Vacuum rush gum forming method of fiber-reinforced resin matrix compound material

A fiber-reinforced resin and composite material technology, applied in the field of composite material molding, can solve the problems of difficult to make barb-shaped products, difficult to ensure the regularity of lines, twisting and deformation of fiber lines, etc., to achieve high production efficiency and reduce material costs. , the effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

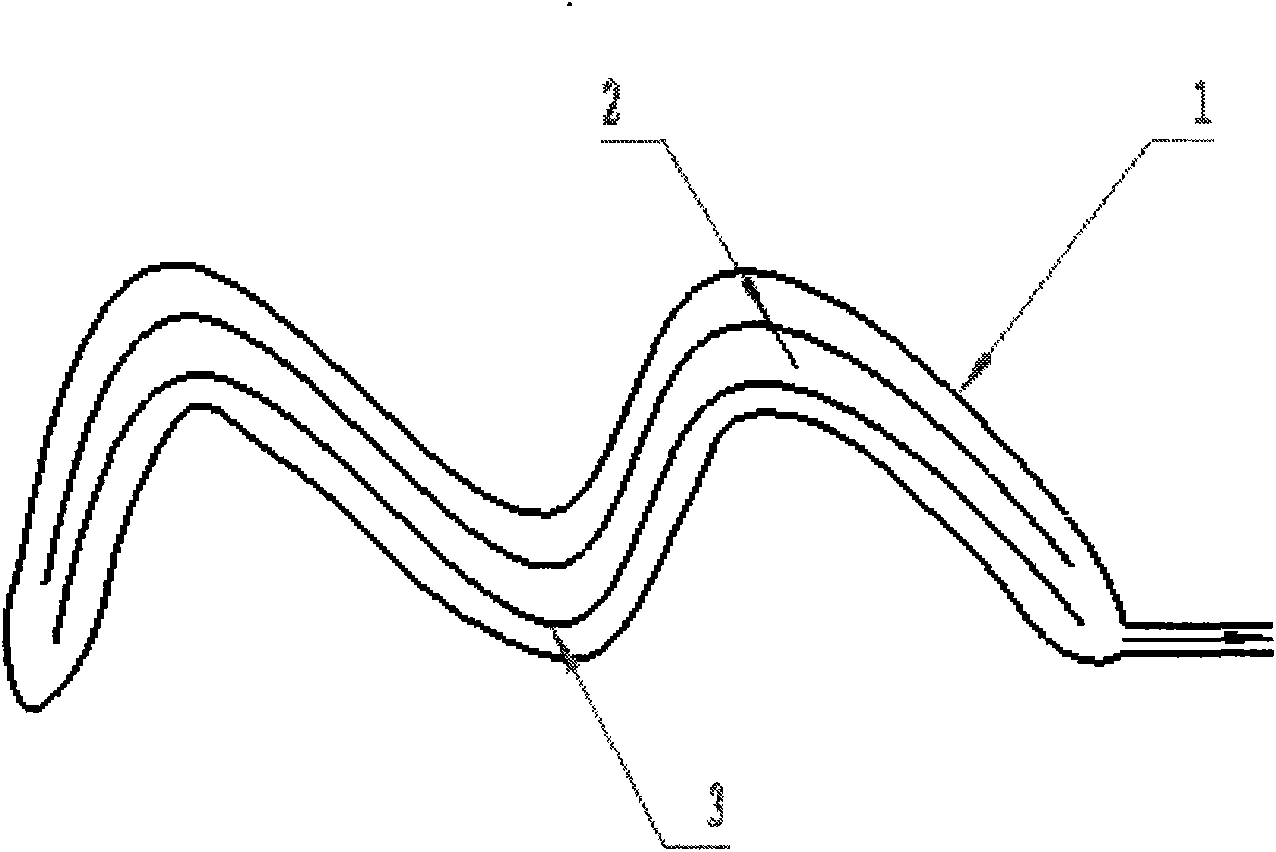

Image

Examples

Embodiment 1

[0028] Embodiment 1 The molding of carbon fiber automobile engine cover

[0029] (1) Mold preparation. The mold used for molding is a glass fiber reinforced plastic mold. First, clean up the residual glue residue in the mold cavity, dip the release agent with clean cotton yarn, and wipe it on the surface of the mold cavity.

[0030] (2) Cutting and placement of reinforcement materials. The reinforcing material is 200 g / m2 of 3K carbon fiber cloth, purchased from BGF Company of the United States, 450 g / m2 of alkali-free glass fiber chopped strand mat and 300 g / m2 of alkali-free glass fiber chopped strand mat, all purchased from Shandong Taian Glass Fiber Co., Ltd. Cut the carbon fiber cloth and fiberglass mat to size according to the mold size. The perimeter should extend 3 cm beyond the edge of the mold cavity. The first layer is 3K carbon fiber cloth, the second layer is 300 g / m2 glass fiber mat, and the third layer is 450 g / m2 glass fiber mat.

[0031] (3) With glue. ...

example 2

[0034] Example 2 Forming of carbon fiber motorcycle fender

[0035]The materials of vacuum glue forming carbon fiber motorcycle fender are as follows: 1. 600 grams of resin system, wherein the unsaturated polyester resin is LY-199 produced by Guangdong Panyu Futian Chemical Co., Ltd., the curing agent is methyl ethyl ketone peroxide, and the accelerator is 6% cobalt benzene solution, and the weight ratio is: 100: 2: 0.5;2. The reinforcement material is 1 layer of 240 g / m2 3K carbon fiber cloth, produced by Japan TORAY Company; 4 layers of 400 g / m2 alkali-free glass fiber cloth, purchased from Guangzhou Bohao Composite Materials Co., Ltd.

[0036] First, cut a piece of paper according to the motorcycle model, and its perimeter should be 3 cm larger than the fender. Cut carbon cloth and fiberglass cloth according to the pattern. Then lay it in the fender mold made of fiberglass. Pour the weighed accelerator into LV-199, stir evenly, then pour methyl ethyl ketone peroxide, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com