Method for separating and purifying plant ice structural protein

An ice structure protein, separation and purification technology, applied in the field of food additive separation, can solve the problems of high cost, unable to maintain a reasonable price, loss of antifreeze activity, long separation cycle, etc. The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

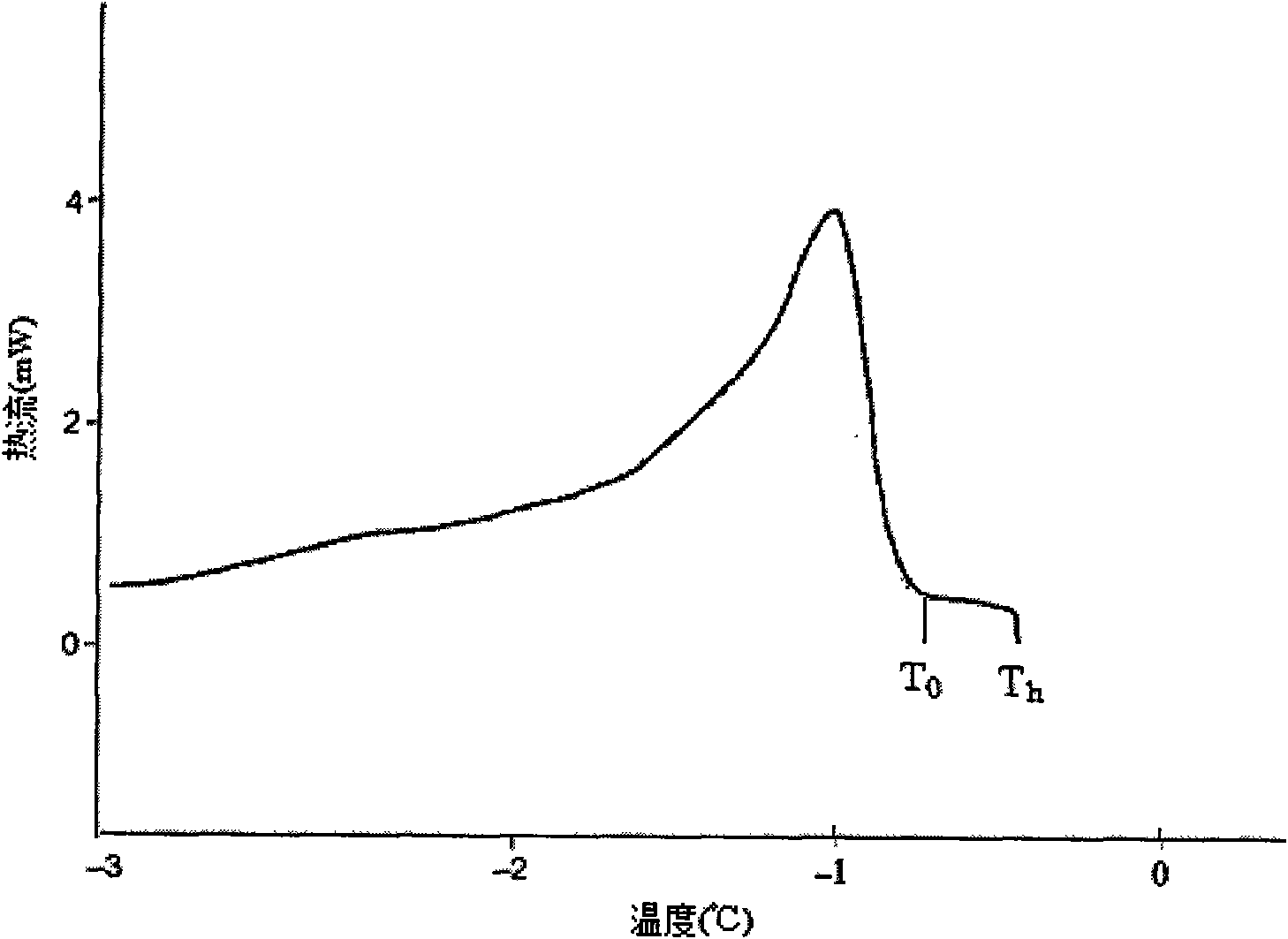

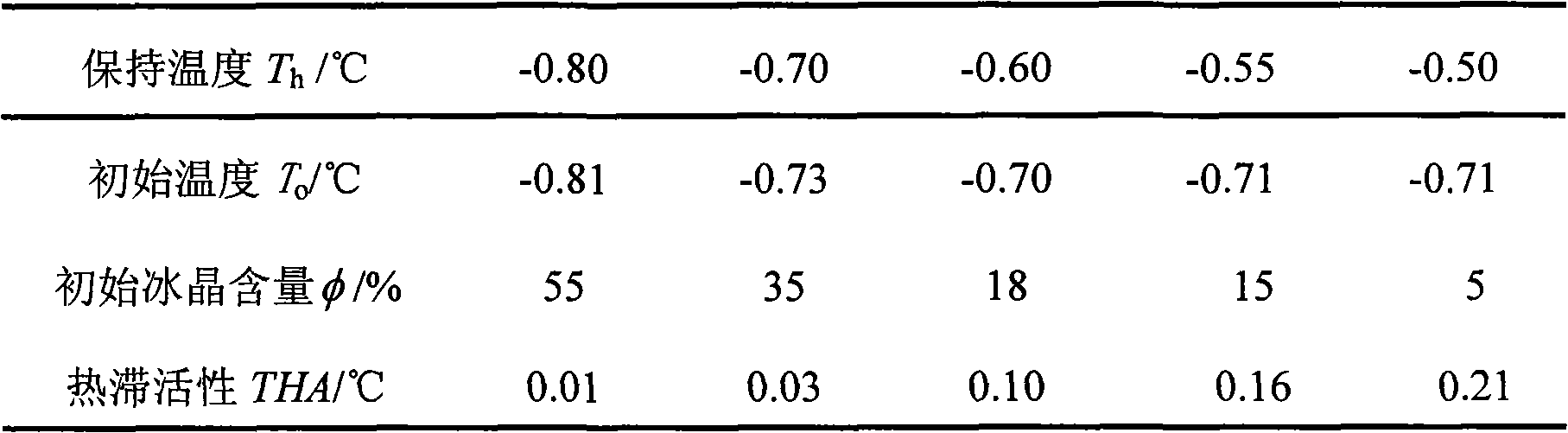

[0021] Weigh 100 g of pulverized winter wheat, add 1000 mL of phosphate buffer solution (100 mM, pH 7.3) containing 0.5% Genapol X-080 (fatty alcohol polyoxyethylene ethers, purchased from Sigma-Aldrich Company), and soak for 1 hour Filtrate to obtain the leach solution of solid filter residue and ice-structural protein; continue to add Genapol X-080 to 5% to the ice-structural protein leach solution, then heat to 50°C for phase-separation extraction, centrifuge at 5000rpm for 10min after 2h, and separate Take out the water phase; take the water phase solution and place it in a dialysis bag with a molecular weight cut-off of 6000 Da, and fully dialyze at 4°C. After dialysis, use polyethylene glycol 10,000 to cover and concentrate the dialysis bag, concentrate to 1 / 20 of the original volume, and then freeze After drying, 2.8 g of the isolated and purified ice structural protein sample was obtained. Accurately weigh 0.5 g of the above ice-structured protein sample, dissolve it i...

Embodiment 2

[0025] Weigh 100 g of crushed winter wheat, add 1000 mL of phosphate buffer solution (100 mM, pH 7.3) containing 1% Triton X-114 (alkylphenol polyoxyethylene ethers, purchased from Shanghai Jingchun Reagent Co., Ltd.), and extract Filter after 1 hour to obtain the solid filter residue and the leach solution of ice-structural protein, continue to supplement Triton X-114 to 3% in the ice-structural protein leach solution, then heat to 35°C for phase-separation extraction, centrifuge at 5000rpm after 2h After 10 minutes, the water phase was separated, and the water phase solution was placed in a dialysis bag with a molecular weight cut-off of 6000 Da, and fully dialyzed at 4°C. After dialysis, the dialysis bag was covered and concentrated with polyethylene glycol 10,000, and concentrated to 1 / 20 of the original volume. Freeze-drying was then carried out to obtain 3.5 g of the isolated and purified ice-structural protein sample. Accurately weigh 0.5 g of the above ice-structured p...

Embodiment 3

[0029]Take pulverized winter privet leaves 100g, add 1000mL containing 0.5% Genapol X-080 (fatty alcohol polyoxyethylene ethers, purchased from Sigma-Aldrich company) phosphate buffer solution (100mM, pH 7.3), leaching Filtrate after 2 hours to obtain the solid filter residue and the leach solution of ice-structural protein; continue to supplement Genapol X-080 to 5% in the ice-structural protein leach solution, then heat to 50°C for phase-separation extraction, and centrifuge at 5000rpm after 2h After 10 minutes, the aqueous phase was separated; the aqueous phase solution was placed in a dialysis bag with a molecular weight cut-off of 6000 Da, and fully dialyzed at 4°C. After dialysis, the dialysis bag was covered and concentrated with polyethylene glycol 10,000, and concentrated to 1 / 20 of the original volume. Freeze-drying was then carried out to obtain 1.8 g of the isolated and purified ice-structural protein sample. Accurately weigh 0.5 g of the above ice-structured prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com