A kind of hierarchical porous nano sapo-34 molecular sieve and its preparation method and application

A technology of SAPO-34 and molecular sieve, which is applied in the field of catalysis and can solve problems such as the limitation of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

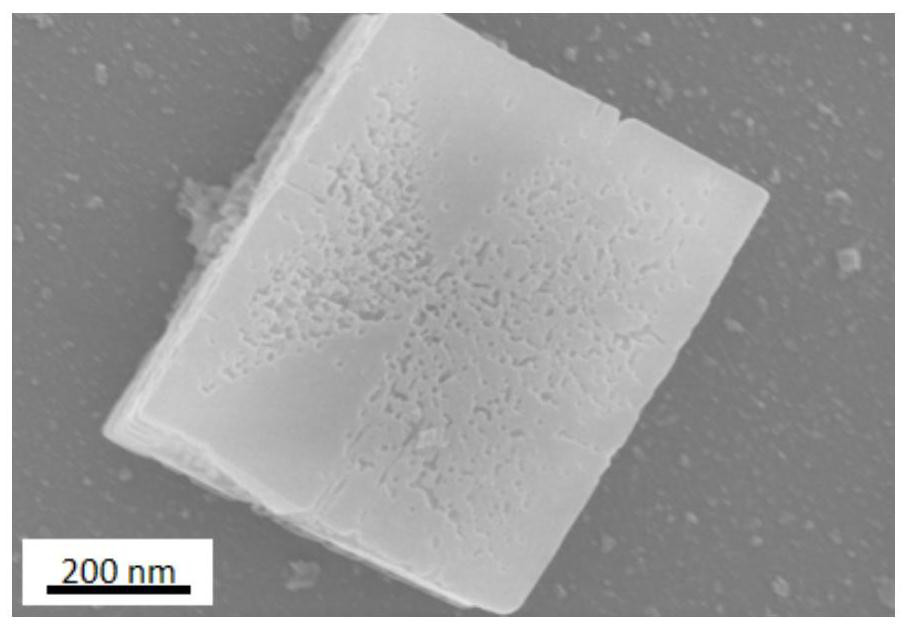

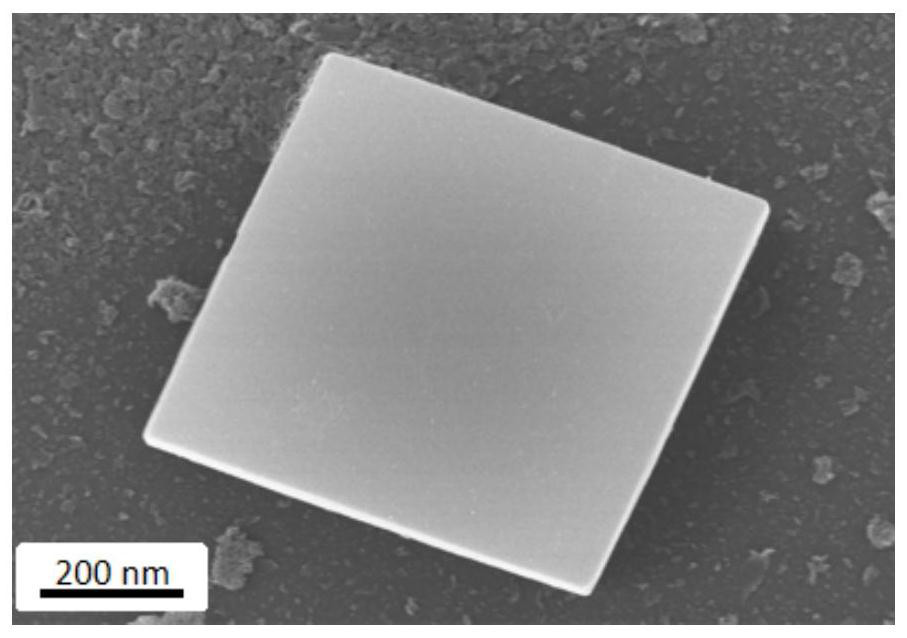

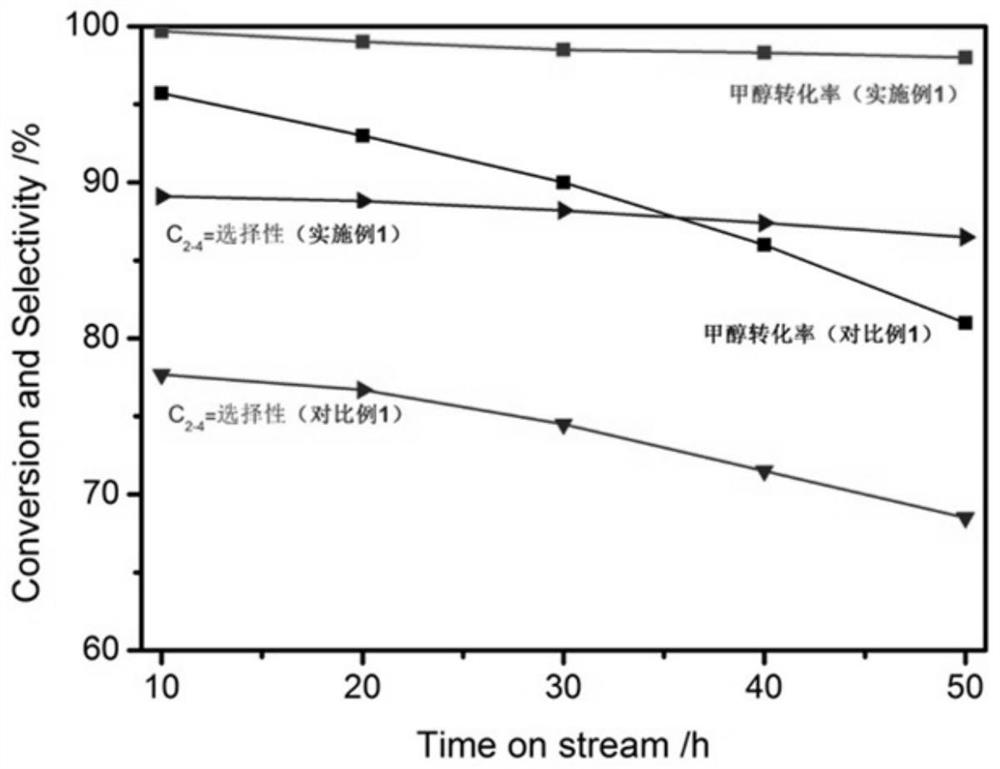

Embodiment 1

[0027] Weigh 3g SAPO-34 and put it in a beaker, then add 0.1g mass fraction of 40% hydrogen fluoride solution, stir at room temperature for 3min to obtain suspension A; weigh 0.2g ammonium fluoride and add it to suspension A, Stir at room temperature for 3 minutes to obtain suspension B; weigh 18g of deionized water and add it to suspension B, stir for 5 minutes to obtain suspension C; put suspension C in an ultrasonic cleaner at 25°C Ultrasound for 15 minutes to obtain suspension D; put suspension D for 1 hour and then remove the supernatant water; then put it in a centrifuge and centrifuge at a speed of 12000r / min, and centrifuge several times until the solution is neutral; then Put it into an oven at 100°C and dry it for 12 hours; place the obtained sample in dry air, raise the temperature to 550°C at a rate of 3°C / min and roast for 6 hours, shape the solid sample after roasting, and sieve to obtain 30-60 Object particles, namely the hierarchically porous nanometer SAPO-34 ...

Embodiment 2

[0030] Weigh 3g SAPO-34 and put it in a beaker, then add 0.2g hydrogen fluoride solution with a mass fraction of 40%, stir at room temperature for 3min to obtain suspension A; weigh 0.2g ammonium fluoride and add it to suspension A , stirred at room temperature for 3 minutes to obtain suspension B; weighed 18 g of deionized water and added to suspension B, stirred for 5 minutes to obtain suspension C; put suspension C in an ultrasonic cleaner at 25 ° C Ultrasound for 15 minutes to obtain suspension D; put the suspension D to stand for 1 hour and remove the supernatant water; then put it in a centrifuge and centrifuge at a speed of 12000r / min, and centrifuge several times until the solution is neutral; then Put it into an oven at 100°C and dry it for 12 hours; place the obtained sample in dry air, raise the temperature to 550°C at a rate of 3°C / min and roast for 6 hours, shape the solid sample after roasting, and sieve to obtain 30~ The 60-mesh particle is the hierarchical poro...

Embodiment 3

[0033]Weigh 3g of SAPO-34 and put it in a beaker, then add 0.3g of hydrogen fluoride solution with a mass fraction of 40%, stir at room temperature for 3min to obtain suspension A; weigh 0.2g of ammonium fluoride and add it to suspension A , stirred at room temperature for 3 minutes to obtain suspension B; weighed 18 g of deionized water and added to suspension B, stirred for 5 minutes to obtain suspension C; put suspension C in an ultrasonic cleaner at 25 ° C Ultrasound for 15 minutes to obtain suspension D; put the suspension D to stand for 1 hour and remove the supernatant water; then put it in a centrifuge and centrifuge at a speed of 12000r / min, and centrifuge several times until the solution is neutral; then Put it into an oven at 100°C and dry it for 12 hours; place the obtained sample in dry air, raise the temperature to 550°C at a rate of 3°C / min and roast for 6 hours, shape the solid sample after roasting, and sieve to obtain 30~ The 60-mesh particle is the hierarchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com