Decorative sheet for construction material

A technology for decorative sheets and building materials, applied in decorations, applications, home walls, etc., can solve problems such as easy cracks and cracks, and achieve crack suppression, excellent scratch resistance and impact resistance, and high design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

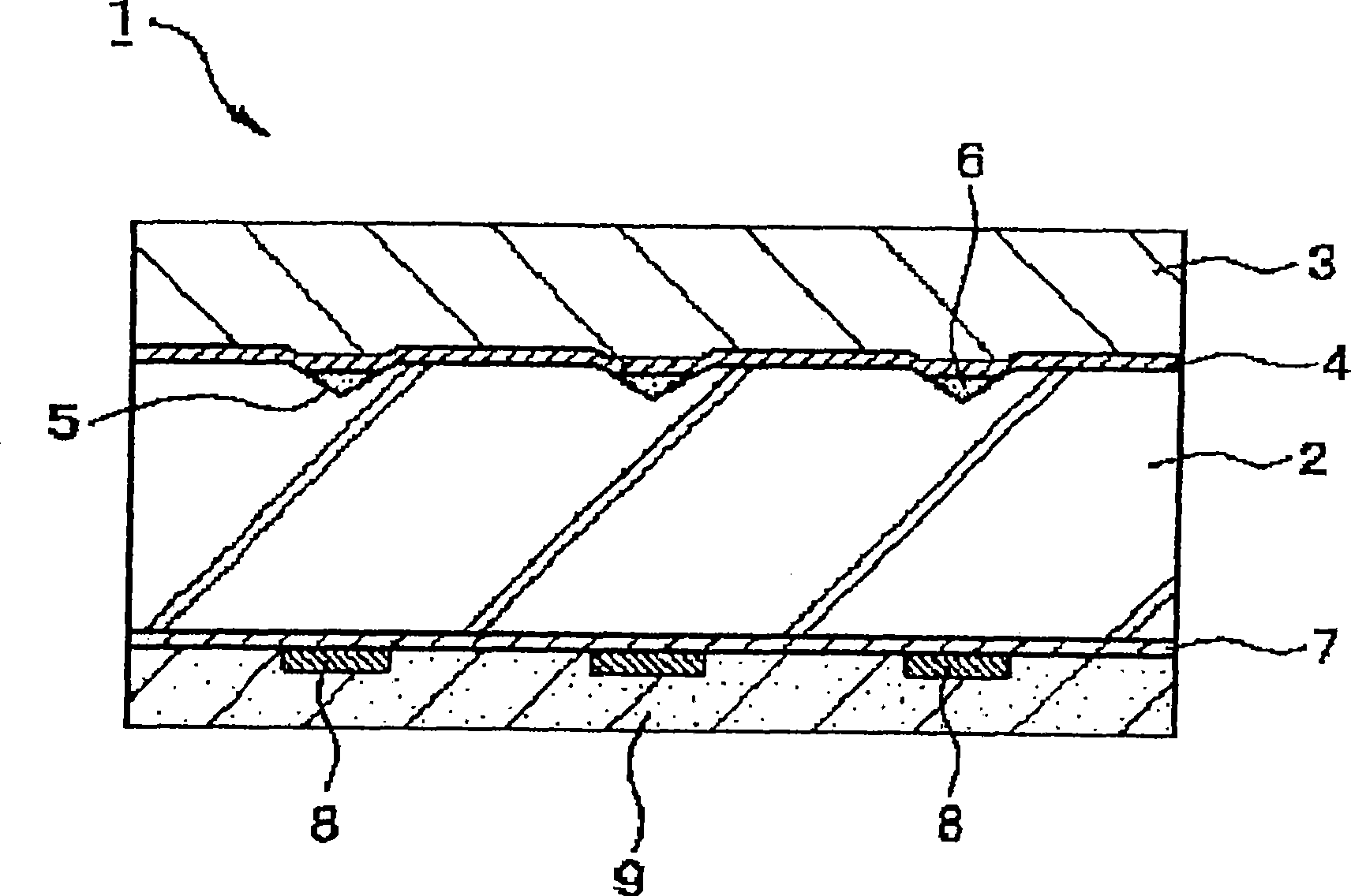

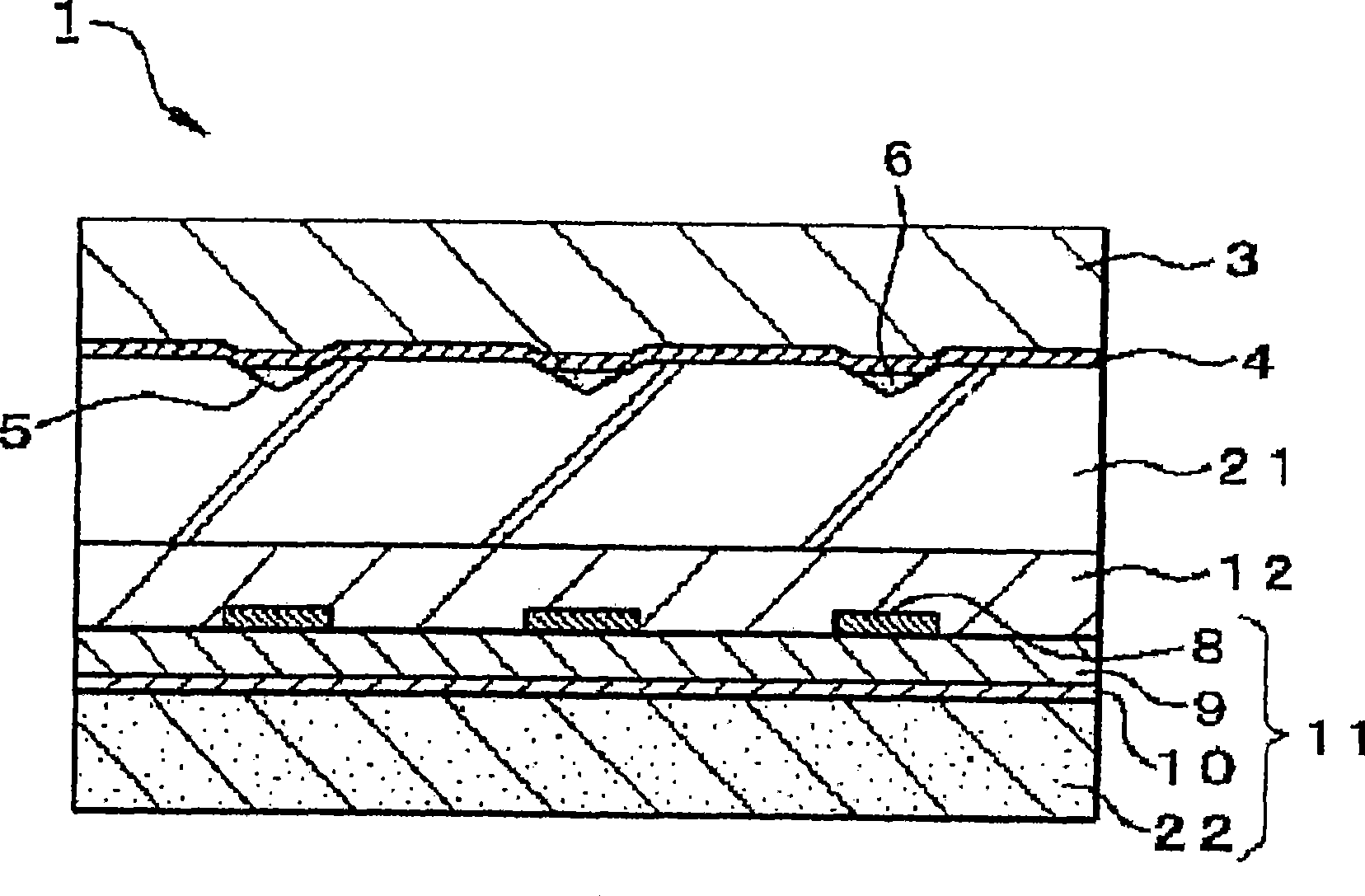

Embodiment 1

[0101] A decorative sheet for building materials was produced through the following steps.

[0102] Corona discharge treatment was applied to the front and back of the base sheet formed of a colored polypropylene film having a thickness of 60 μm. Next, on the surface of the sheet, 8 parts by weight of hexamethasone dissolved in a mixed solvent of methyl ethyl ketone and butyl acetate was applied to a total of 100 parts by weight of polyurethane resin and acrylic polyol resin by gravure printing. A solution of resin formed from methylene diisocyanate, so that the solid content is 2g / m 2 , forming a primer layer for forming a pattern pattern layer with a thickness of 2 μm. In addition, on the surface of the substrate sheet opposite to the design layer, by the gravure printing method, coated with a total of 100 parts by weight of polyurethane resin and nitrocellulose in a mixed solvent of methyl ethyl ketone and butyl acetate. A solution of 5 parts by weight of hexamethylene di...

Embodiment 2

[0117] A decorative sheet for building materials was produced in the same manner as in Example 1, except that the coating solution for the ionizing radiation-curable resin layer in Example 1 was replaced with the following coating solution composition (b).

[0118] [Coating solution composition (b) of ionizing radiation-curable resin layer]

[0119] 85 parts by weight of urethane acrylate oligomer (A)

[0120] ・UA306H (manufactured by Kyoeisha Chemical Co., Ltd., hexafunctional aliphatic urethane acrylate oligomer) 15 parts by weight

[0121] ・Silicon dioxide (manufactured by Fuji Silysia: SYLYSIA450) 10 parts by weight

[0122] 100 parts by weight of ethyl acetate

Embodiment 3

[0124] A decorative sheet for building materials was produced in the same manner as in Example 1, except that the coating solution for the ionizing radiation-curable resin layer in Example 1 was replaced with the following coating solution composition (c).

[0125] [Coating Liquid Composition (c) of Ionizing Radiation Curable Resin Layer]

[0126] 95 parts by weight of urethane acrylate oligomer (A)

[0127] · U-15HA (manufactured by Shin-Nakamura Chemical Industry, pentafunctional aliphatic urethane acrylate oligomer) 5 parts by weight

[0128] ・Silicon dioxide (manufactured by Fuji Silysia: SYLYSIA450) 10 parts by weight

[0129] 100 parts by weight of ethyl acetate

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com