Germanate glass luminescent film and preparation method

A technology of germanate glass and glass film, which is applied in the field of germanate luminescent glass film and its preparation, and can solve the problems of unfavorable production of high-performance luminescent materials, poor composition uniformity, and no requirement for material form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

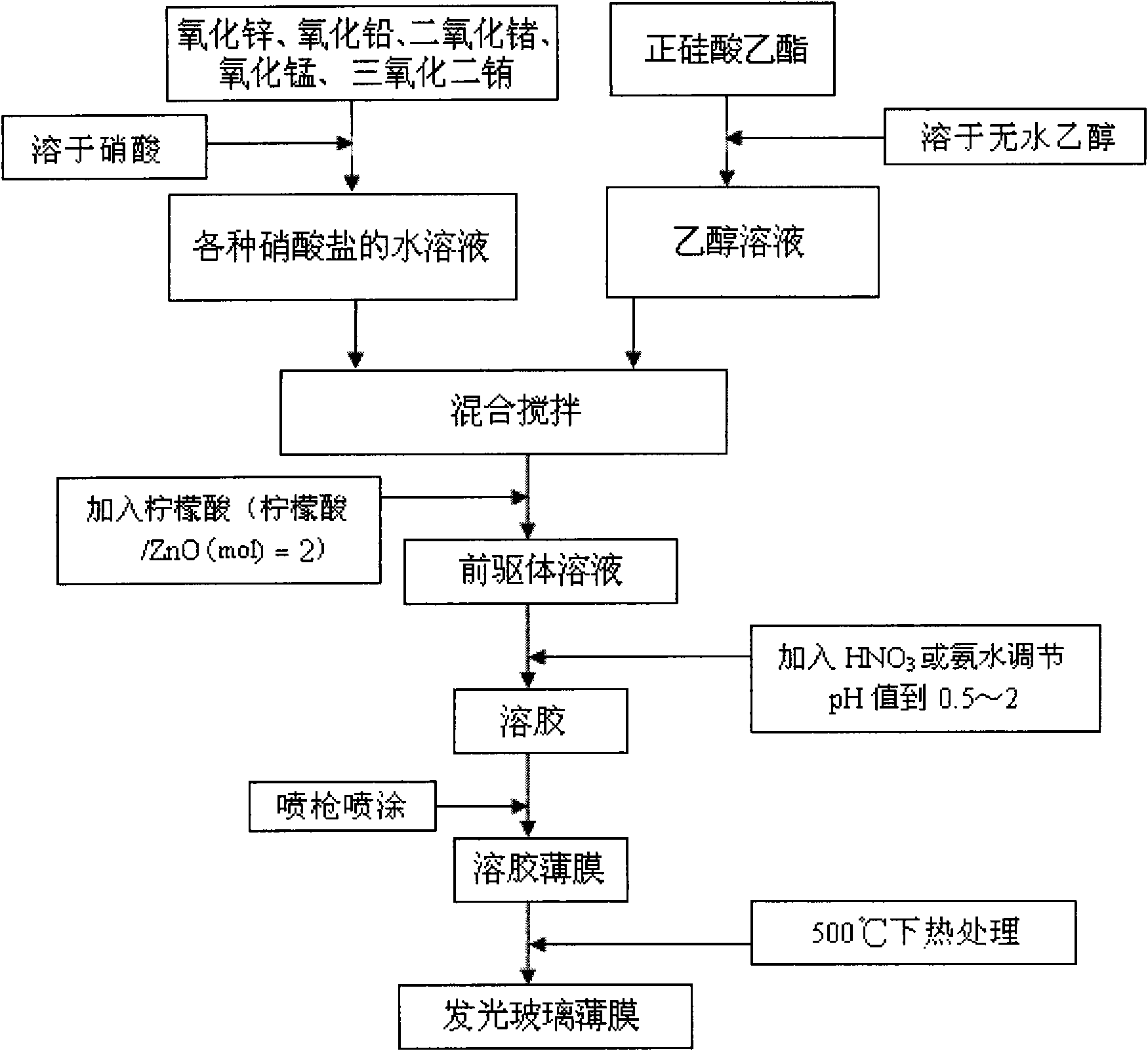

Method used

Image

Examples

example 1

[0012] The molar percentage composition of the glass film is: 30% of zinc oxide; 20% of lead oxide; 40% of germanium dioxide; 4.9% of silicon oxide, 0.1% of manganese oxide and 5% of europium trioxide. Dissolve zinc oxide, lead oxide, germanium dioxide, manganese oxide, and europium trioxide in nitric acid to make a 0.5mol / L nitrate solution, and dissolve ethyl orthosilicate in anhydrous Ethanol, mix various solutions according to the proportion, and add a certain amount of citric acid (according to citric acid: metal ion = 2: 1) as a chelating agent. Mix the prepared mixed solution with a magnetic stirrer, adjust the pH value to 1, make a sol and pour it into an atomizing container for use. Quartz glass is used as the substrate in the preparation. After being kept in a heating furnace at 500°C for 1 hour, the sol is pressurized by a pressure pump and enters the spray gun. After being atomized by high-pressure gas at the nozzle of the spray gun, it deposits on the high-tempera...

example 2

[0014] The molar percentage composition of the glass film is: 25% of zinc oxide; 20% of lead oxide; 40% of germanium dioxide; 9.9% of silicon oxide, 0.1% of manganese oxide and 5% of europium trioxide. Dissolve zinc oxide, lead oxide, germanium dioxide, manganese oxide, and europium trioxide in nitric acid to make a 1mol / L nitrate solution, and dissolve ethyl orthosilicate in absolute ethanol at a volume ratio of 1:1 , mix the various solutions according to the proportion, and add a certain amount of citric acid (according to citric acid: metal ion = 2: 1) as a chelating agent. Mix the prepared mixed solution with a magnetic stirrer, adjust the pH value to 1, make a sol and pour it into an atomizing container for use. Quartz glass is used as the substrate in the preparation. After being kept in a heating furnace at 500°C for 1 hour, the sol is pressurized by a pressure pump and enters the spray gun. After being atomized by high-pressure gas at the nozzle of the spray gun, it d...

example 3

[0016] The molar percentage composition of the glass film is: 40% of zinc oxide; 10% of lead oxide; 40% of germanium dioxide; 14.9% of silicon oxide, 0.1% of manganese oxide and 5% of europium trioxide. Dissolve zinc oxide, lead oxide, germanium dioxide, manganese oxide, and europium trioxide in nitric acid to make a 0.5mol / L nitric acid solution, and dissolve ethyl orthosilicate in absolute ethanol at a volume ratio of 1:1 , mix the various solutions according to the proportion, and add a certain amount of citric acid (according to citric acid: metal ion = 2: 1) as a chelating agent. Mix the prepared mixed solution with a magnetic stirrer, adjust the pH value to 1, make a sol and pour it into an atomizing container for use. Quartz glass is used as the substrate in the preparation. After being kept in a heating furnace at 500°C for 1 hour, the sol is pressurized by a pressure pump and enters the spray gun. After being atomized by high-pressure gas at the nozzle of the spray gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com