drying in the rotary kiln comes from the combustion of fine carbon powder produced during the crushing of fine carbon in the production process of the environmental protection reduction method. After drying, the moisture content of solid waste is reduced from 75 to 80% to below 25%. The smoke and dust generated in the rotary kiln are treated by bag filter and induced draft fan in turn and then empt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com