Low ceramet group automobile brake block and preparation method thereof

A brake pad and ceramic-based technology, applied in the field of brake pads, can solve the problems of shortened service life of brake pads, easy to produce cracks, high temperature wear performance, reduced bonding effect, etc., achieves noise control and service life improvement, and the preparation method is simple and feasible , the effect of high temperature performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with specific embodiments.

[0025] The formula description of the low cermet base brake pad provided by the invention

[0026] Ceramic binder 10~20(wt.%) Resin / rubber 5~10(wt.%)

[0027] Steel fiber 10~25(wt.%) Copper fiber, mineral fiber and aramid fiber 10~25(wt.%)

[0028] Graphite 10~15(wt.%) Antimony sulfide 3~8(wt.%)

[0029] Chromite 2~5(wt.%) Organic friction powder 2~5(wt.%)

[0030] Barite 10~20(wt.%) Petroleum coke 2~5(wt.%)

[0031] In this formula system, the ceramic binder mainly refers to the modified aluminum and silicate inorganic high-temperature binder, which can significantly improve the temperature resistance of the material, reduce the wear of the material at high temperature, and at the same time make the The material forms a porous structure, which increases braking smoothness and reduces braking noise. In order to continue to use the molding process and production equipme...

PUM

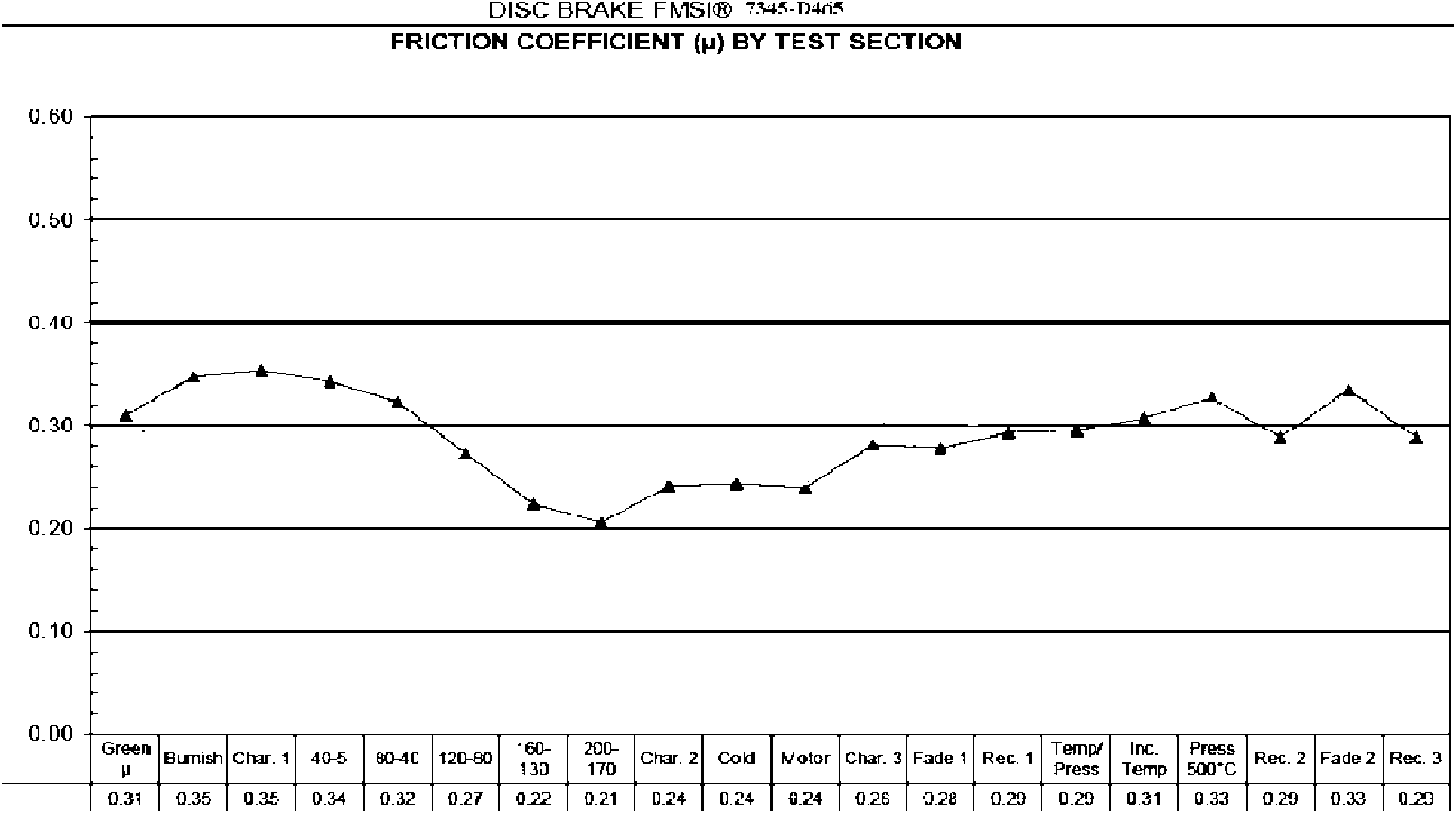

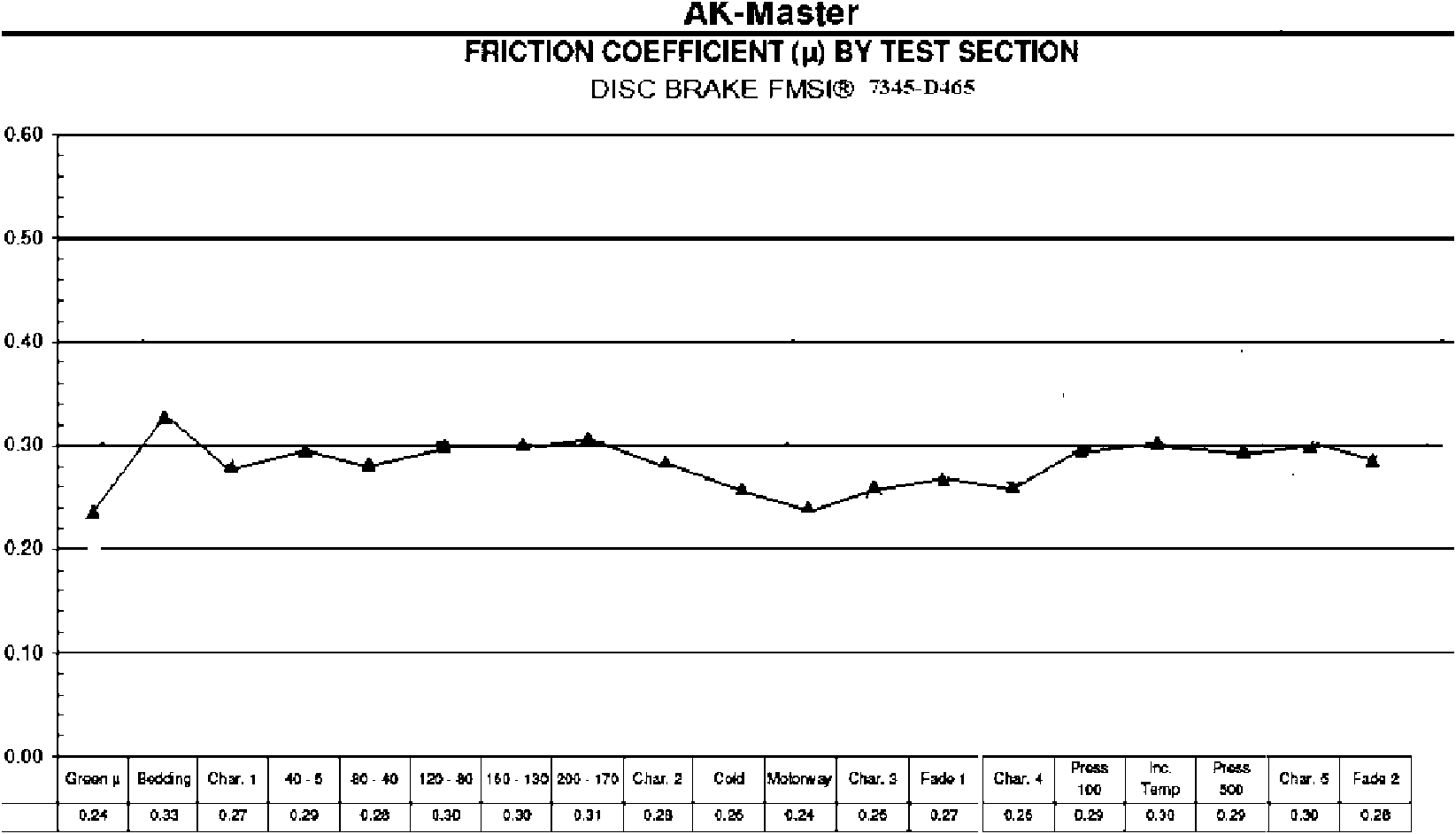

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com