Plasma torch life duration detecting device

A technology of plasma welding and detection device, which is applied to measurement devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as cost reduction, and achieve the effect of reducing detection mechanism and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

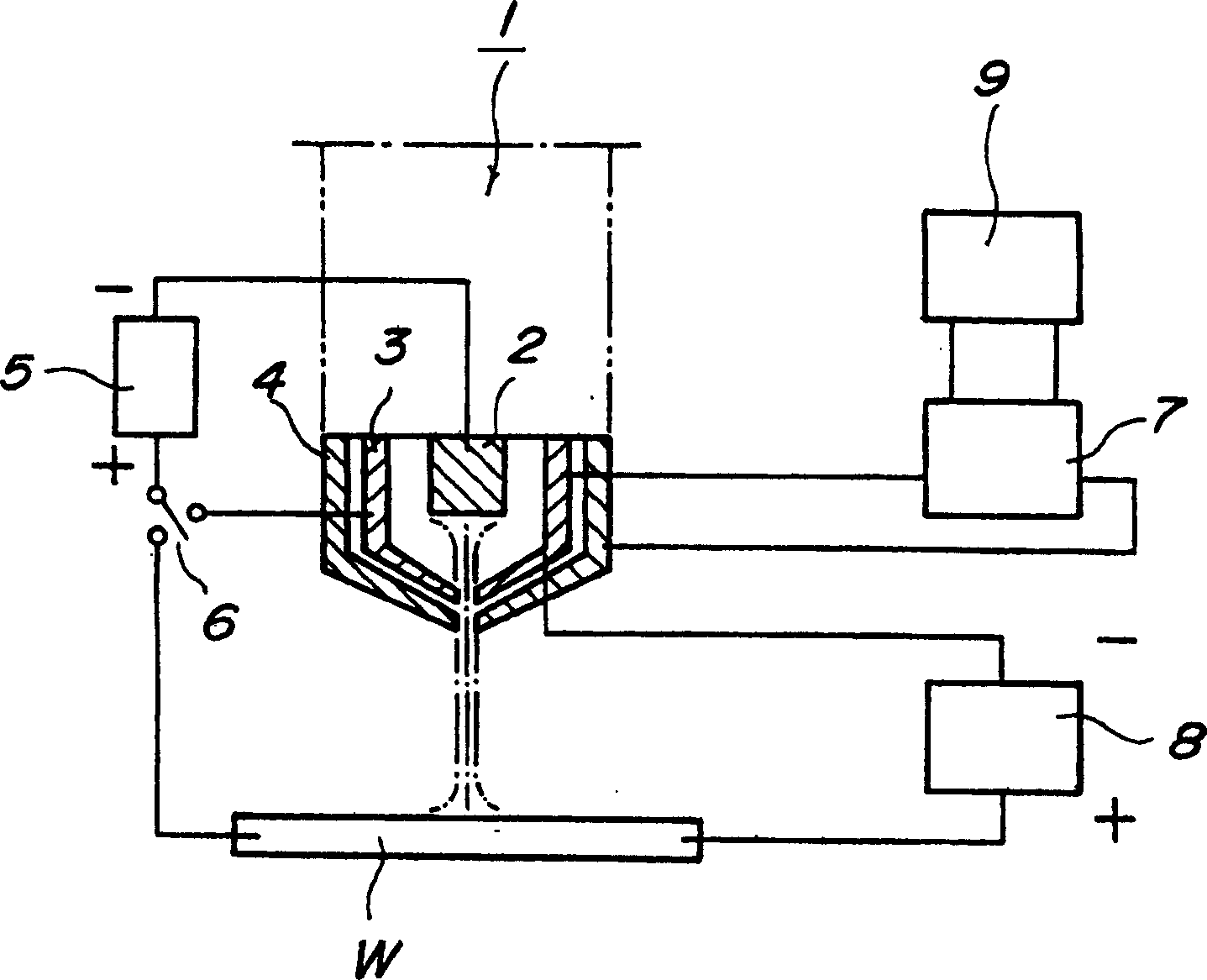

[0047] The life detection device of the plasma torch according to the present invention detects the electrode by measuring and monitoring the voltage between the nozzle member and the nozzle guard which are insulated from each other in a state where a plasma arc is formed between the electrode and the material to be processed. Consumption of the nozzle parts, nozzle guards, contact between the nozzle guard and the material to be processed, and by applying a voltage between the nozzle part and the material to be processed in the state where the plasma arc is not formed, A device that detects contact between the nozzle guard and the material being processed.

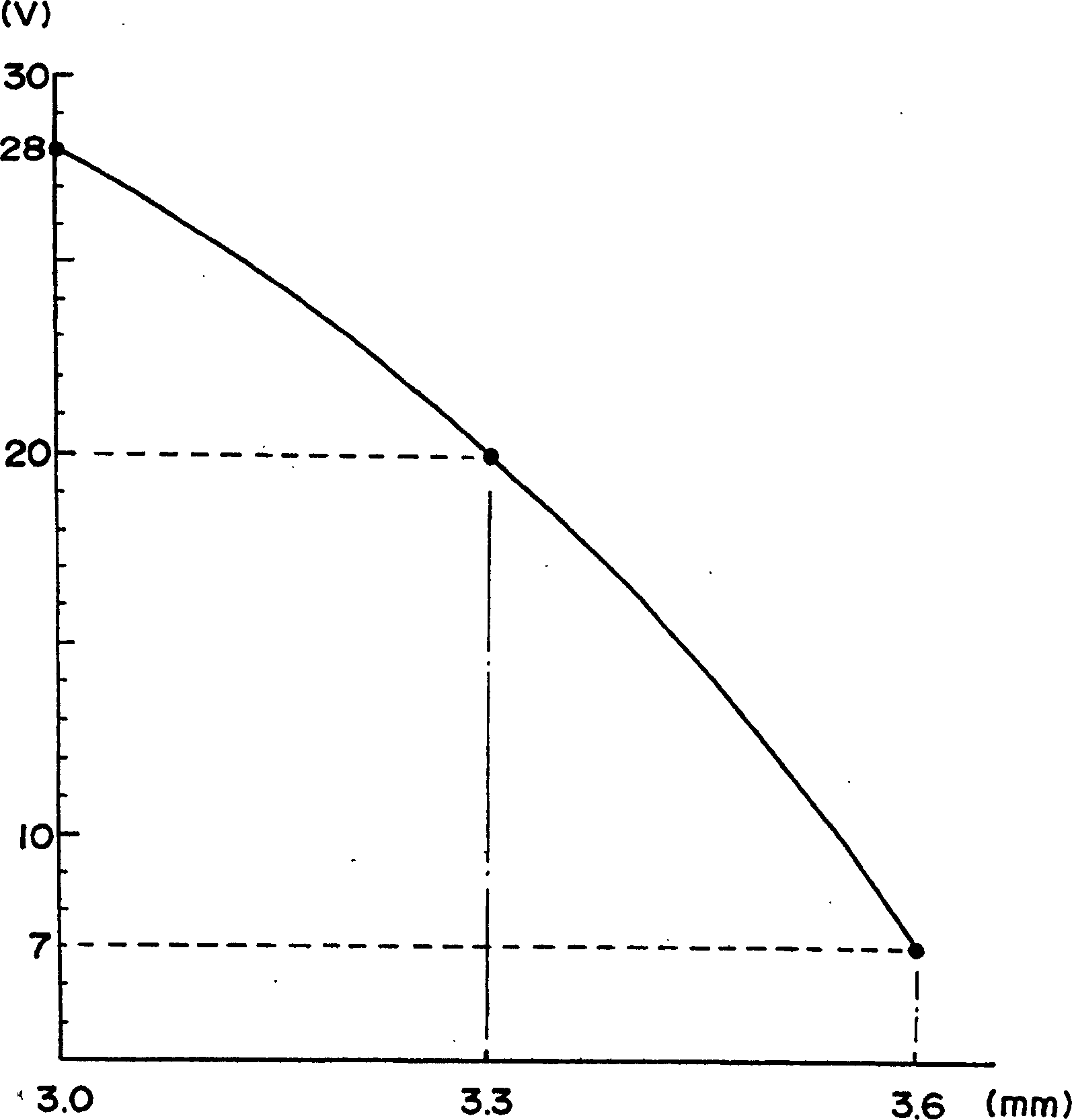

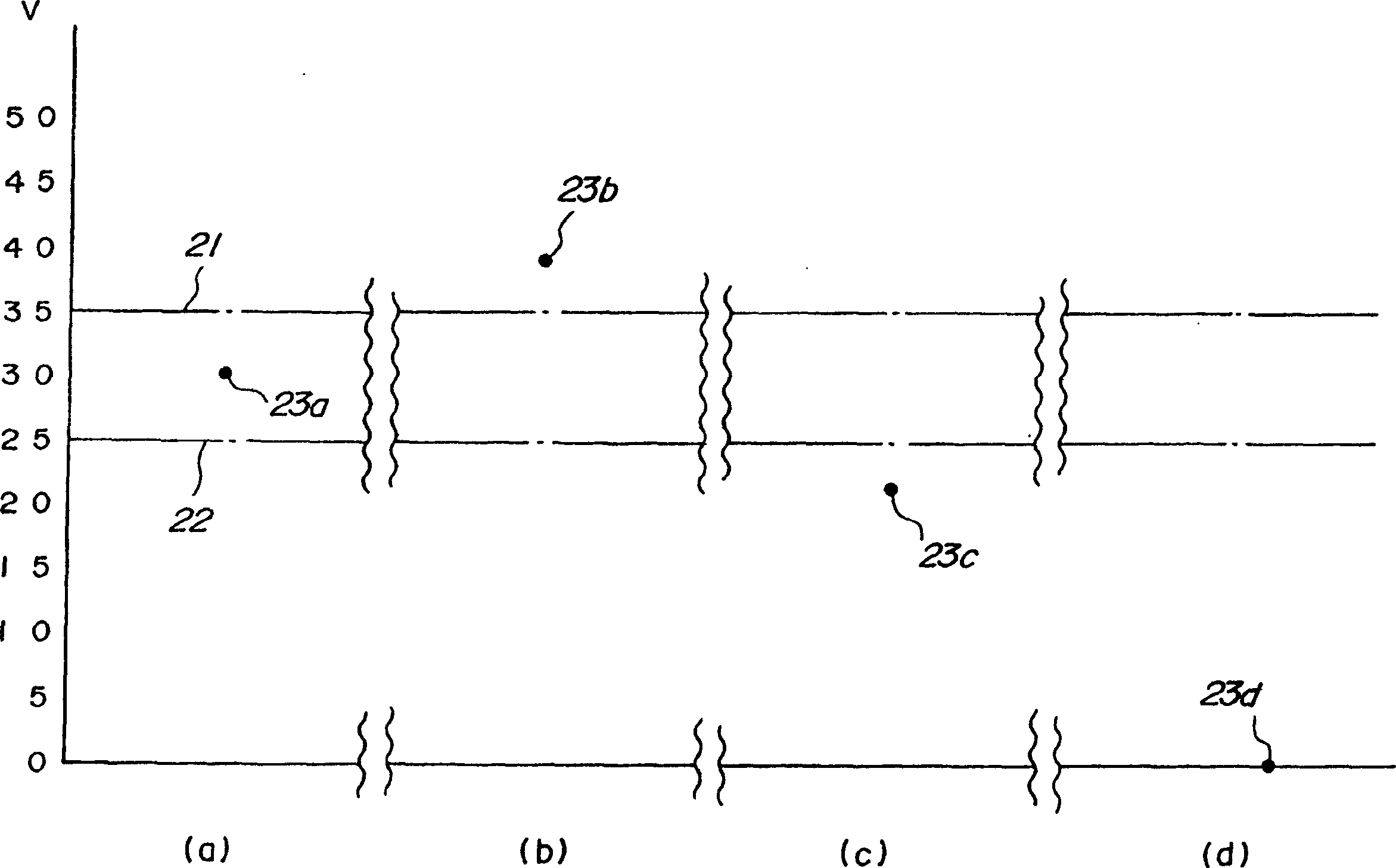

[0048] In the case of measuring and monitoring the voltage between the nozzle part and the nozzle guard, the processing accuracy of the workpiece can be maintained by setting the voltage value to be monitored to a value that can maintain the possible performance of processing that satisfies the purpose It also prevents pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com