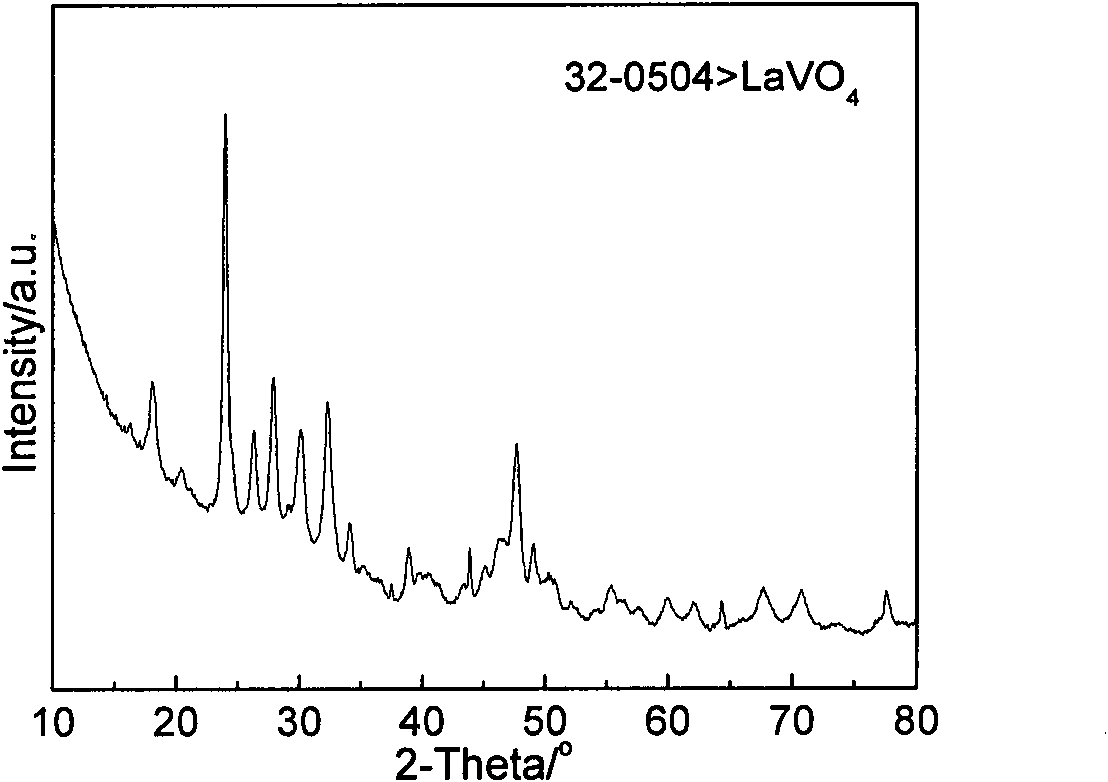

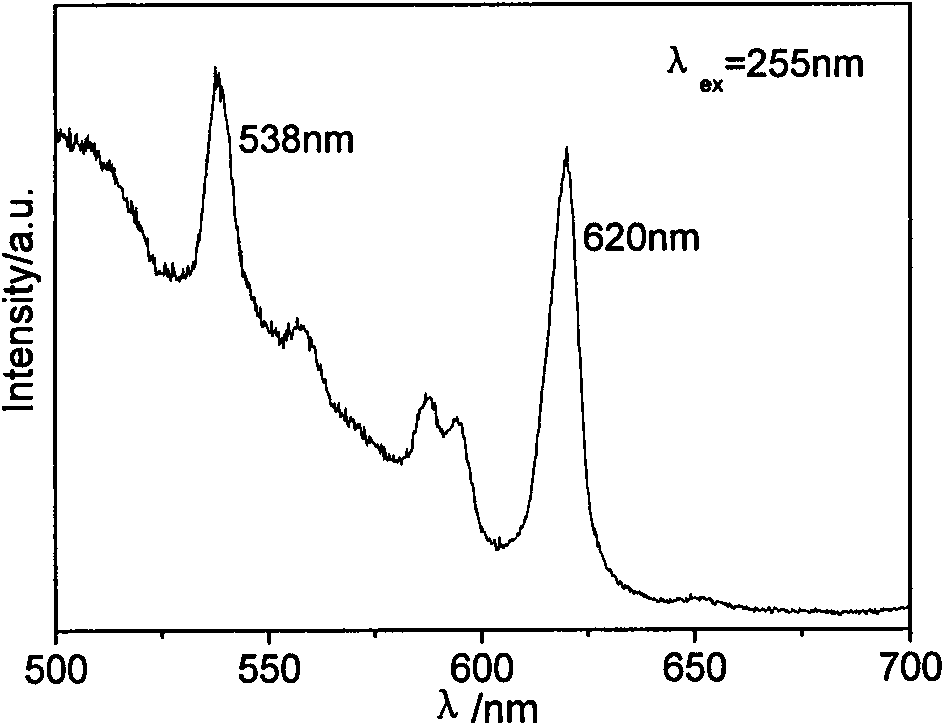

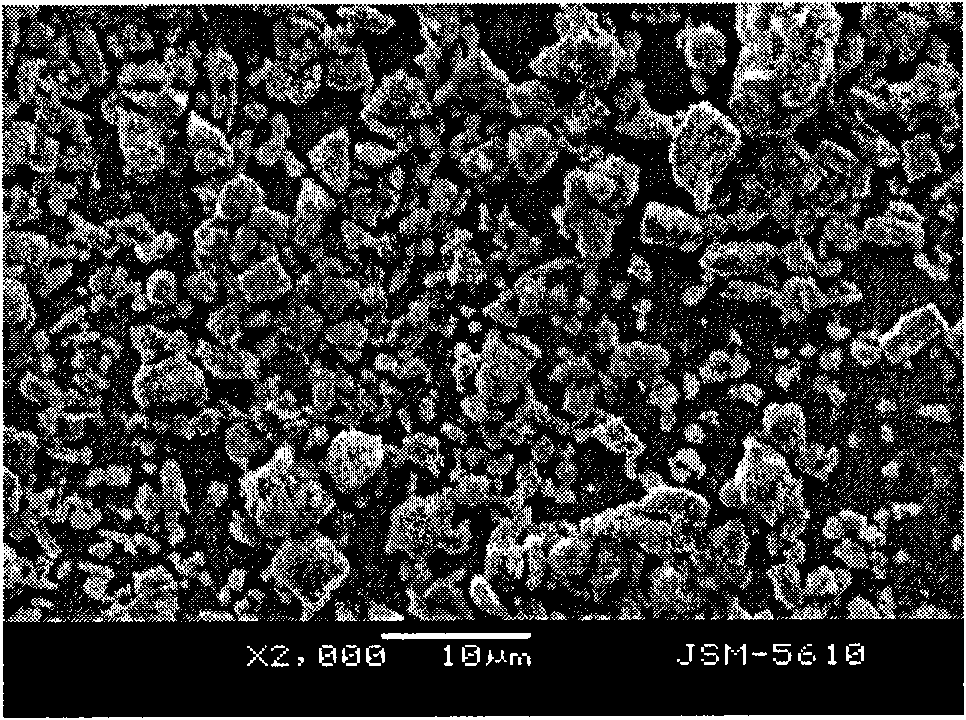

Method for preparing rare-earth vanadate LaVO4:Eu red fluorescent powder

A technology of red fluorescent powder and rare earth vanadate, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of particle crystal shape damage, adverse effects of fluorescent powder luminescent performance, etc., achieve fast synthesis speed, shorten preparation time, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 0.97mol of La 2 o 3 , 0.03mol of Eu 2 o 3 Dissolve with 3 mol of concentrated nitric acid to generate rare earth nitrate, and dilute with deionized water; weigh 2 mol of NH 4 VO 3 Make dilute solution, NH 4 VO 3 The solution was slowly added to the rare earth solution under magnetic stirring to obtain a yellow clear solution; then 1.5 moles of citric acid were added as a complexing agent; the pH value of the mixed solution was adjusted to 5 by combining dilute nitric acid and ammonia water; After fully stirring, pour the obtained emulsion into a polytetrafluoroethylene reactor, add deionized water to make the volume of the solution reach 80% of the reactor capacity (about 800ml); after sealing, place the reactor in a microwave oven , adjust the power to mid-range, microwave irradiation for 8 minutes; then the obtained suspension was centrifuged at high speed and the supernatant was poured off, the sediment was washed twice with deionized water, then washed with ab...

Embodiment 2

[0019] 0.96mol of La 2 o 3 , 0.04mol of Eu 2 o 3 Dissolve with 3 mol of concentrated nitric acid to generate rare earth nitrate, and dilute with deionized water; weigh 2 mol of NH 4 VO 3 Make dilute solution, NH 4 VO 3 The solution was slowly added to the rare earth solution under magnetic stirring to obtain a yellow clear solution; then 1.5 moles of citric acid were added as a complexing agent; the pH value of the mixed solution was adjusted to 6 by combining dilute nitric acid and ammonia water; After fully stirring, pour the obtained emulsion into a polytetrafluoroethylene reactor, add deionized water to make the volume of the solution reach 80% of the reactor capacity (about 800ml); after sealing, place the reactor in a microwave oven , adjust the power to mid-range, and irradiate with microwave for 9 minutes; then the obtained suspension is centrifuged at high speed and the supernatant is poured off, the sediment is washed twice with deionized water, washed with abs...

Embodiment 3

[0021] 0.95mol of La 2 o 3 , 0.05mol of Eu 2 o 3 Dissolve with 3 mol of concentrated nitric acid to generate rare earth nitrate, and dilute with deionized water; weigh 2 mol of NH 4 VO 3 Make dilute solution, NH 4 VO 3 The solution was slowly added to the rare earth solution under magnetic stirring to obtain a yellow clear solution; then 1.5 moles of citric acid were added as a complexing agent; the pH value of the mixed solution was adjusted to 7 by combining dilute nitric acid and ammonia water; After fully stirring, pour the obtained emulsion into a polytetrafluoroethylene reactor, add deionized water to make the volume of the solution reach 80% of the reactor capacity (about 800ml); after sealing, place the reactor in a microwave oven , adjust the power to mid-range, and irradiate with microwave for 10 minutes; then the obtained suspension is centrifuged at high speed and the supernatant is poured off, the sediment is washed twice with deionized water, washed with ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com