Light-hydrocarbon aromatized catalyst and preparation method thereof

A catalyst and aromatization technology, which is applied in the field of light hydrocarbon aromatization catalysts and its preparation, can solve the problems of rapid deactivation, large catalyst carbon deposits, and a total utilization rate of less than 20%, achieving less carbon deposits and aromatic hydrocarbons High yield and long life per pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

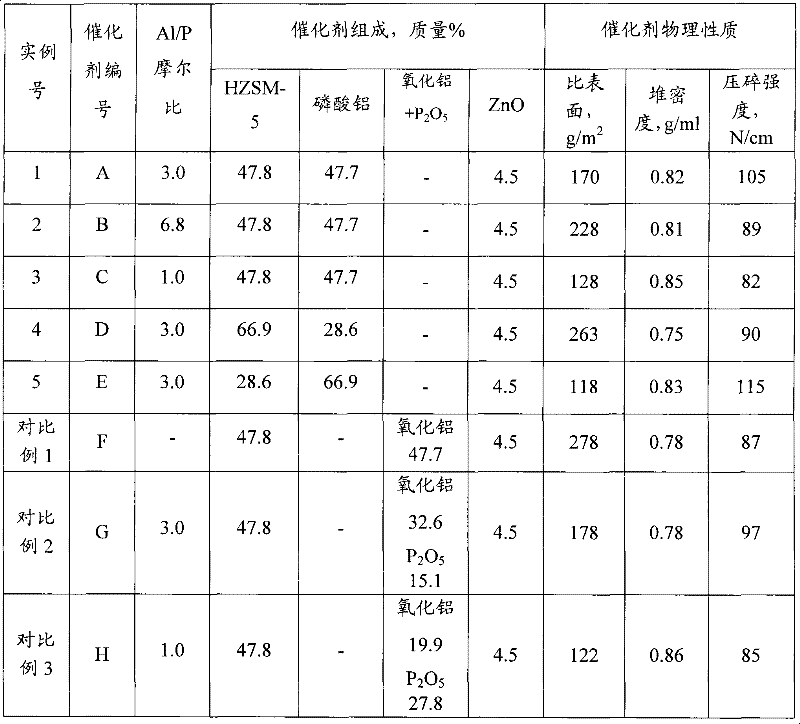

Examples

preparation example Construction

[0019] The preparation method of catalyst provided by the invention comprises the steps:

[0020] (1) impregnating the precursor of alumina with an aqueous solution of a phosphorus-containing compound, drying and roasting to obtain aluminum phosphate;

[0021] (2) mixing hydrogen-type zeolite with an MFI structure and aluminum phosphate, extruding, drying, and roasting to obtain a composite carrier;

[0022] (3) impregnating the above-mentioned composite carrier with a solution containing a zinc compound, then drying and calcining.

[0023] The step (1) of the above method is the preparation of aluminum phosphate, and the precursor of alumina used in it is preferably pseudo-boehmite. The phosphorus-containing compound used to prepare the immersion liquid is preferably phosphoric acid, metaphosphoric acid, ammonium hydrogen phosphate, diammonium hydrogen phosphate or ammonium phosphate. The amount of the phosphorus compound contained in the impregnating liquid should make the...

example 1

[0033] Preparation of the catalyst of the present invention.

[0034] (1) Preparation of aluminum phosphate

[0035] Get 91.2g pseudo-boehmite powder (production of Sasol company, PURAL SB, alumina content 75% by mass), add 120g of diammonium hydrogen phosphate aqueous solution containing 11.5% by mass of phosphorus at 25°C, stir for 1 hour, dry at 110°C for 5 hours, and roast at 550°C for 5 hours to obtain 13.8% by mass of phosphorus And aluminum phosphate containing 36.2% by mass of aluminum has an Al / P molar ratio of 3.0.

[0036] (2) Preparation of composite carrier

[0037] Take 52.6g of HZSM-5 zeolite powder (zeolite content of 95% by mass) with a silica / alumina molar ratio of 55 and 50g of the aluminum phosphate prepared in step (1) and mix evenly, add 50g of nitric acid aqueous solution with a concentration of 1.0% by mass for peptization and kneaded evenly, extruded, dried at 110°C for 6 hours, and calcined at 550°C for 5 hours to obtain a composite carrier with a...

example 2

[0041] Aluminum phosphate is prepared according to the method of example 1 (1) step, the difference is that 110.4g of pseudoboehmite powder is added to 100 grams of phosphorus-containing 7.4% by mass of diammonium hydrogen phosphate aqueous solution, and after drying and roasting, phosphorus-containing The aluminum phosphate containing 7.4% by mass and 43.9% by mass of aluminum has an Al / P molar ratio of 6.8.

[0042] Get above-mentioned aluminum phosphate, prepare catalyst by the method for example 1 (2), (3) step, the composition and physical property of the catalyst B that make are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com