Method for preparing co-doping nanometer TiO2 film with adjustable C and N contents

A co-doping and thin-film technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of uncontrollable doping composition ratio and achieve good activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

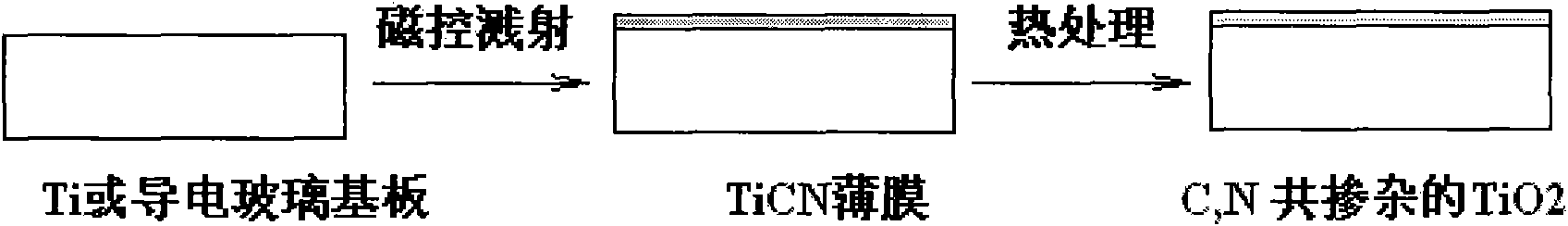

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of carbon-nitrogen co-doped nano-TiO by reactive magnetron sputtering method on the surface of metal titanium sheet or FTO 2 film. First, prepare TiCN film. During sputtering, the area ratio of carbon to titanium in the carbon-titanium mosaic target is 0.06, and the studio is first drawn to 10 -3 Pa-level vacuum, followed by nitrogen (reactive gas) and argon (sputtering gas), adjust the ratio of nitrogen to argon to 1:4, and then adjust the high vacuum valve to keep the working chamber pressure at 2Pa. In terms of pressure, the thickness of the film is controlled by controlling the sputtering current and sputtering time. The sample is annealed in an air atmosphere at 450℃ for 2h.

[0022] Use silver conductive glue to glue the copper wire (10cm×1.5mm) and the conductive surface together, place it under an infrared lamp for 2 hours to dry, and then use one-component room temperature curing silicone rubber 703 to encapsulate the exposed copper wire, sil...

Embodiment 2

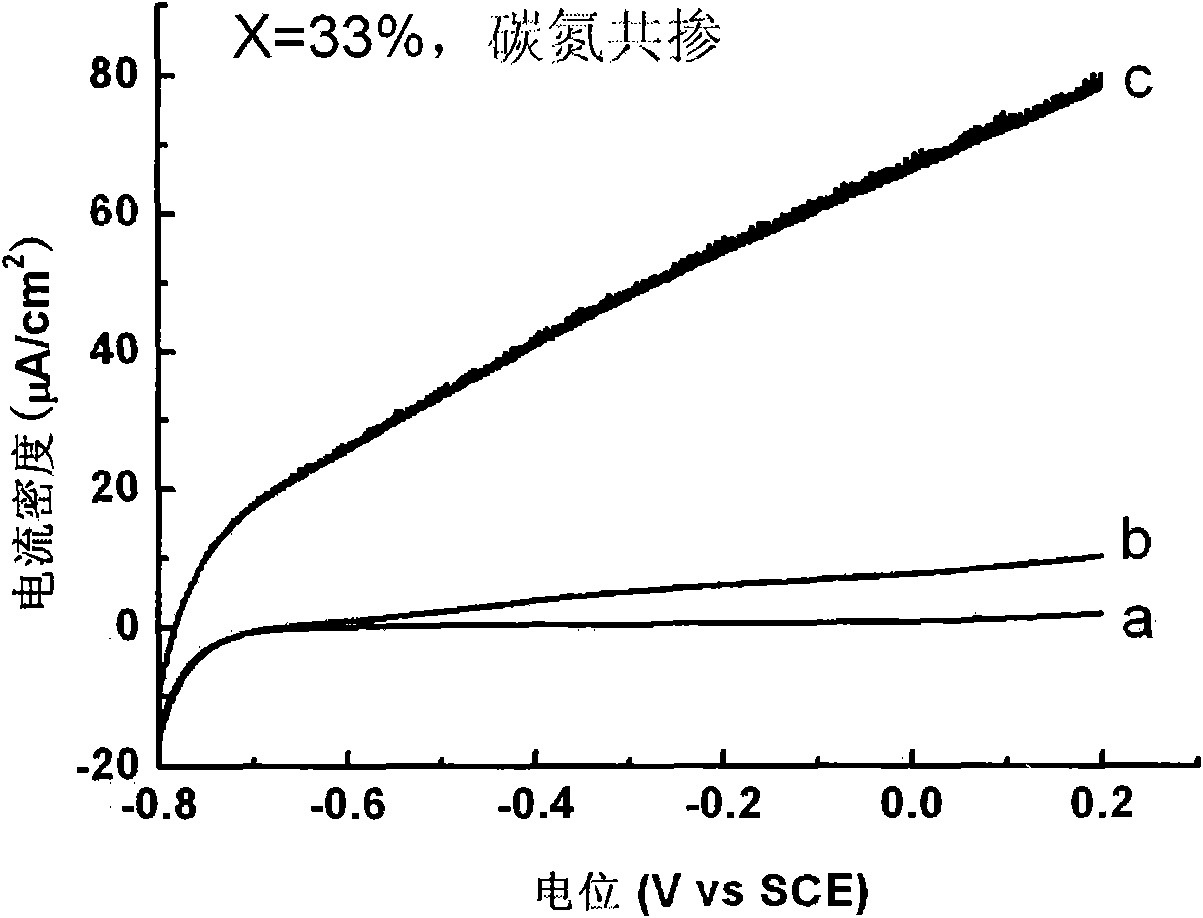

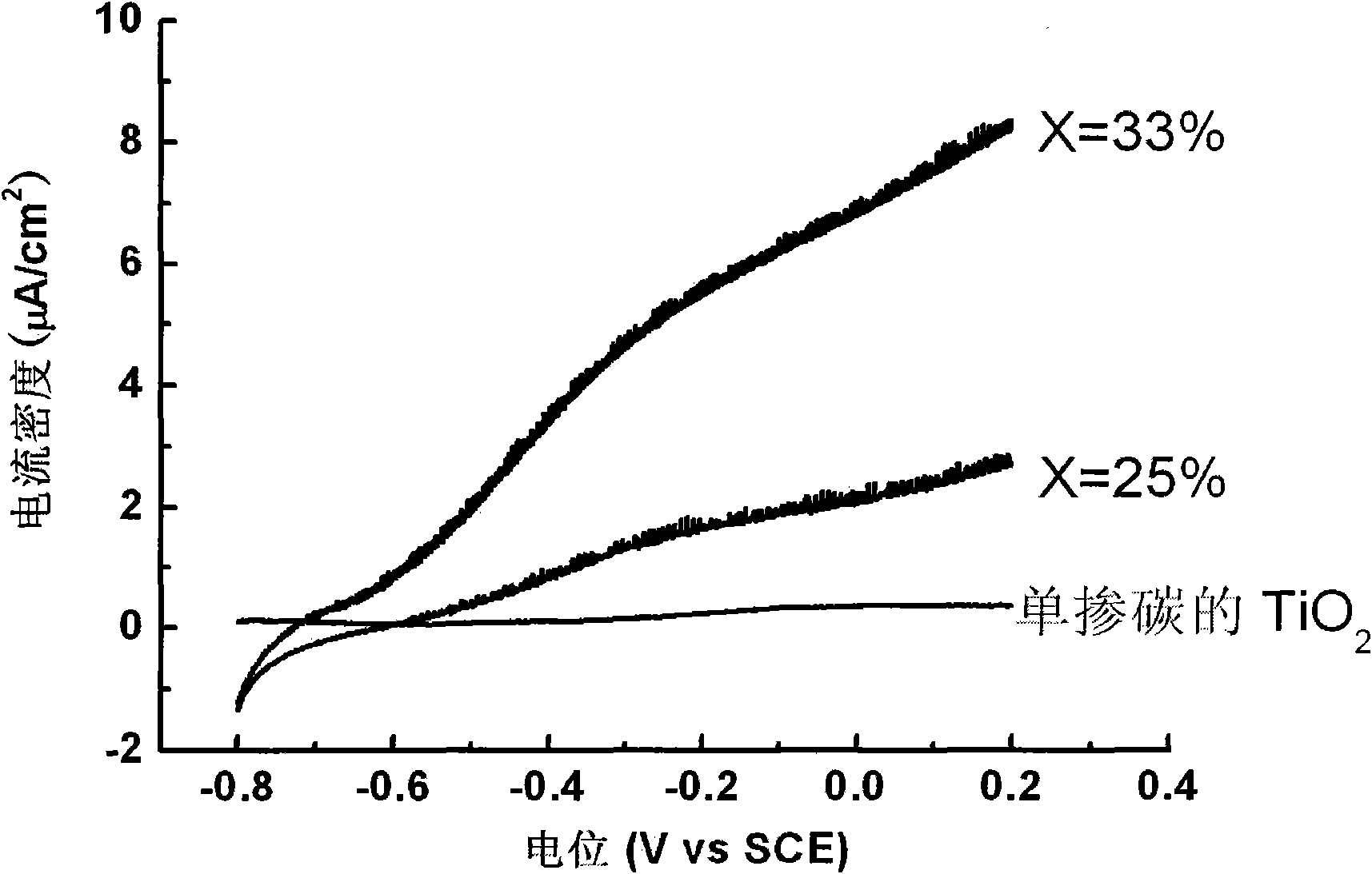

[0024] Example 2: Preparation of TiC and TiCN films by reactive magnetron sputtering, the area of carbon in the carbon titanium embedded target is 10 cm 2 , The area of titanium is 165cm 2 . First draw the studio to 10 -3 Pa-level vacuum, only argon (sputtering gas) sputtered to obtain TiC film, heat treatment to obtain C-doped TiO 2 film. In addition, argon (sputtering gas) and nitrogen (reactive gas) were introduced to adjust the ratio of nitrogen to argon, sputtered to obtain TiCN thin film, and heat treated to obtain C and N co-doped TiO 2 film. In the process of preparing the film, the working chamber pressure was maintained at a sputtering pressure of 2 Pa, the sputtering current was controlled to be 0.5 A, the sputtering time was 2.5 hours, and the sample was annealed in an air atmosphere at 500° C. for 90 minutes.

[0025] Use silver conductive glue to glue the copper wire (10cm×1.5mm) and the conductive surface together, place it under an infrared lamp for 24 hours to...

Embodiment 3

[0027] Example 3: Preparation of nano-TiCN film and carbon-nitrogen co-doped nano-TiO by reactive magnetron sputtering 2 Film (same as Example 1). The carbon and nitrogen co-doped nano TiO 2 The film was placed in a certain amount of methylene blue solution, under ultraviolet light irradiation, the UV-visible absorption spectrum of the methylene blue solution was measured with the irradiation time, and it was found that with the increase of the irradiation time, the absorbance of the methylene blue solution decreased sequentially ( Figure 4 ), indicating that carbon and nitrogen co-doped nano-TiO 2 The film has good degradation activity for methylene blue. Explain that the carbon and nitrogen co-doped nano TiO proposed by the present invention 2 The film is expected to be used in photocatalytic degradation of organic pollutants. Figure 5 Shows different ratios of carbon and nitrogen co-doped nano-TiO 2 The photocatalytic degradation activity of the film is compared with image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com