Method for processing organic wastewater for manufacturing circuit board using short distance distillation

A technology of organic wastewater and short-path distillation, which is applied in the field of environmental pollution control, can solve the problems of large fixed investment, secondary air pollution, and large floor space, and achieve the effects of reducing environmental pollution, reducing implementation costs, and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

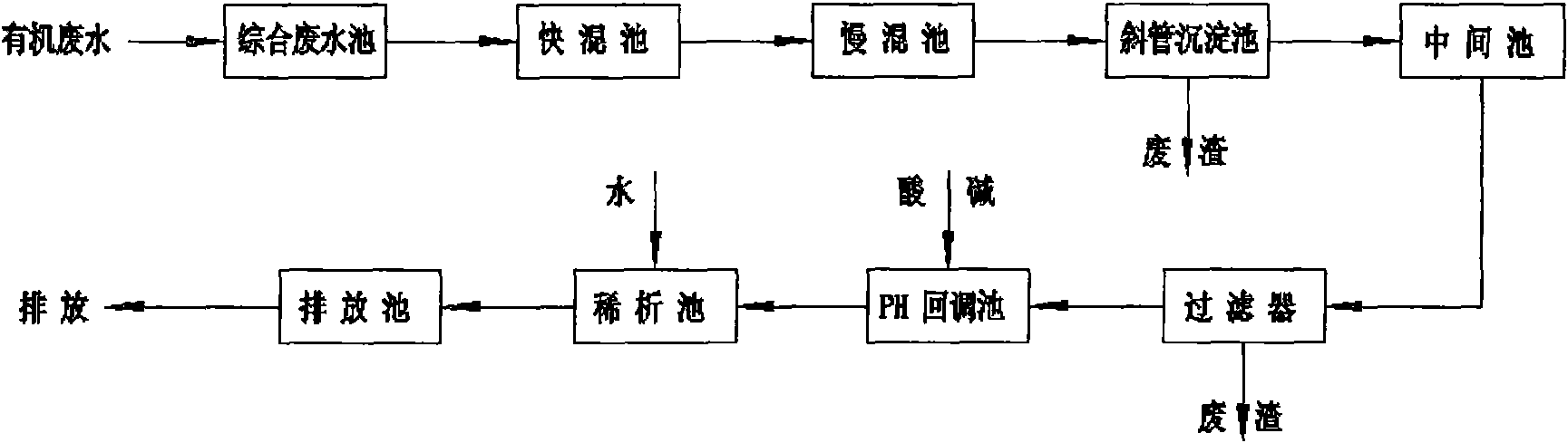

Method used

Image

Examples

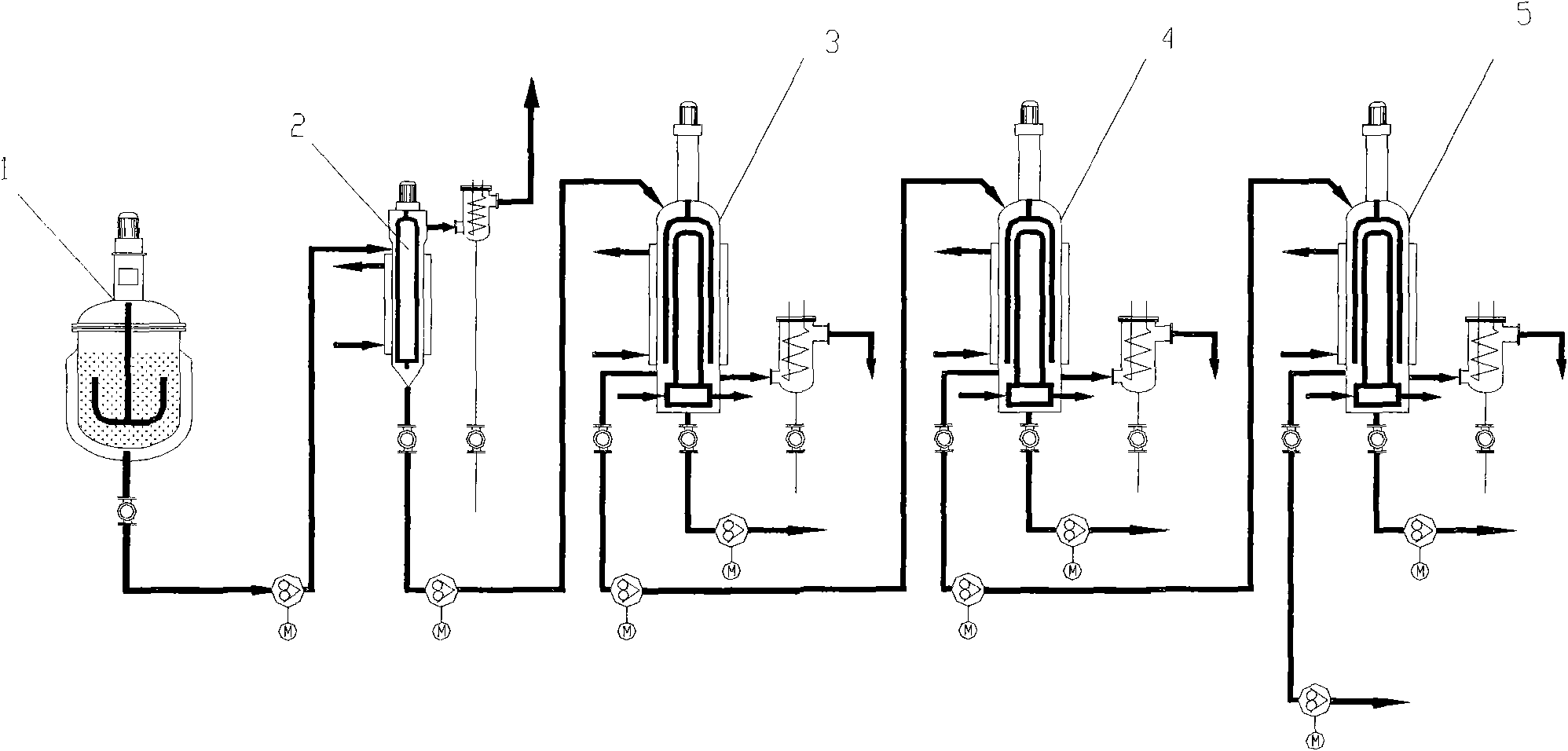

Embodiment 1

[0031] (1) Weigh 20 liters of recycled organic waste water from the circuit board manufacturing industry, its COD concentration is 18000mg / L, Cu 2+ , Sn 2+ and Pb 2+ The concentration is 100mg / L; the organic wastewater from the circuit board manufacturing industry is directly sent to the buffer tank 1, and the metering pump is input to the first-stage short-range evaporator 2 for concentration and dehydration. The temperature is 60°C and the pressure is -0.6Mpa. Carry out the first concentration and dehydration, the weight of separated water is 9 liters, and its COD content is 80mg / L. After concentration and dehydration, the organic wastewater from the circuit board manufacturing industry continues to enter the next short-path distillation column for separation.

[0032] (2) The dehydrated organic waste water from the circuit board manufacturing industry is pumped into the second-stage short-path distillation column 3 to continue to concentrate and separate part of the water...

Embodiment 2

[0034] (1) 50 liters of organic wastewater from the circuit board manufacturing industry was recovered from a certain time, the COD concentration was 25000mg / L, Cu 2+ , Sn 2+ and Pb 2+ The concentration is 120mg / L. The organic waste water from the circuit board manufacturing industry is directly sent to the buffer tank 1, and the metering pump is input to the first-stage short-range evaporator 2 for concentration and dehydration, specifically at a temperature of 40°C and a pressure of -0.6Mpa. Carry out the first concentrated dehydration. The weight of the separated water is about 8 liters, and its COD content is 98mg / L.

[0035] (2) The dehydrated organic wastewater from the circuit board manufacturing industry is pumped into the second-stage short-path distillation column 3 to separate the middle part of the water, specifically at a temperature of 70°C and a pressure of -0.6Mpa. Concentrated and dehydrated. The weight of the separated water is about 20 liters, and its CO...

Embodiment 3

[0038] (1) Measure 50 liters of organic waste water recycled from the circuit board manufacturing industry, its COD concentration is 18000mg / L, Cu 2+ , Sn 2+ and Pb 2+The concentration is 120mg / L. The organic waste water from the circuit board manufacturing industry is directly sent to the buffer tank 1, and the metering pump is input to the first-stage short-range evaporator 2 for dehydration, specifically at a temperature of 80°C and a pressure of -0.3Mpa. Conditions for the first concentration dehydration. The weight of the separated water is about 9 liters, and its COD concentration is 96mg / L.

[0039] (2) After dehydration, the organic wastewater from the circuit board manufacturing industry is pumped into the second-stage short-path distillation column 3 to separate the middle part of the water, specifically at a temperature of 85°C and a pressure of -0.5Mpa. Carry out the second concentrated dehydration. The weight of the separated water is about 12 liters, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com