Carrier of catalyst for preparing low-carbon alkene by dehydrogenation of low-carbon alkane and application of carrier

A catalyst carrier, low-carbon alkane technology, applied in the direction of catalyst carrier, hydrocarbons, hydrocarbons, etc., can solve the problems of large carbon deposition, rapid performance degradation and short single-pass life of the catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

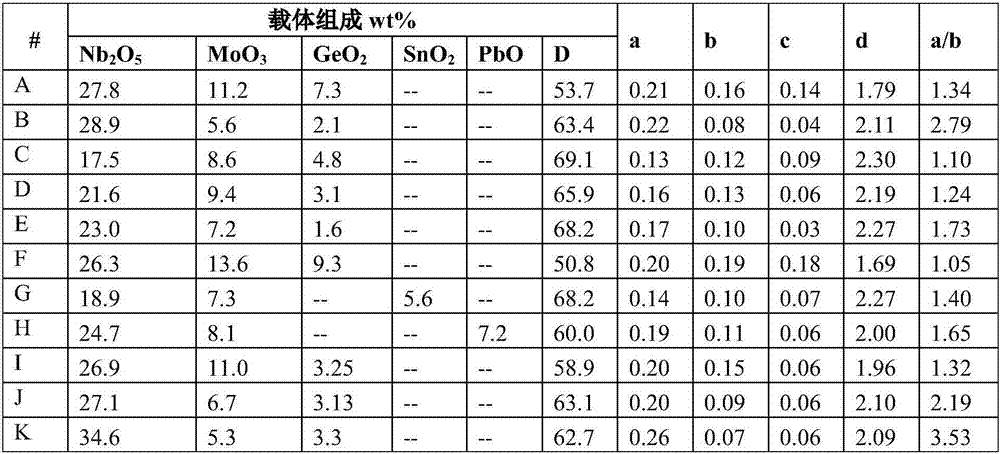

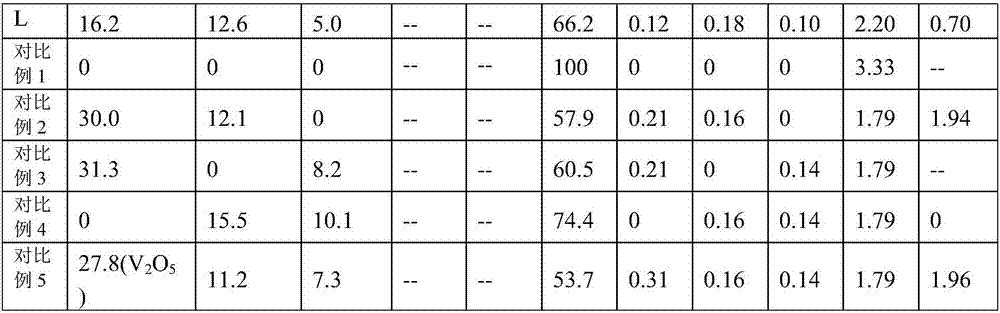

[0026] Get 43.1g oxyfluoroniobic acid (H 2 (NbOF 5 )), 30.5g ammonium molybdate ((NH 4 ) 2 MoO 4 ) was dissolved in 1L of deionized water, and then 107.4g of silicon dioxide (80-120 microns in particle size) and 14.6g of germanium oxide (80-120 microns in particle size) were added to form a suspension; at 22°C, under vigorous stirring, the Slowly add 10% ammonia water dropwise into the mixed aqueous solution to form a precipitate, control the pH value to 7.8, stir for 2 hours, filter, wash with deionized water for 3 times, dry at 120°C, pulverize, and sieve at 700 ℃ for 16 hours to obtain a composite silica carrier. Pore volume 0.49cm 3 / g, specific surface area 87m 2 / g. The composition and properties of the carrier are shown in Table 1.

[0027] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2O, 0.12g) in aqueo...

Embodiment 2

[0030] Get 44.8g oxyfluoroniobic acid (H 2 (NbOF 5 )), 15.3g ammonium molybdate ((NH 4 ) 2 MoO 4 ) was dissolved in 1L deionized water, and then 126.8g of silicon dioxide (particle size 80-110 microns) and germanium oxide 4.2g (particle size 60-100 microns) were added to form a suspension; at 25°C, under vigorous stirring, the Slowly add 6% ammonia water dropwise into the mixed aqueous solution to form a precipitate, control the pH value to 8.0, stir for 2 hours, filter, wash with deionized water for 3 times, dry at 120°C, pulverize, and sieve at 720 ℃ for 12 hours to obtain a composite silica carrier. Pore volume 0.69cm 3 / g, specific surface area 104m 2 / g. The composition and properties of the carrier are shown in Table 1.

[0031] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H 2 PtCl 6 6H 2 O, 0.12g) in aqueous solution ...

Embodiment 3

[0034] Get 27.6g oxyfluoroniobic acid (H 2 (NbOF 5 )), 23.6g ammonium molybdate ((NH 4 ) 2 MoO 4 ) was dissolved in 1L of deionized water, and then 139.2g of silicon dioxide (30-80 microns in particle size) and 9.6g of germanium oxide (60-90 microns in particle size) were added to form a suspension; at 25°C, under vigorous stirring, the 15% ammonia water was slowly added dropwise to the mixed aqueous solution to form a precipitate, and the pH value was controlled to 8.0. After stirring for 2 hours, filter, wash with deionized water for 3 times, dry at 120°C, pulverize, and sieve the mixture at 820 ℃ for 8 hours to obtain a composite silica carrier. Pore volume 0.72cm 3 / g, specific surface area 116m 2 / g. The composition and properties of the carrier are shown in Table 1.

[0035] The obtained carrier adopts impregnation technology to load the platinum component, that is, at room temperature, 15.0 g of the obtained carrier is impregnated with chloroplatinic acid (H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com