Method of producing enterodiol and enterolactone

A technology of enterodiol and enterolactone, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of inability to produce enterodiol and enterolactone on a large scale, environmental pollution, and high cost of chemical synthesis methods problems, to achieve the effects of low production cost, no environmental pollution, and important scientific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

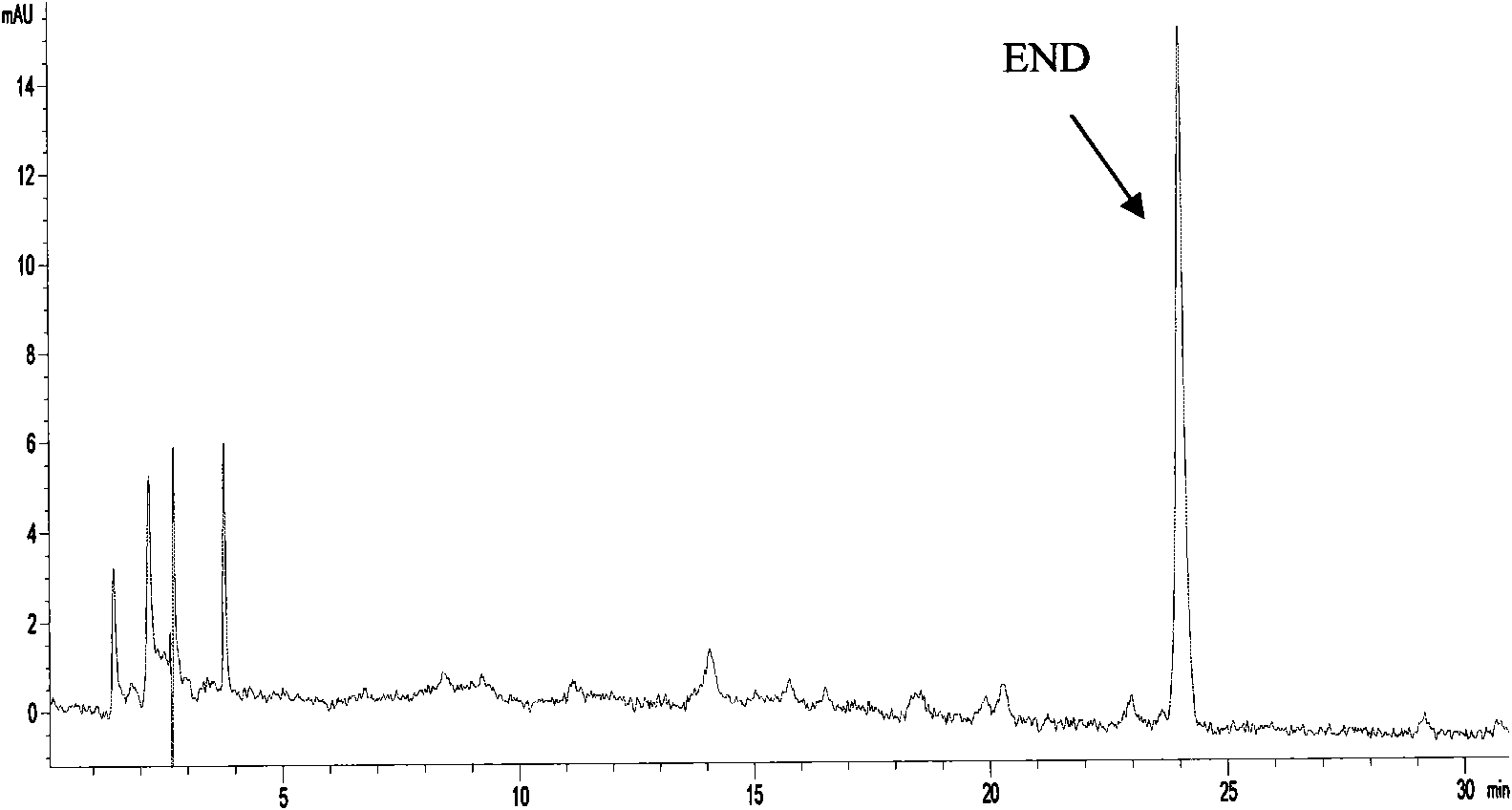

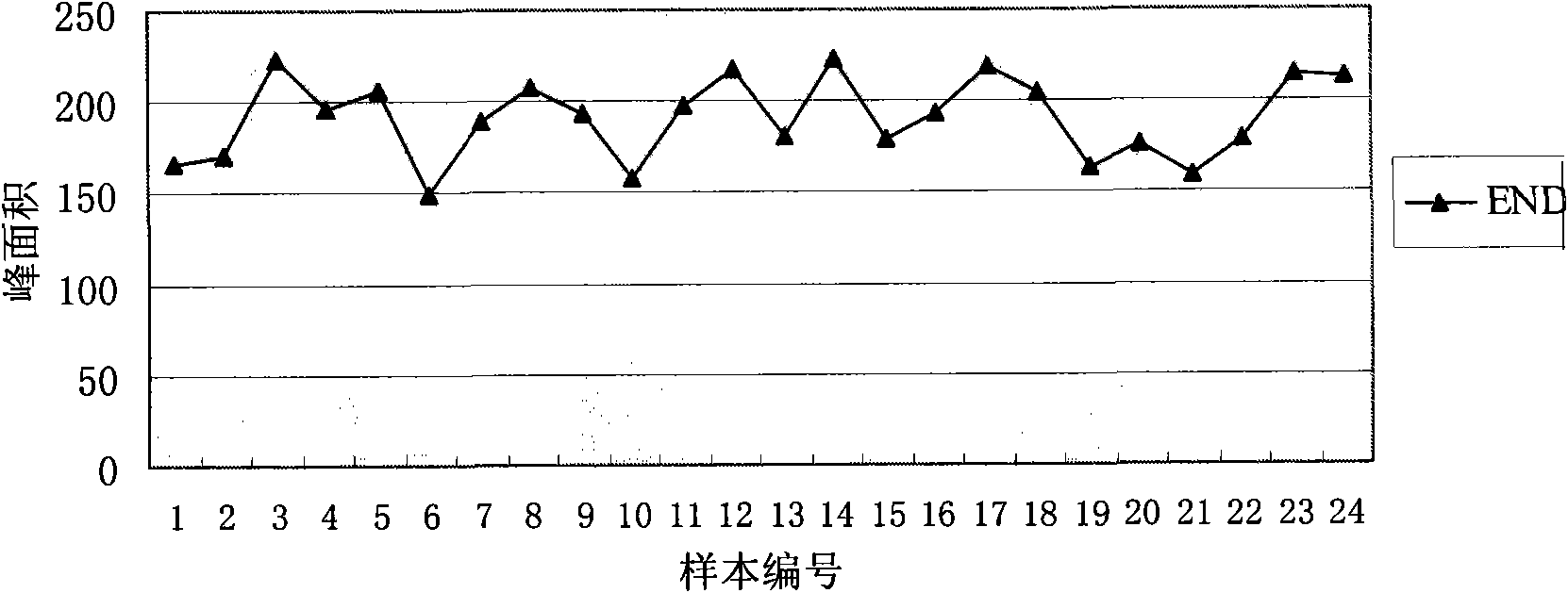

[0030] Example 1. Biotransformation of linseed meal by intestinal bacteria from different human individuals

[0031] 1. Anaerobic medium

[0032] Anaerobic medium (CM605, purchased from Beijing Luqiao Technology Co., Ltd.), its composition is as follows:

[0033] Beef infusion (1000mL); peptone (30g); yeast extract (5g); sodium dihydrogen phosphate (5g); glucose (3g); soluble starch (2g).

[0034] Prepare according to the instructions of the reagent, minced meat slag 5-30g / liter, autoclave at 121°C for 15min.

[0035] 2. Biotransformation

[0036] 1) Take fresh feces from 24 healthy people (see Table 1) and add them to phosphate buffer (pH 7.4) respectively to obtain 24 bacteria solutions with a final concentration of 4g feces / 20mL phosphate buffer.

[0037] 2) Inoculate the 24 kinds of bacterial solutions obtained in step 1 into the anaerobic medium at a ratio of 1:10, and inoculate anaerobically at 37°C (oxygen partial pressure is 3.03975kPa) for 36 hours to enrich the ba...

Embodiment 2

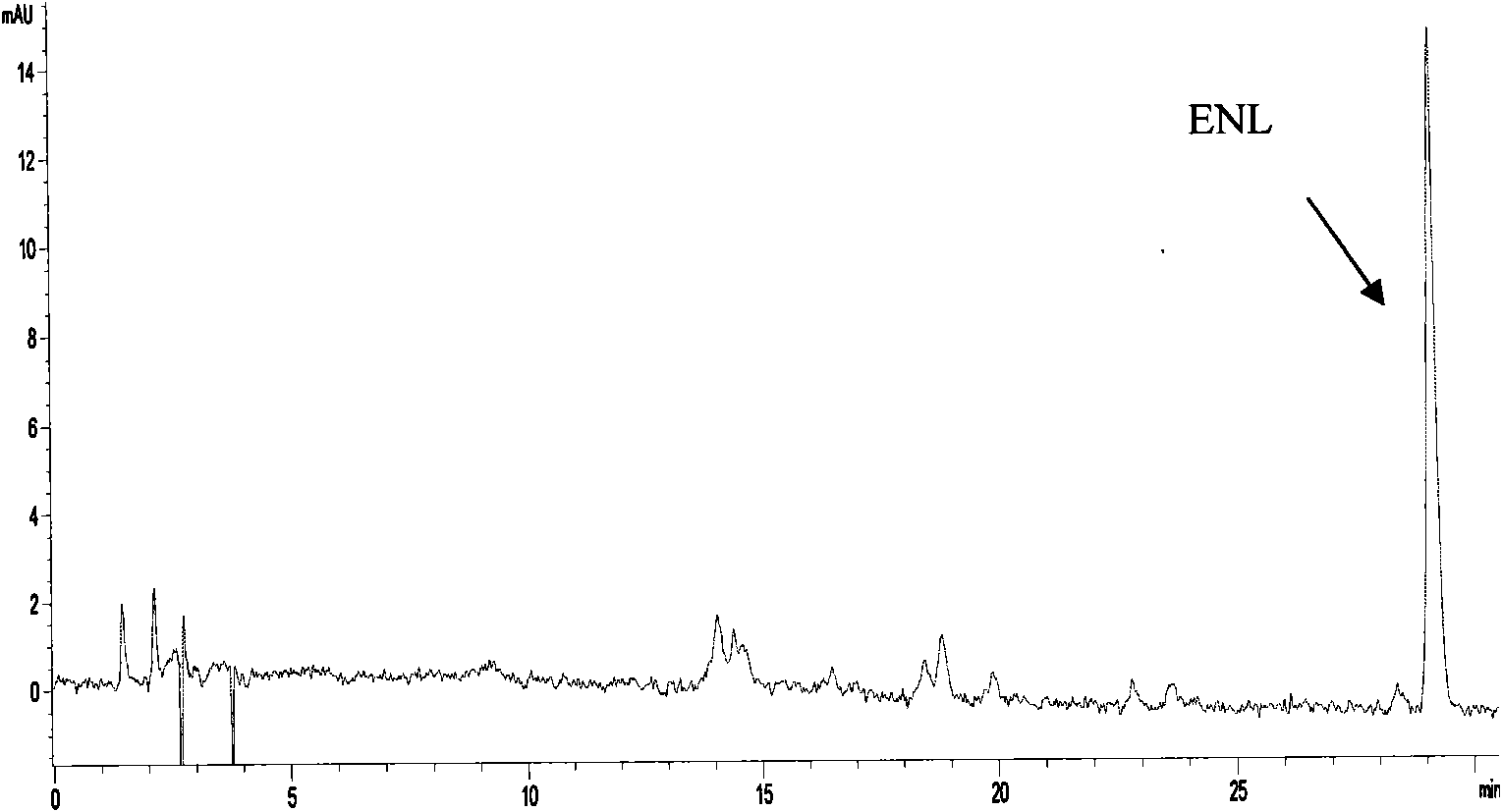

[0045] Example 2: Transformation of linseed meal from human intestinal bacteria liquid

[0046] 1. Prepare culture medium

[0047] 1) Anaerobic medium

[0048] GAM broth medium (Nissui Co., Tokyo, Japan), its composition is as follows:

[0049] 3 grams of soybean peptone; 10 grams of peptone; 13.5 grams of digestive serum powder; 5 grams of yeast extract; 2.2 grams of beef extract; 1.2 grams of bovine liver extract (powder); 3 grams of glucose; KH 2 PO 4 2.5 grams; 5 grams of soluble starch; 0.3 grams of L-cysteine salt; 0.3 grams of sodium thioglycolate; broth (beef heart soup) 1000 ml. Prepare according to reagent instructions. Adjust the pH to 7.2-7.4, autoclave at 10 pounds for 15 minutes.

[0050] 2) Prepare carbon-free medium

[0051] Prepare as follows: add 3g NaCl, 1.0g NH to every liter of phosphate buffer (pH 7.5) 4 Cl, 0.3g L-cysteine hydrochloride; cover with paraffin oil, and autoclave at 121°C for 15min.

[0052] 2. Biotransformation

[0053] 1) Prepa...

Embodiment 3

[0063] Embodiment 3, the impact of the number of passages of human intestinal bacteria on the biotransformation effect

[0064] 1. Prepare culture medium

[0065] 1) Prepare anaerobic medium

[0066] With the step 1 of embodiment 1.

[0067] 2) Prepare carbon-free medium

[0068] Prepare as follows: add 1.5g NaCl, 0.5g NH to every liter of phosphate buffer (pH 7.0) 4 Cl, 0.1g sodium thioglycolate; cover with paraffin oil, and autoclave at 121°C for 15min.

[0069] 2. Strain passage

[0070] 1) Prepare the bacterial liquid of human sample 9 (final concentration is 4g feces / 20ml phosphate buffer), the preparation method is the same as that of step 2 of Example 1, and obtain the bacterial liquid of sample 9.

[0071] 2) Inoculate the bacterial solution of sample 9 into the anaerobic medium at a ratio of 1:10, and perform anaerobic culture at 40° C. (oxygen partial pressure is 7.03975 kPa) for 24 hours to enrich the bacteria.

[0072] 3) Inoculate the enriched bacterial solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com