Plasma processing apparatus, chamber internal part, and method of detecting longevity of chamber internal part

A plasma and processing device technology, which is applied in the field of plasma processing devices, can solve the problems of being unable to solve the problem of wasting abnormal discharge, and cannot accurately detect the life of components in the chamber of the plasma processing device, so as to prevent the life from reaching the end of life and prevent waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

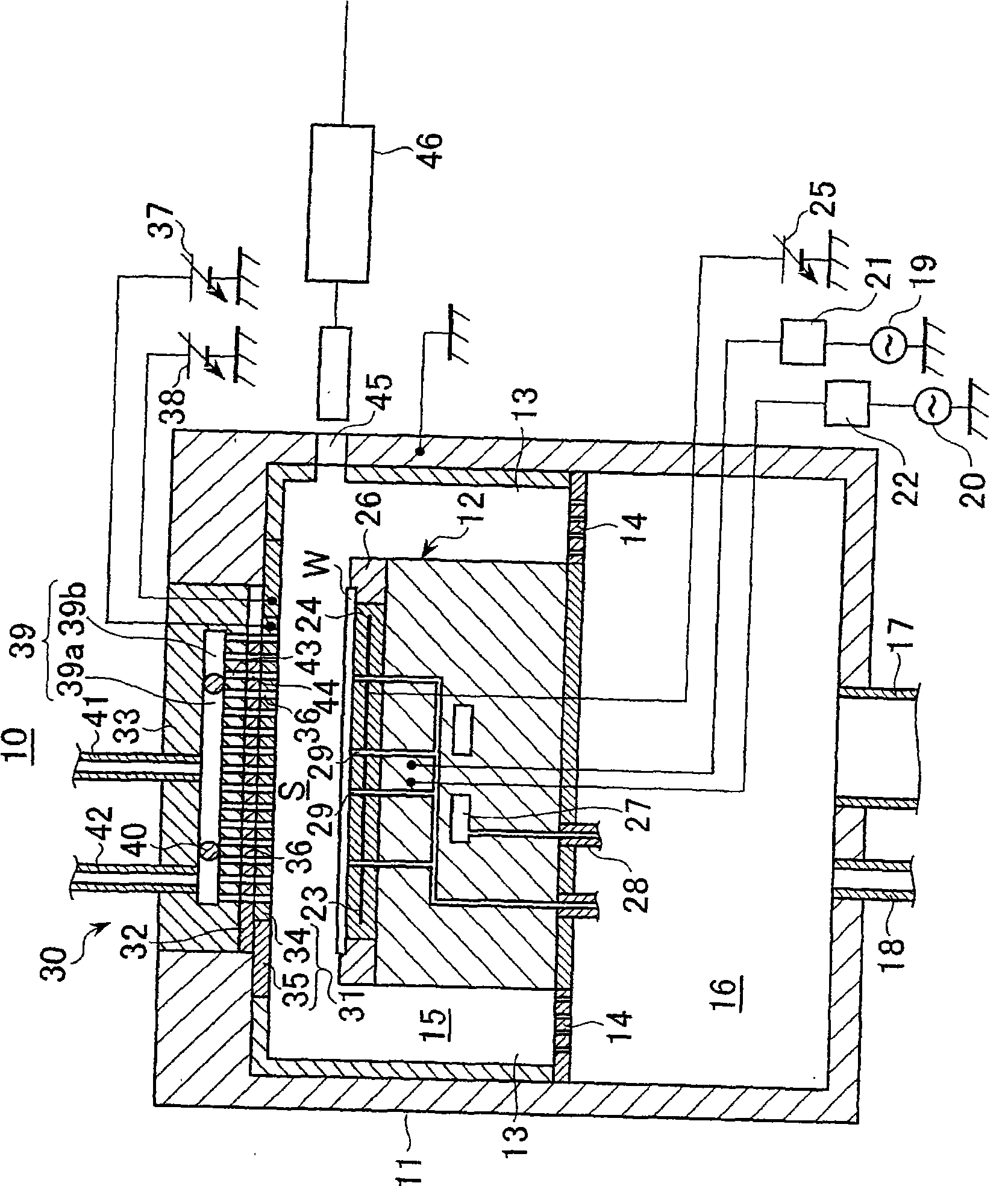

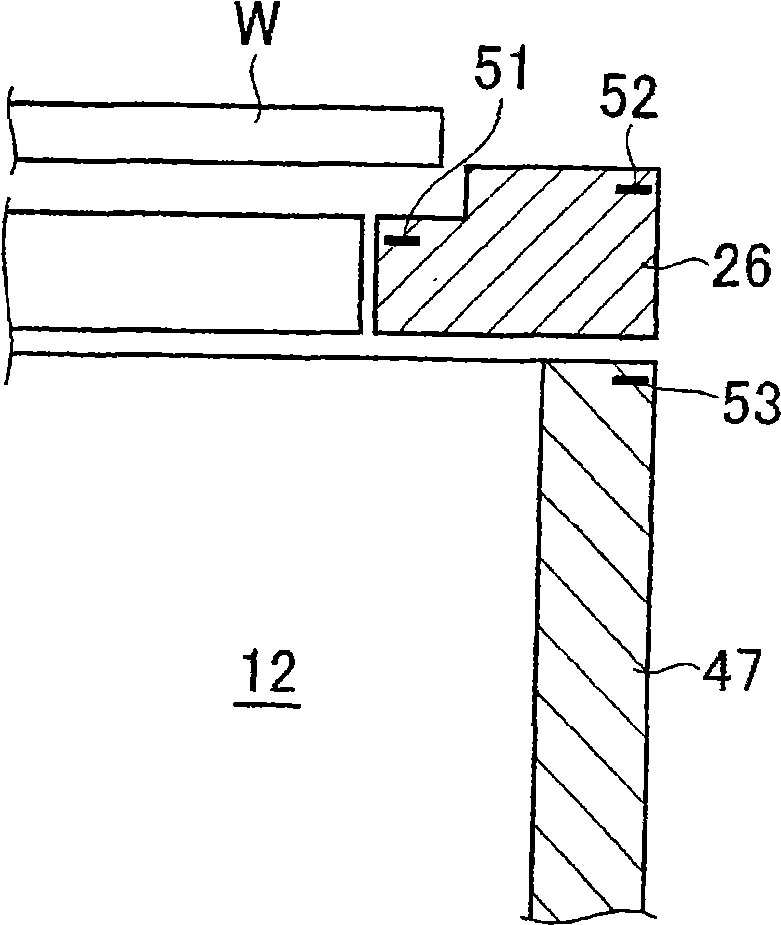

[0062] figure 1 It is a cross-sectional view showing a schematic configuration of a substrate processing apparatus which is a plasma processing apparatus according to an embodiment of the present invention. This substrate processing apparatus is configured to perform plasma processing such as RIE (Reactive Ion Etching) processing and ashing processing on a semiconductor wafer W serving as a substrate.

[0063] exist figure 1 Among them, the substrate processing apparatus 10 includes: a cylindrical processing chamber 11; Seat 12.

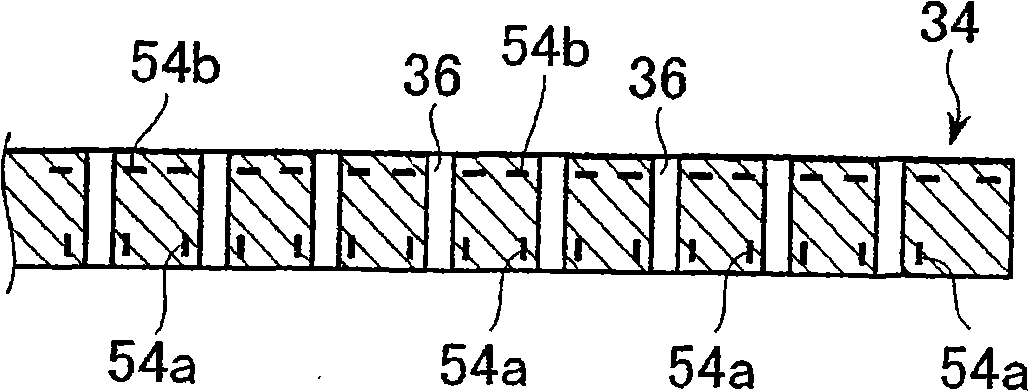

[0064] In the substrate processing apparatus 10 , an exhaust flow path 13 serving as a flow path for discharging gas in a processing space S described later to the outside of the processing chamber 11 is formed by the inner wall of the processing chamber 11 and the side surface of the susceptor 12 . An exhaust plate 14 is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com