Method for preparing Pd doped TiO2 nanotube array composite material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

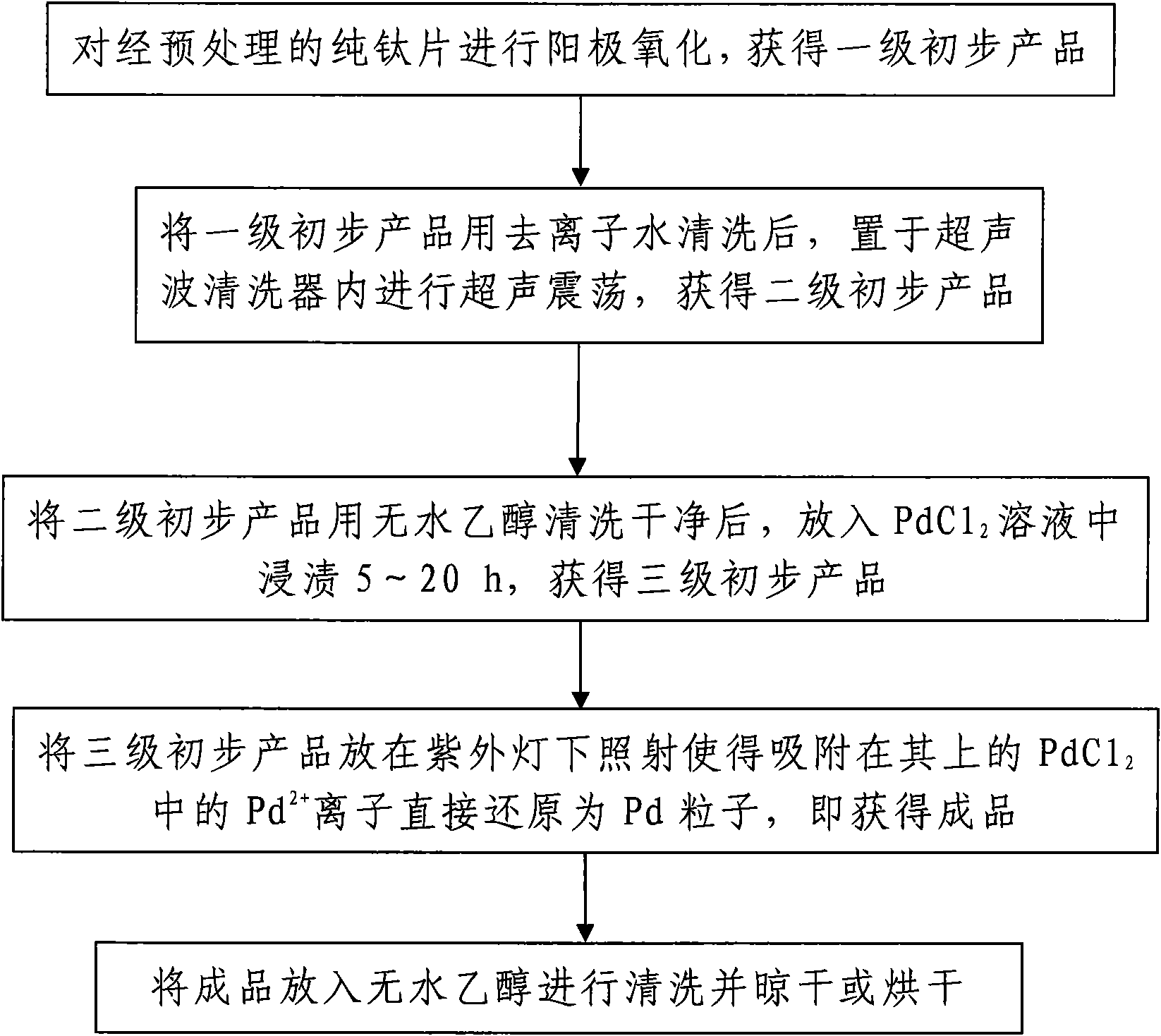

[0031] like figure 1 As shown, the Pd-doped TiO described in the present invention 2 A method for preparing a nanotube array composite material, comprising the following steps:

[0032] Step 1, anodic oxidation is carried out to the pretreated pure titanium sheet, and it comprises the following steps:

[0033] 1.1. Pretreatment of pure titanium sheet: the oxide layer on the surface of the pure titanium sheet to be treated is removed by conventional mechanical processing. The pure titanium sheet is a flat sheet with a thickness of 0.1-1.0 mm.

[0034] The pure titanium sheet is an industrial pure titanium sheet. In the actual processing process, mechanical grinding is used to remove the oxide layer on the surface of the pure titanium sheet to be processed. Specifically, 600# and 1000# water abrasive papers are used for mechanical grinding to remove the surface of the pure titanium sheet. After removing the oxide layer on the surface of the pure titanium sheet to be treated, t...

Embodiment 2

[0047] In this example, the difference from Example 1 is that the pretreated pure titanium sheet in step 1.1 is a rectangular sheet of 100 mm × 20 mm × 0.3 mm; As the cathode, the voltage of the DC power supply used is 70V, the oxidation temperature is 10-70°C and the oxidation time is 26h. When performing ultrasonic oscillation in step 2, the oscillation time is 0.2h. The power of the ultraviolet lamp described in step 4 is 200W and the irradiation time is 1h. In this embodiment, the rest of the process steps and process parameters are the same as those in Example 1.

Embodiment 3

[0049] In this embodiment, the difference from Example 1 is: the pretreated pure titanium sheet in step 1.1 is a rectangular sheet of 100 mm × 20 mm × 0.3 mm; the anhydrous organic solvent for preparing the electrolyte in step 1.2 is Ethylene glycol, the solute is NH 4 F, and the volume ratio of ethylene glycol and water is 97:3, NH 4 The mass ratio of F to the prepared electrolyte is 0.3%; in step 1.3, when the pretreated pure titanium sheet is placed in the electrolyte for anodic oxidation reaction, that is, when the electrolytic oxidation reaction is performed, the stainless steel foil electrode is used as the cathode, The voltage of the DC power supply used is 30V, the oxidation temperature is room temperature and the oxidation time is 50h. PdCl described in step 3 2 The concentration is 0.3mol / L and the soaking time is 5h. The power of the ultraviolet lamp described in step 4 is 100W and the irradiation time is 2h. In this embodiment, the rest of the process steps and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com