Method for preparing carbon nanotube grafted with vinyl macromolecular chain on the surface

A carbon nanotube and vinyl technology, applied in the field of carbon nanomaterial preparation, can solve the problems of complex process, heavy pollution, difficult dispersion of CNTs, etc., and achieve the effect of simple process, low cost, excellent oil solubility or water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

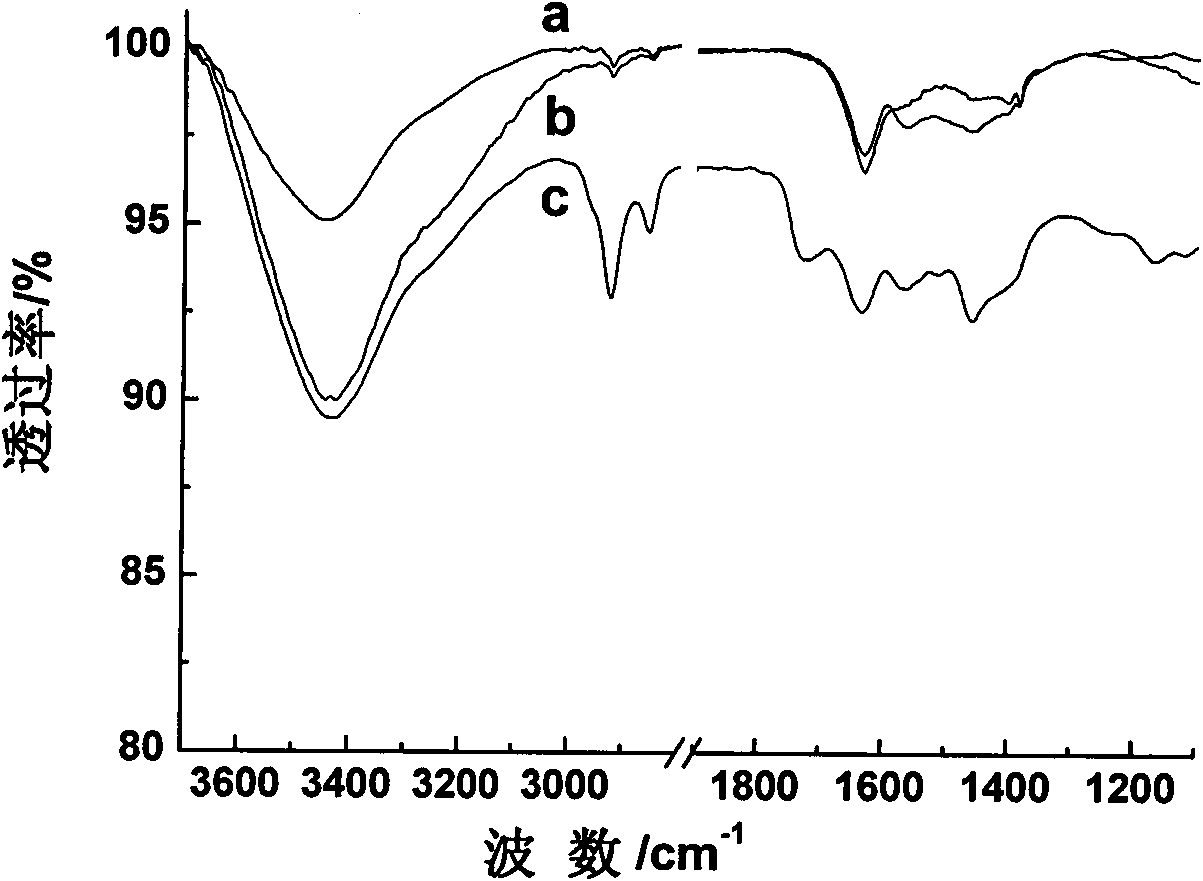

[0025] 1. Mix 1 part by weight of multi-walled carbon nanotubes with a diameter of 0.5 nm and a length of 0.1 um with 100 parts by weight of ferrous chloride aqueous solution with a concentration of 0.5 mol / L, and use ultrasonic dispersion treatment for 0.5 h , then further add 10 parts of hydrogen peroxide dropwise while stirring, and continue to react for 1 h after the dropwise addition, after filtering, fully washing with pure water, drying, and grinding to obtain surface hydroxylated carbon nanotubes, its infrared spectrum is shown in figure 1 -b;

[0026] 2. Mix 1 part by weight of the carbon nanotubes obtained in the first step with 10 parts by weight of ethanol and 1 part by weight of KH570 silane coupling agent, stir and ultrasonically disperse for 0.5h, then filter and fully wash with acetone reagent , drying, and grinding to obtain surface coupling agent functionalized carbon nanotubes;

[0027] 3. Mix 1 part by weight of the carbon nanotubes obtained in the second ...

Embodiment 2

[0029]1. 1 part by weight of a purified tube diameter of 200nm and a length of 100um multi-walled carbon nanotubes is mixed with 10 parts by weight of ferrous chloride aqueous solution of 10mol / L concentration, treated with ultrasonic dispersion for 12h, and further Add 100 parts of hydrogen peroxide dropwise while stirring, continue to react for 8 hours after the dropwise addition, filter, fully wash with pure water, dry, and grind to obtain surface hydroxylated carbon nanotubes;

[0030] 2. Mix 1 part by weight of the carbon nanotubes obtained in the first step with 1000 parts by weight of acetone and 0.01 part by weight of isopropyltriacryloyl titanate, stir and ultrasonically disperse for 12 hours, and then filter and wash with acetone The reagents are fully washed, dried, and ground to obtain surface coupling agent functionalized carbon nanotubes;

[0031] 3. Mix 1 weight part of the carbon nanotubes obtained in the second step with 1000 weight parts of xylene and 1 weigh...

Embodiment 3

[0033] 1. 1 part by weight of a purified tube diameter of 20-40nm and a length of 5-15um single-walled carbon nanotubes is mixed with 50 parts by weight of an aqueous solution of ferrous sulfate of 1mol / L concentration, and treated with ultrasonic dispersion for 1h. Further add 50 parts of hydrogen peroxide dropwise while stirring, continue to react for 1 hour after the dropwise addition, filter, fully wash with pure water, dry, and grind to obtain surface hydroxylated carbon nanotubes;

[0034] 2. Mix 1 part by weight of the carbon nanotubes obtained in the first step with 100 parts by weight of methyl ethyl ketone and 1 part by weight of DL-414 aluminate coupling agent, stir and ultrasonically disperse for 2 hours, and further filter and use The acetone reagent is fully washed, dried, and ground to obtain surface coupling agent functionalized carbon nanotubes;

[0035] 3. Mix 1 part by weight of the carbon nanotubes obtained in the second step with 50 parts by weight of benz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com