Method for plating surface of rhinestone and plastic-suction disk

A rhinestone and plating technology, applied in metal material coating technology, jewelry, coating, etc., to improve processing efficiency, ensure product quality, and reduce the difficulty of workshop management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

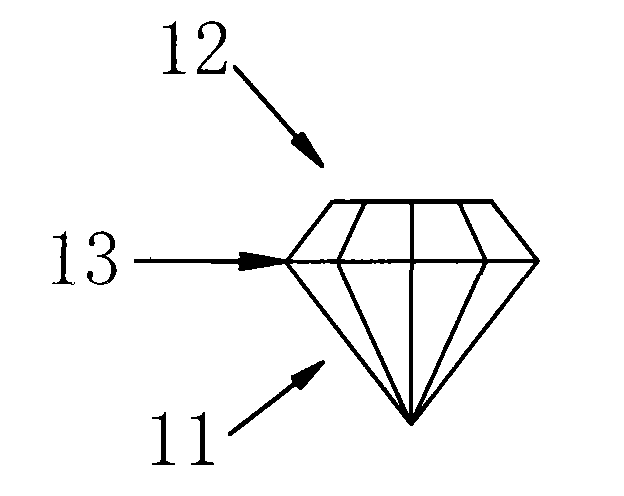

[0041] A rhinestone surface coating method, the steps are as follows:

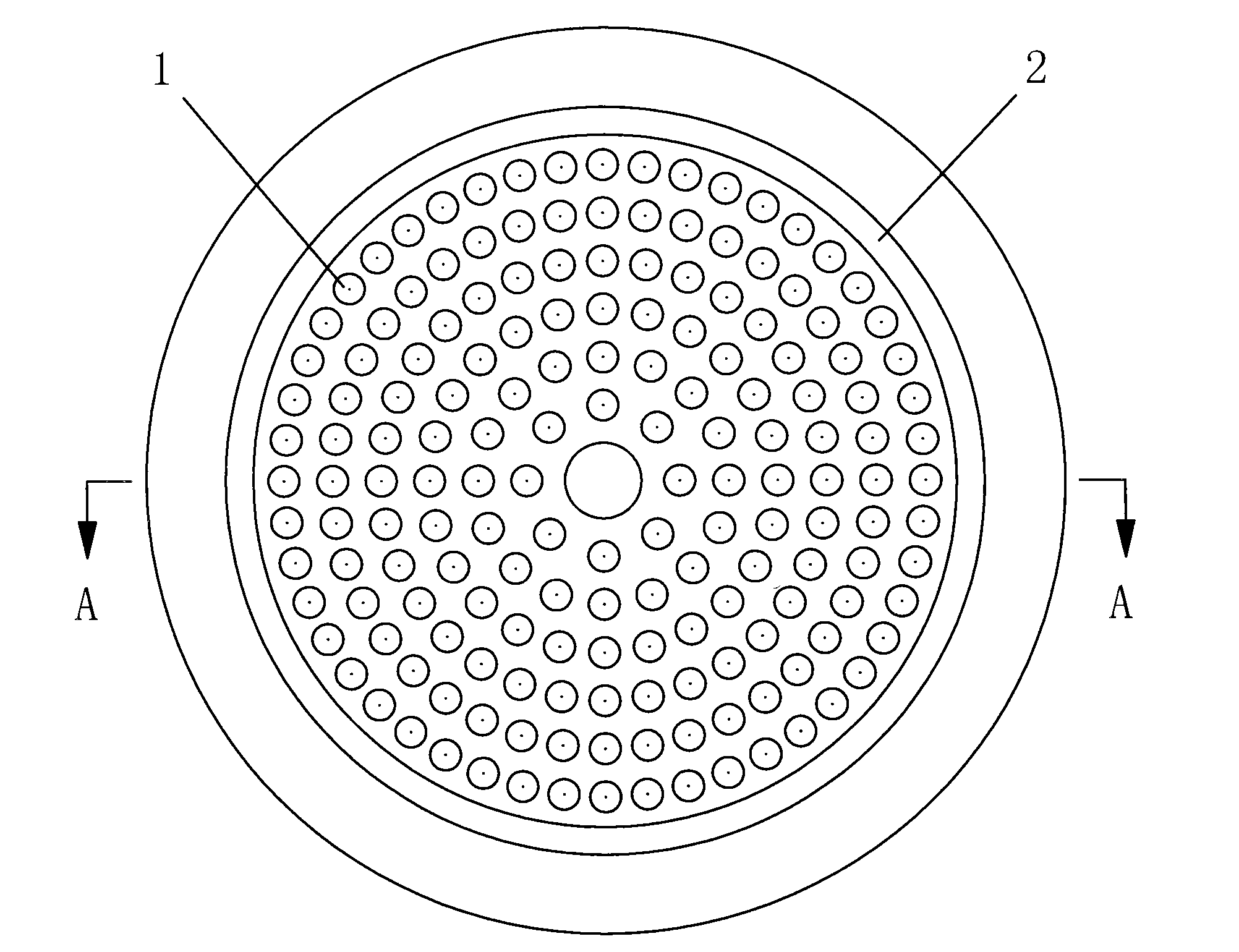

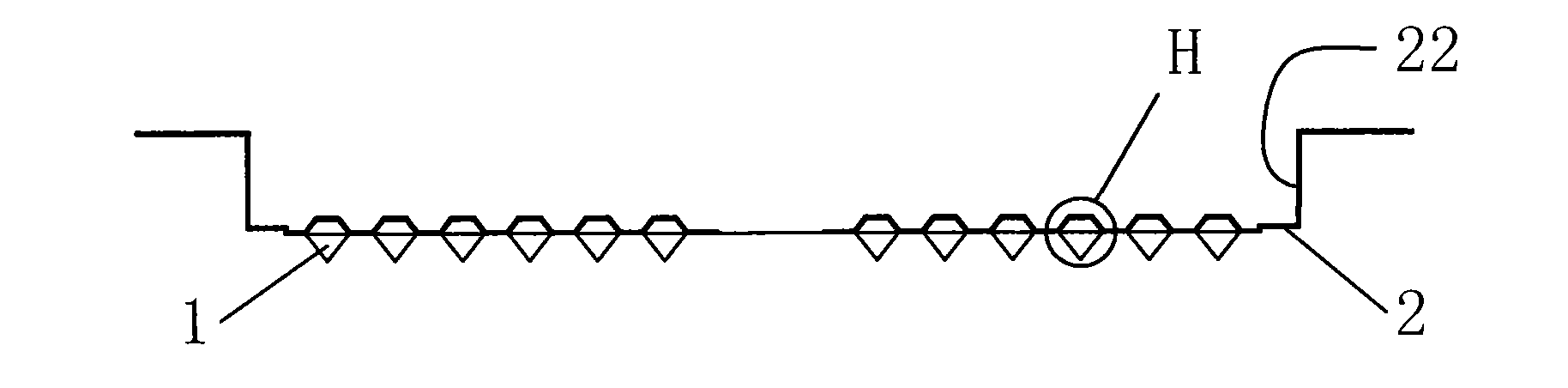

[0042] 1) Arrange a plurality of rhinestones 1 in the same direction and form them into a blister tray 2 through blister molding, such as Figure 2~4 As shown, a plurality of adsorption holes 21 matching the face of the rhinestone 1 are formed on one surface of the blister tray 2, and the face of the rhinestone 1 is embedded in the adsorption hole 21 and fixed;

[0043] 2) A reflective layer 14 is coated on one side of the blister tray 2 inlaid with rhinestones 1, and the reflective layer 14 is a silver layer;

[0044] 3) A protective layer 15 is applied to the side of the blister tray 2 coated with the reflective layer 14, and the protective layer 15 is an anti-tarnish paint layer;

[0045] 4) Separate the rhinestone 1 from the blister tray 2 and take it out.

[0046] In this embodiment, in the above step 1, a plurality of rhinestones 1 are first arranged on the surface of the tooling plate A4 through the...

Embodiment 2

[0049] A rhinestone surface coating method, the steps are as follows:

[0050] 1) A plurality of rhinestones 1 are arranged in the same direction and formed into a blister tray 2 through blister molding, and one surface of the blister tray 2 is formed with a plurality of adsorption holes 21 that match the face of the rhinestone 1, The face of the rhinestone 1 is embedded in the adsorption hole 21 and fixed;

[0051] 2) A reflective layer 14 is coated on one side of the blister tray 2 inlaid with rhinestones 1, and the reflective layer 14 is an aluminum layer or a chrome layer;

[0052] 3) Coating a protective layer 15 on one side of the blister tray 2 coated with the reflective layer 14, the protective layer 15 is a copper layer or a copper-zinc alloy layer;

[0053] 4) Separate the rhinestone 1 from the blister tray 2 and take it out.

[0054] In this embodiment, the blister disc used in the grinding and polishing of the end face is continued, that is, the grinding and poli...

Embodiment 3

[0056] Such as Figure 9 , Figure 10 , Figure 11 As shown in a blister tray, one of the blister tray 2 is provided with a plurality of adsorption holes 21 that match the face of the rhinestone 1, and the adsorption holes 21 are inlaid with rhinestones 1, and the face of the rhinestone 1 is embedded The suction hole 21 is fixed; the side of the blister tray 2 inlaid with the rhinestone 1 is coated with a reflective layer, and the reflective layer is a silver layer, an aluminum layer or a chrome layer. The reflective layer is coated with a protective layer, and the protective layer is an anti-tarnish paint layer, a copper layer or a copper-zinc alloy layer. The junction 13 of the face and bottom of the rhinestone 1 is embedded in the adsorption hole 21 of the blister tray 2 by 0.05-0.2mm (that is, the plastic layer of the blister tray completely covers the junction of the face and the bottom of the rhinestone and extends downward to cover 0.05~0.2mm). The adsorption holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com